Diamine monomer, preparation method therefor, polyimide and preparation method therefor

A technology of diamine monomer and dinitro group, applied in chemical instruments and methods, organic chemistry, membrane technology, etc., can solve the problems of low permeability of polyimide film and poor solubility of polyimide film, etc. Achieve the effect of improving optical transmittance, good visible light transmittance, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

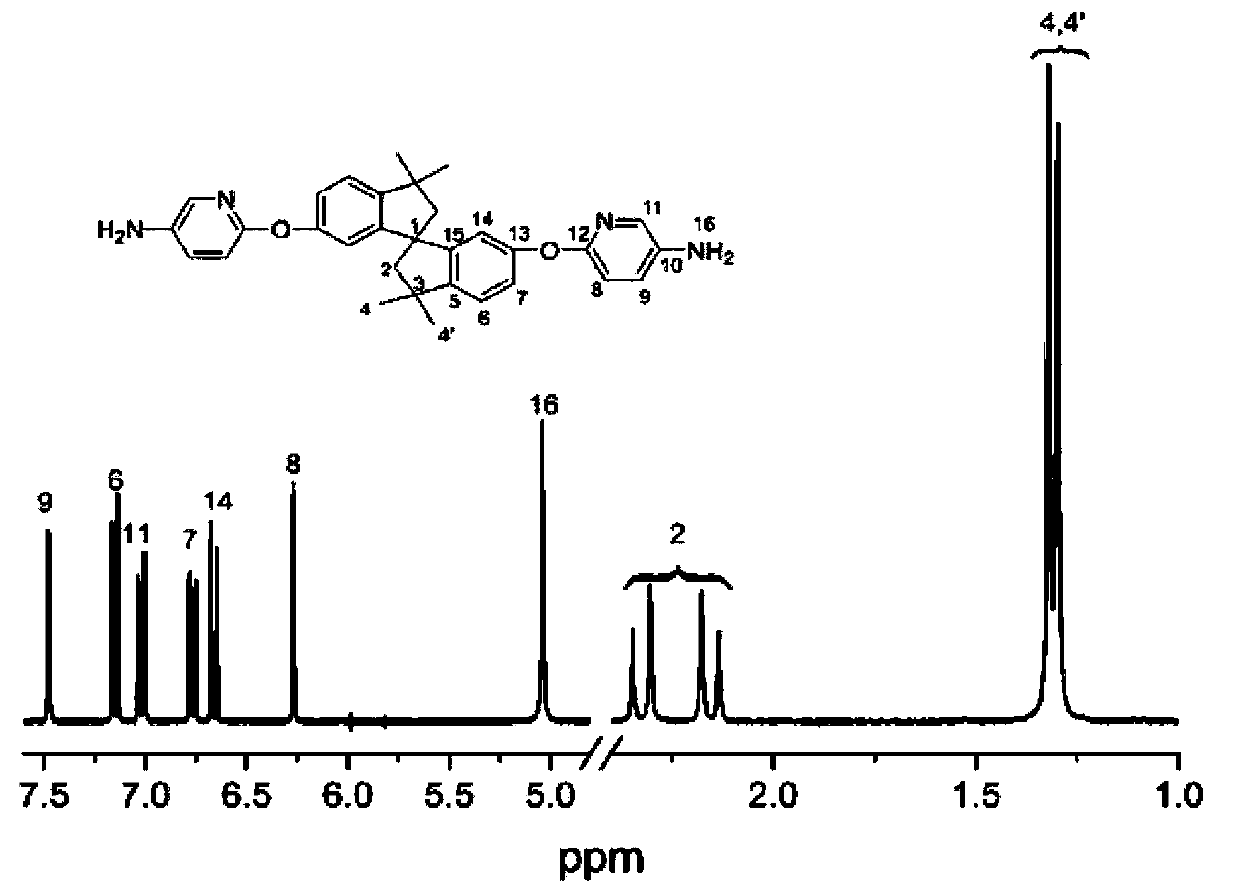

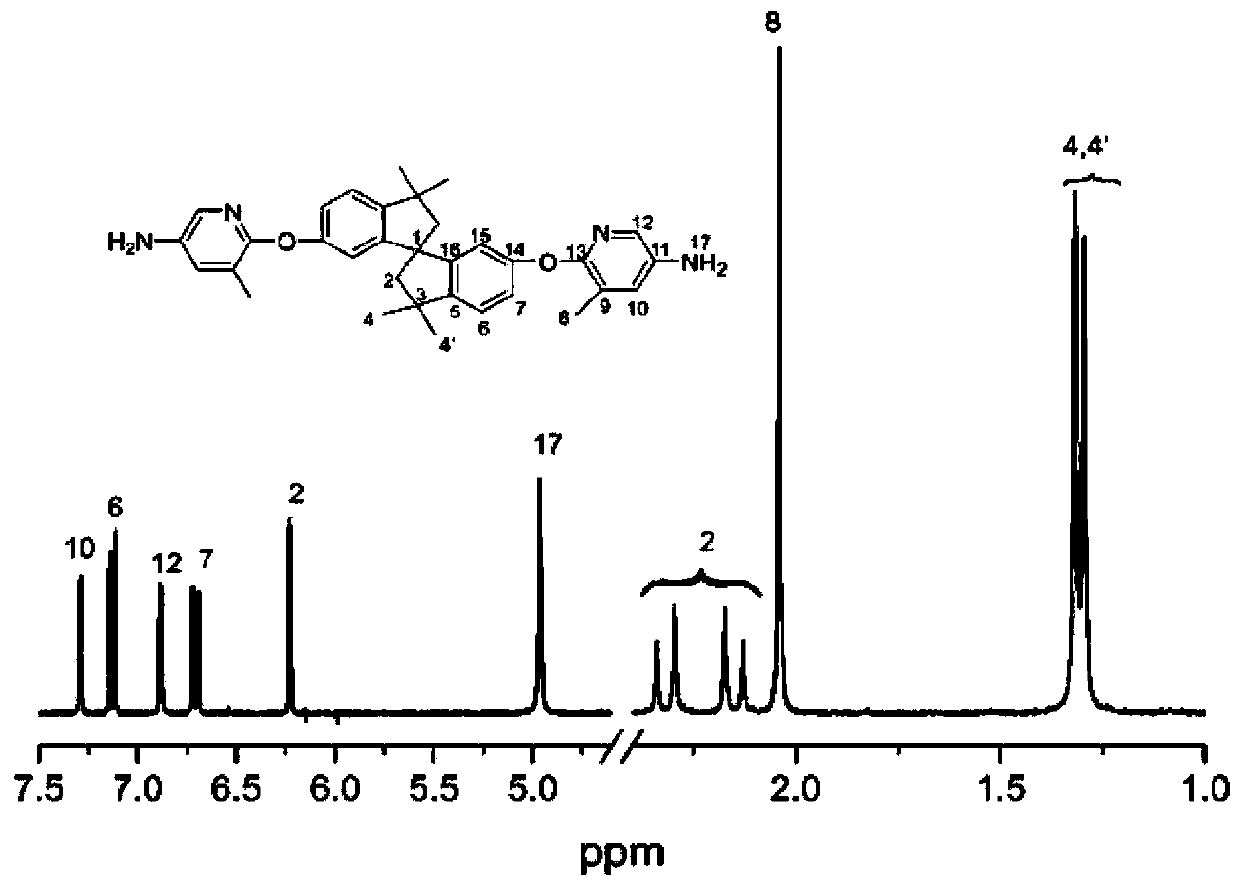

[0045] The present invention provides a method for preparing the diamine monomer described in the above technical solution. In the present invention, when R' in the formula I is a methyl group, the method for preparing the diamine monomer includes the following steps:

[0046] (1) microwave reaction of bisphenol A and methanesulfonic acid, the microwave reaction product is discharged in an ice-water bath, and the solid is collected; the solid is heated and sublimated to obtain a methyl diphenol compound;

[0047] (2) mixing the methyl diphenol compound obtained in the step (1), a catalyst and a solvent to obtain a phenolic ionic liquid; performing a substitution reaction with the phenolic ionic liquid and a mononitro compound to obtain a dinitro compound and then reducing the dinitro compound to obtain a diamine monomer whose structure R' is methyl as shown in formula I; the catalyst is potassium carbonate and / or cesium carbonate.

[0048] In the invention, bisphenol A and met...

Embodiment 1

[0098] Embodiment 1: the preparation of methyl diphenol compound

