Matt finish scratch-resistant film with high surface energy and preparation method thereof

A high surface energy, anti-scratch technology, applied in the field of packaging, can solve problems such as long curing time and prolong production cycle, achieve good anti-scratch performance, improve production efficiency, and low gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

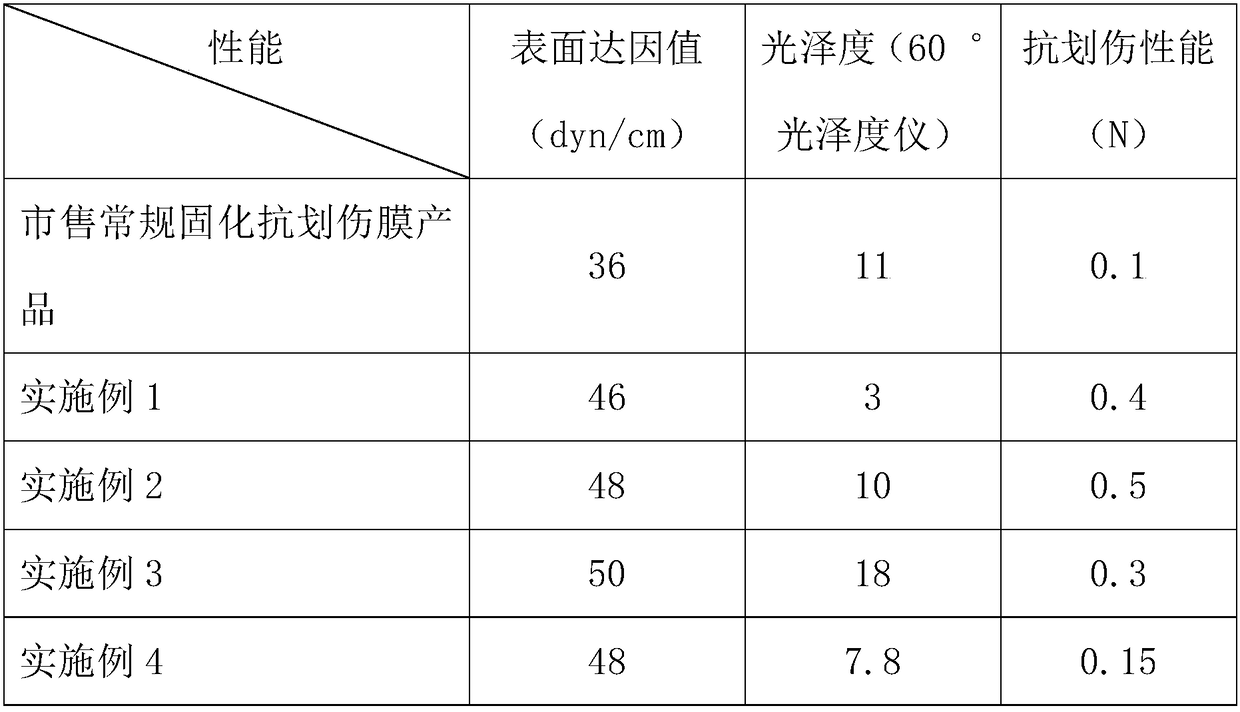

Examples

Embodiment 1

[0052] A matte scratch-resistant film with high surface energy is a matte scratch-resistant film, comprising a matte scratch-resistant functional coating and a film substrate;

[0053] A method for preparing a matte scratch-resistant film with high surface energy, comprising the steps of:

[0054] 1) Coat the methacrylate curing system coating on the outside of the biaxially stretched polypropylene film with a thickness of 15 μm. The coating thickness is controlled at 2 μm, and then dried at 80 ° C for 5 seconds. The stretched polypropylene film is cured at a speed of 80m / min through a curing device with an oxygen concentration of ≤1000ppm, and the cured coating is subjected to corona treatment at a power of 2-5KW to obtain a 17um thick coating with high surface energy. matte anti-scratch film.

[0055] Wherein, in the methacrylate curing system coating, the non-volatile component content is 100%, and the average functionality is 3, including the NeoRad U-6288 (DSM company pr...

Embodiment 2

[0058] When a matte scratch-resistant film with high surface energy is a matte scratch-resistant functional precoating film, it includes a matte scratch-resistant functional coating and a film-based precoating film; the film-based precoating film is made of polyparaphenylene It is composed of ethylene glycol diformate film, primer layer and hot melt adhesive layer.

[0059] A method for preparing a matte scratch-resistant film with high surface energy, comprising the steps of:

[0060] Firstly, an aqueous solution of polyethyleneimine is coated on the inner side of a 100um polyethylene terephthalate film (PET), and dried in an oven to form a 0.01um primer layer. The ethylene-vinyl acetate copolymer is coated on the primer layer by extrusion compounding process to form a 100um hot melt adhesive layer to obtain a 200um thick PET pre-coated film. Apply the acrylate-epoxy compound system coating on the outside of the PET pre-coating film with a coating thickness of 10um, and dry ...

Embodiment 3

[0064] When a matte scratch-resistant film with high surface energy is a matte scratch-resistant functional precoating film, it includes a matte scratch-resistant functional coating and a film-based precoating film; the film-based precoating film is made of nylon film, Composed of base coat and hot melt adhesive layer. .

[0065] A method for preparing a matte scratch-resistant film with high surface energy, comprising the steps of:

[0066] First, the mixed system of methacrylate-vinyl compound is coated on the outside of a 12 μm thick nylon film, the coating thickness is 5um, and dried at 80°C for 5s. The speed is cured by a curing device with an oxygen concentration of ≤500ppm, and the cured coating is flame-treated at a power of 5-10KW to obtain a 17um thick matte scratch-resistant film with high surface energy. Then, the polyurethane aqueous solution is coated on the inner side of the nylon film, and an undercoat layer is formed after being dried in an oven. The ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com