Safe energy-saving automotive glass and manufacturing method thereof

A technology of automobile glass and manufacturing method, which is applied in windshield, chemical instrument and method, glass/slag layered products, etc., and can solve the problems of heat insulation, sound insulation, noise reduction, anti-glare, anti-condensation and fog Minimize impact resistance and other issues, achieve the effects of impact resistance, anti-condensation, and excellent visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The following steps are adopted to prepare safe and energy-saving automotive glass:

[0057] (1) Select cesium potassium glass, PVB film, and aerogel with thicknesses of 3mm, 4mm, and 4mm respectively, and paste Low-e film on one side of the cesium potassium glass;

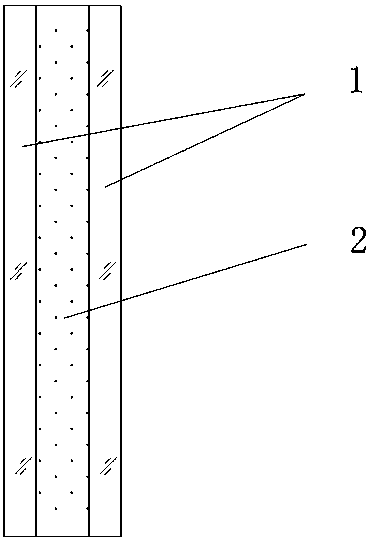

[0058] (2) Place airgel and PVB film on the cesium potassium glass in step (1) according to the shape of "back";

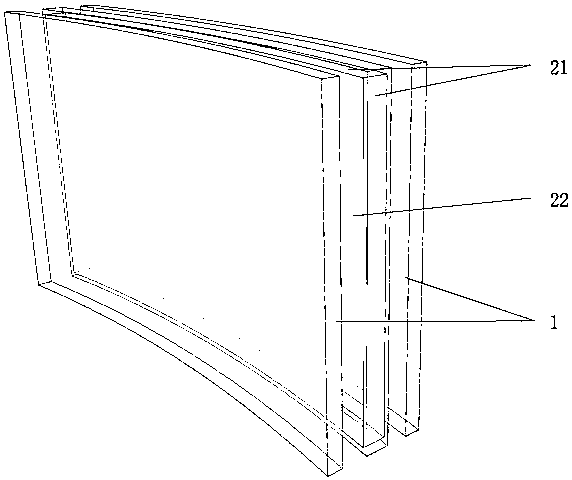

[0059] (3) Place another piece of cesium potassium glass above. Under vacuum conditions, the temperature is 135°C, the applied pressure is 5MPa, and the temperature and pressure are maintained for 30 minutes to obtain a safe and energy-saving automotive glass. The structure diagram is as follows figure 2 shown. Table 1 is the performance index of the safe and energy-saving automobile glass of Example 1.

[0060] Table 1 Performance indicators of the safe and energy-saving automotive glass of Example 1

[0061]

Embodiment 2

[0063] The following steps are adopted to prepare safe and energy-saving automotive glass:

[0064] (1) Select tempered ultra-clear glass, PVB film, and aerogel with thicknesses of 4mm, 4mm, and 4mm respectively, and paste Low-e film on one side of the tempered ultra-clear glass;

[0065] (2) Place airgel and PVB film on the cesium potassium glass in step (1) according to the shape of "Tian";

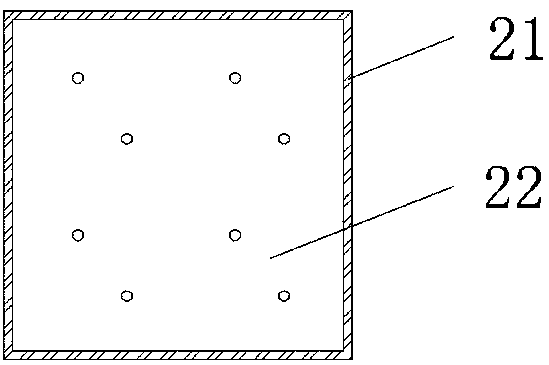

[0066] (3) Place another piece of tempered ultra-clear glass above, and place a bridge-breaking aluminum spacer frame with a thickness of 4mm around the airgel composite layer; under vacuum conditions, the temperature is 140°C, and the applied pressure is 3MPa. It takes 20 minutes to obtain safe and energy-saving automotive glass. The plan view of the airgel composite layer is as follows Figure 4 As shown, the cross-sectional view is as Figure 6 shown. Table 2 is the performance index of the safe and energy-saving automobile glass of Example 2.

[0067] Table 2 Performance indicat...

Embodiment 3

[0070] The following steps are adopted to prepare safe and energy-saving automotive glass:

[0071] (1) Select tempered glass, EVA film, and aerogel with thicknesses of 3mm, 4mm, and 4mm respectively, and paste Low-e film on one side of the above tempered glass;

[0072] (2) Place airgel and EVA film on the tempered glass in step (1) according to the shape of "back";

[0073] (3) Place another piece of tempered glass mentioned above. Under vacuum conditions, the temperature is 105°C, the applied pressure is 4.5MPa, and the temperature and pressure are maintained for 30 minutes to obtain a safe and energy-saving automotive glass. The structure diagram is as follows figure 2 shown. Table 3 is the performance index of the safe and energy-saving automobile glass of Example 3.

[0074] Table 3 Performance indicators of the safe and energy-saving automotive glass of Example 3

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com