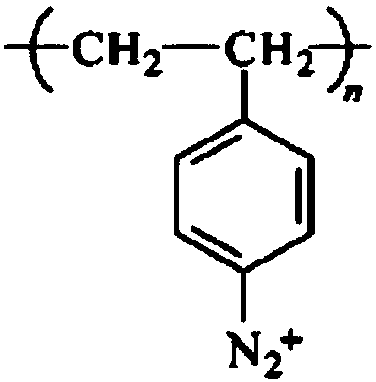

Polystyrene-diazonium-salt-based hydrophilic modification method for polyurethane

A polystyrene and hydrophilic modification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of cumbersome steps and many reagents, and achieve high reactivity , simple steps, high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1: Take the synthesized polystyrene diazonium salt solution, and soak the polyurethane carrier with a side length of 10mm in the diluted solution for 0.5h at 2°C;

[0050] Step 2: After soaking, take out the polyurethane carrier, wash it with water, blow it with cold wind for 1 minute, then immerse the polyurethane carrier in the solution of sodium polystyrene sulfonate, absorb and soak for 2 hours at 2°C, take it out and dry it, and it is completed Hydrophilic modification of polyurethane supports.

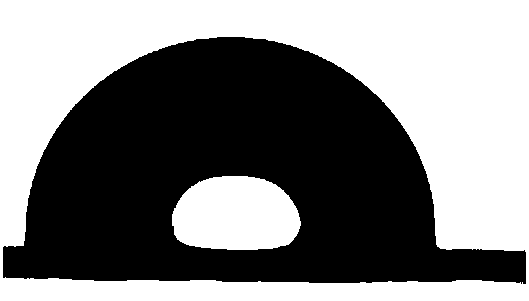

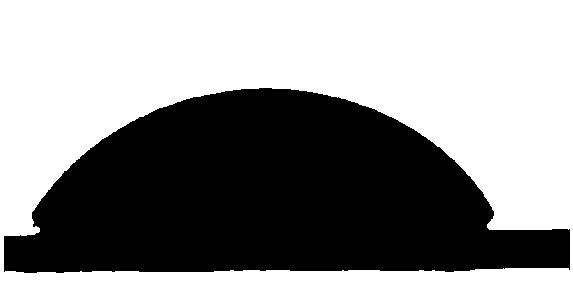

[0051] The contact angle of the polyurethane film after hydrophilic modification was measured, the contact angle of the bulk film was 92°, the contact angle of the modified polyurethane surface was 50°, and the effect of hydrophilic modification was obvious.

[0052] The polyurethane carrier modified by hyperbranched diazonium salt and polystyrene diazonium salt under the same conditions was placed in an acidic aqueous solution with a pH of 1, and the polyurethane car...

Embodiment 2

[0054] Step 1: Take the synthesized polystyrene diazonium salt solution, and soak the polyurethane carrier with a side length of 15mm in the diluted solution for 3 hours at 4°C;

[0055] Step 2: After soaking, take out the polyurethane carrier, wash it with water, blow it with cold wind for 5 minutes, then immerse the polyurethane carrier in the solution of sodium polyacrylate, absorb and soak for 10 hours at 4°C, take it out and dry it, and complete the polyurethane carrier. Hydrophilic modification.

[0056] The contact angle of the polyurethane film after hydrophilic modification was measured. The contact angle of the bulk film was 92°, and the contact angle of the modified polyurethane surface was 53°. The effect of hydrophilic modification was obvious.

Embodiment 3

[0058] Step 1: Take the synthesized polystyrene diazonium salt solution, and soak the polyurethane carrier with a side length of 20mm in the diluted solution for 1 hour at 3°C;

[0059] Step 2: After soaking, take out the polyurethane carrier, wash it with water, blow it with cold wind for 2 minutes, then immerse the polyurethane carrier in the solution of sodium polymethacrylate, absorb and soak for 6 hours at 3°C, take it out and dry it, and the polyurethane is completed Hydrophilic modification of the carrier.

[0060] The contact angle of the polyurethane film after hydrophilic modification was measured. The contact angle of the bulk film was 92°, and the contact angle of the modified polyurethane surface was 48°. The effect of hydrophilic modification was obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com