Lithium ion three-electrode laminate polymer battery and testing method thereof

A soft-pack battery and three-electrode technology, which is applied in the field of lithium-ion batteries, can solve problems such as inability to accurately simulate polarization conditions, and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

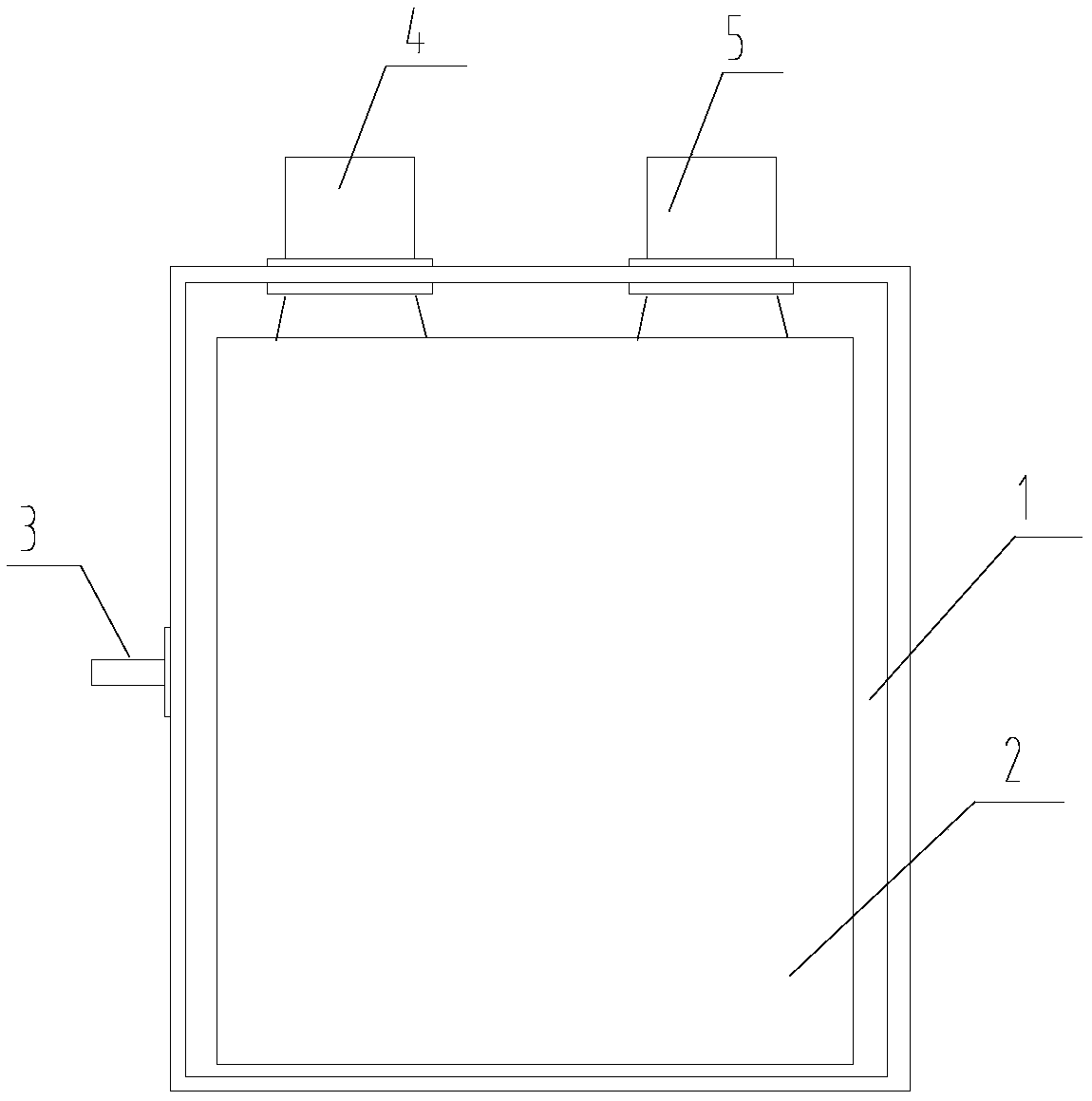

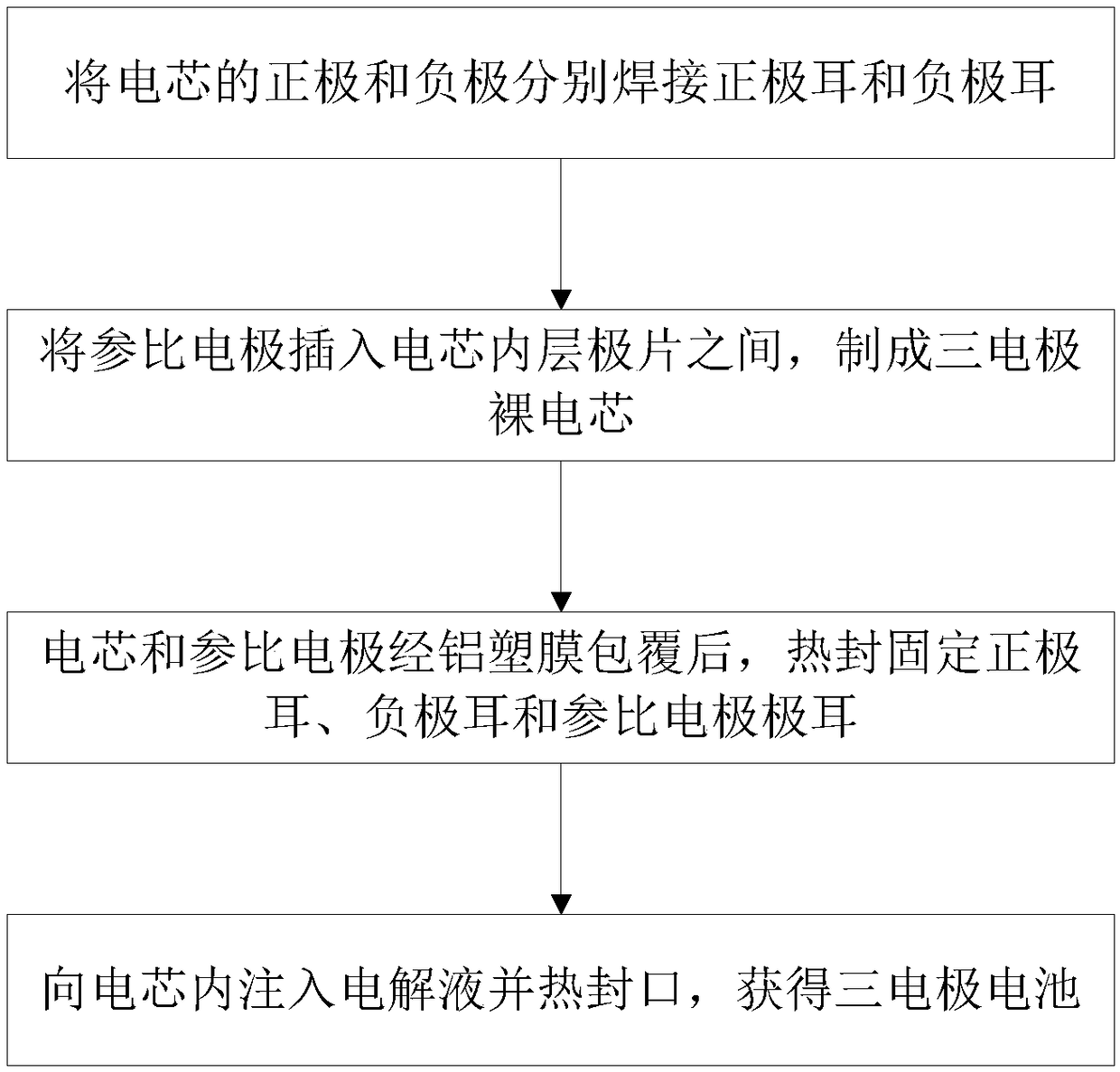

[0039] Use a lamination machine to stack the positive and negative plates and the cell 2 separators into a soft-packed battery, and weld the positive and negative poles of the soft-packed battery to the positive and negative tabs respectively, of which the positive and negative tabs are The thickness is 0.4-1 mm, and the width is 20-30 mm.

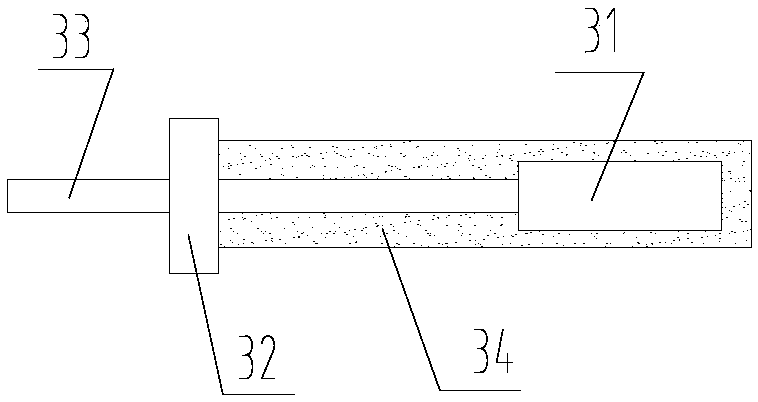

[0040] Fold the lithium sheet 31 to cover one end of the reference electrode lug, roll the lithium sheet 31 with a cylinder, make the lithium sheet 31 and the reference electrode ear closely fit, and finally wrap one end of the reference electrode ear with the lithium sheet 31 One layer of diaphragm 34 is covered to obtain reference electrode 3, such as figure 1 shown. The