Paddy rice fertilizer capable of inhibiting ineffective tillering

An ineffective tillering and paddy rice technology, applied in the direction of inorganic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of time-consuming, labor-intensive, yield reduction, and reduced economic benefits of rice planting, and achieve lower management technical requirements, higher economic benefits, and higher tiller yields. The effect of ear rate and seed setting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

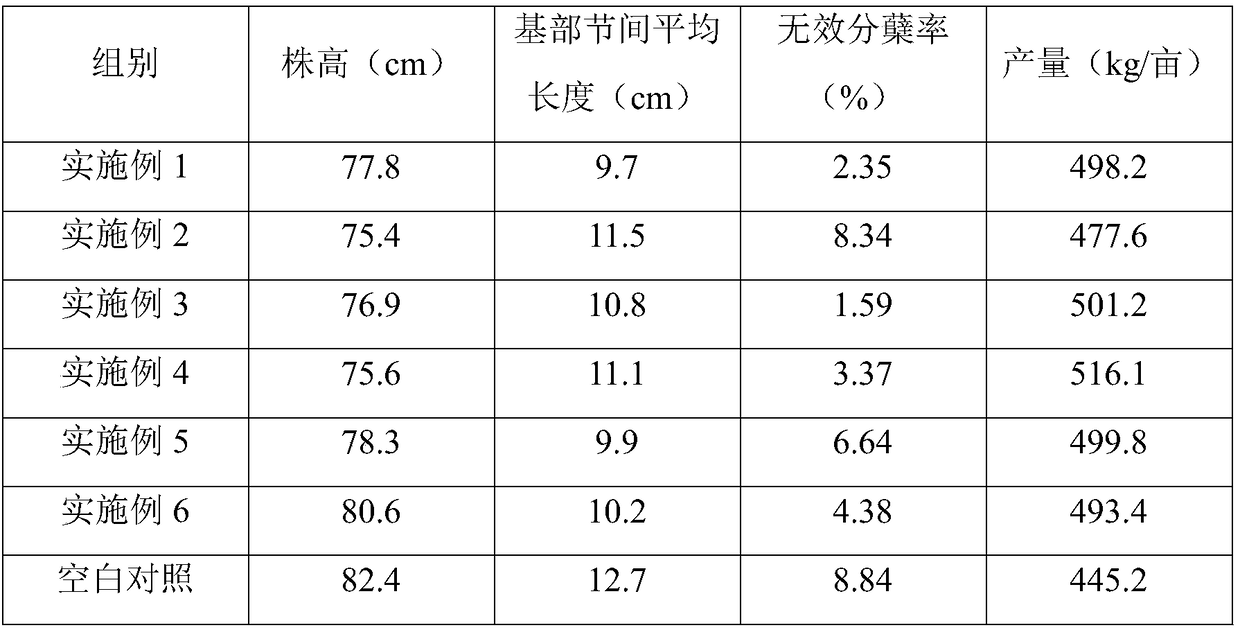

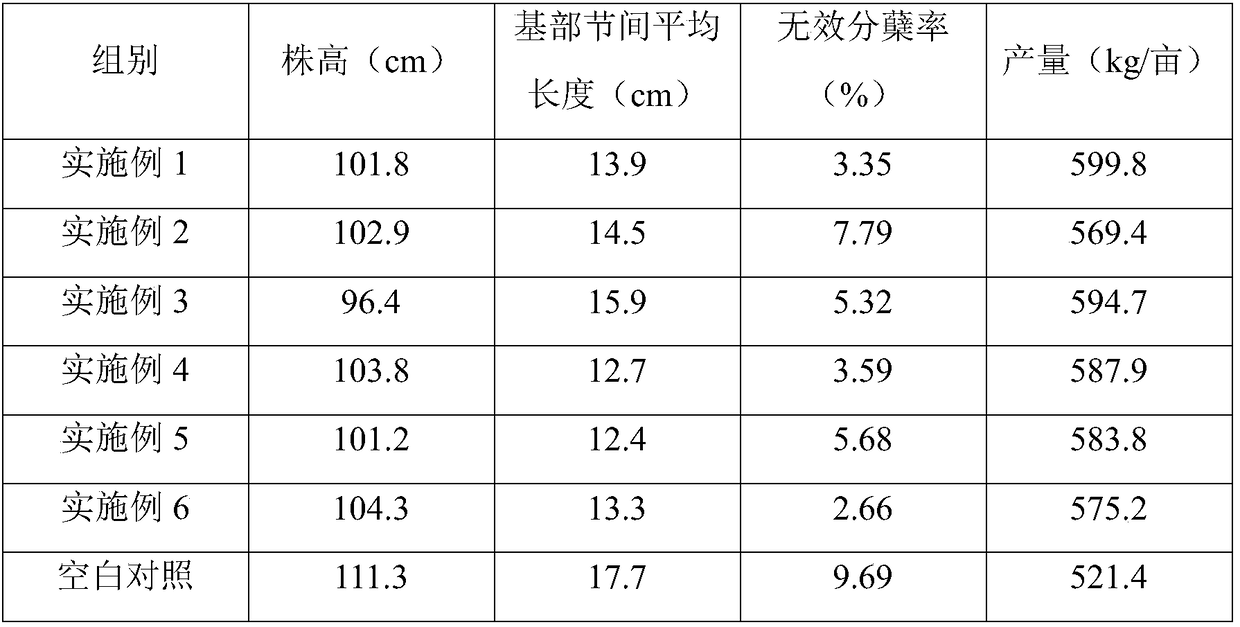

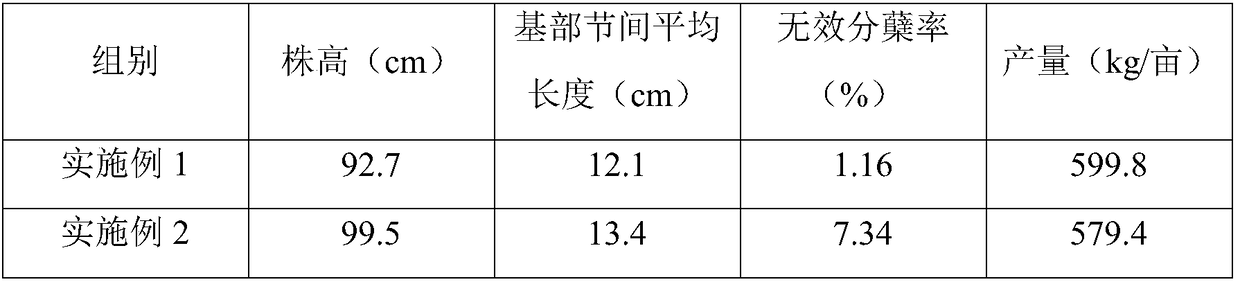

Examples

Embodiment 1

[0029] Embodiment 1: prepare fertilizer as follows

[0030] The parts by weight of each component are as follows: 20 parts of strigolactone, Na 2 SiO 3 9H 2 125 parts of O, 100 parts of diatomite containing 45% effective silicon, 44 parts of urea, 70 parts of potassium chloride, 30 parts of superabsorbent resin, 30 parts of zinc sulfate, 14 parts of sodium p-chlorophenoxyacetic acid, 0.5wt % abscisic acid wettable powder 6 parts, willow bark extract 60 parts, degree of polymerization 8-10, 18 parts of amino oligosaccharins with an average molecular weight of 2000Da, and 15 parts of maleic hydrazide.

[0031] The superabsorbent resin is a graft copolymer of high pullulan, acrylic acid and acrylamide in a weight ratio of 5:1:2.

[0032] The preparation steps are as follows:

[0033] (1) Dissolve 1g of p-chlorophenoxyacetic acid sodium salt in 100ml of hot water at 60°C, dilute to 500mL to prepare mother liquor, and dilute it 500 times for use;

[0034] (2) Preparation of wi...