[0099] Add 10mmol of bisphenol A and 50mmol of methanesulfonic acid into a 250mL three-necked flask equipped with a mechanical stirring device, and react at room temperature for half an hour under the protection of sufficient nitrogen gas. The heating rate is raised to the melting temperature of the system above 180°C, and the reaction is completed when the raw material point disappears as detected by TLC, and the reaction is stopped. Place in a vacuum tube furnace, heat and sublimate the crude product, collect the sublimation product to obtain a methyl diphenol compound, and dry it in vacuum at 100°C for 12 hours to obtain 1.5980 g of a methyl diphenol compound. The structure of the obtained product is as follows:

[0100]

Embodiment 2

[0101] Embodiment 2: the preparation of trifluoromethyl diphenol compound

[0102] Add 10mmol of bisphenol AF and 100mmol of trifluoroacetic acid into the tetrafluoro reaction vessel equipped with a mechanical stirring device, fully stir and dissolve at room temperature, place the tetrafluoro reaction vessel with the reaction raw materials in a high-temperature reaction kettle, and adjust the heating of the system The temperature is 200°C, the melting reaction is carried out for 15 hours, and the reaction is stopped; after the reaction, the system is discharged into an ice-water bath, filtered and dried to obtain a crude product, which is fully dissolved in a good solvent 1,4-dioxane , add poor solvent deionized water until it just precipitates and stirs to precipitate insoluble, suction filtration, drying to obtain trifluoromethyl diphenol compound, the obtained product structure is as follows:

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com