thickness of the tab of the reference electrode is 0.1-0.5 mm, and the width is 2-5 mm. The lithium sheet 31 has a length of 8-13 mm, a width of 5-12 mm, and a thickness of 0.5-1 mm.

[0041] Insert one end of the lithium sheet 31 of the reference electrode 3 prepared...

Embodiment 2

[0047] A three-electrode pouch battery was prepared in the same manner as in Example 1, and the formation, aging, and capacity separation were performed.

[0048] Connect the three voltage channels of the multi-channel voltage recorder to positive / negative, positive / reference electrode, and negative / reference electrode respectively.

[0049] Connect the positive and negative electrodes of the soft pack to the automatic charging and discharging equipment, and perform constant current charging and discharging at a rate of 1C at room temperature.

[0050]The data of each test channel is derived from the multi-channel voltage recorder, and the potentials of the positive and negative electrodes relative to the reference electrode during the formation process can be obtained. Find the time when the potential of the negative electrode relative to the reference electrode drops to 0V during the charging process, and the potential difference between the positive and negative electrodes,...

Embodiment 3

[0052] A three-electrode pouch battery was prepared in the same manner as in Example 1, and the formation, aging, and capacity separation were performed.

[0053] Place the three-electrode soft pack in a 0°C incubator, and after standing for 2 hours, connect the three voltage channels of the multi-channel voltage recorder to positive / negative, positive / reference electrode, and negative / reference electrode respectively.

[0054] Connect the positive and negative poles of the soft pack to the automatic charging and discharging equipment, and perform constant current charging and discharging at a rate of 2C.

[0055] The data of each test channel is derived from the multi-channel voltage recorder, and the potentials of the positive and negative electrodes relative to the reference electrode during the formation process can be obtained. Find the time when the potential of the negative electrode relative to the reference electrode drops to 0V during the charging process, and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com