Embodiment 2

[0042] Embodiment 2: prepare fertilizer as follows:

[0043] The parts by weight of each component are as follows:

[0044] 0.1 part of strigolactone, Na 2 SiO3 9H 2 50 parts of O, 50 parts of diatomite diatomite containing 30% effective silicon, 30 parts of urea, 50 parts of potassium chloride, 10 parts of superabsorbent resin, 10 parts of zinc sulfate, 10 parts of sodium p-chlorophenoxyacetic acid , 1 part of 0.1wt% abscisic acid wettable powder, 10 parts of willow bark extract, 5 parts of amino oligosaccharin with an average molecular weight of 1000 Da, and 10 parts of maleic hydrazide.

[0045] The superabsorbent resin is a graft copolymer of high pullulan, acrylic acid and acrylamide in a weight ratio of 10:1:2.

[0046] Preparation method is with embodiment 1.

Embodiment 3

[0047] Embodiment 3: prepare fertilizer as follows:

[0048] The parts by weight of each component are as follows:

[0049] 50 parts of strigolactone, Na 2 SiO 3 9H 2 200 parts of O, 150 parts of diatomite diatomite containing 60% effective silicon, 60 parts of urea, 100 parts of potassium chloride, 50 parts of superabsorbent resin, 50 parts of zinc sulfate, 20 parts of sodium p-chlorophenoxyacetic acid , 10 parts of 1wt% abscisic acid wettable powder, 100 parts of willow bark extract, 30 parts of amino oligosaccharin with an average molecular weight of 1500 Da, 20 parts of maleic hydrazide, 6 to 9 degrees of polymerization.

[0050] The superabsorbent resin is a graft copolymer of high pullulan, acrylic acid and acrylamide in a weight ratio of 8:3:2.

[0051] Preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com