Method for improving color and tenderness of DFD (dark firm dry) meat

A color and tenderness technology, which is applied to the functions of food ingredients, food ingredients as color, food science, etc., can solve the problem of not completely inhibiting DFD meat, improve color and tenderness, prevent excessive oxidation, and increase protein The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

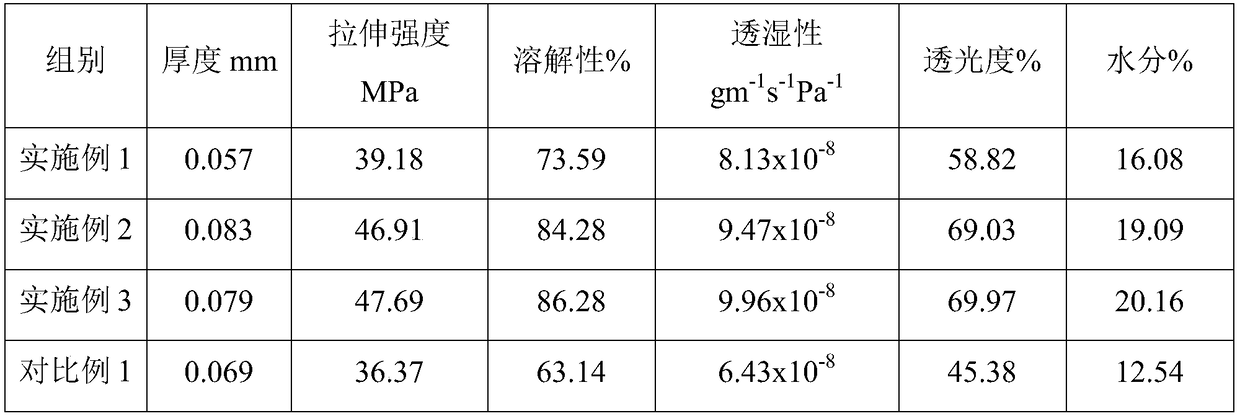

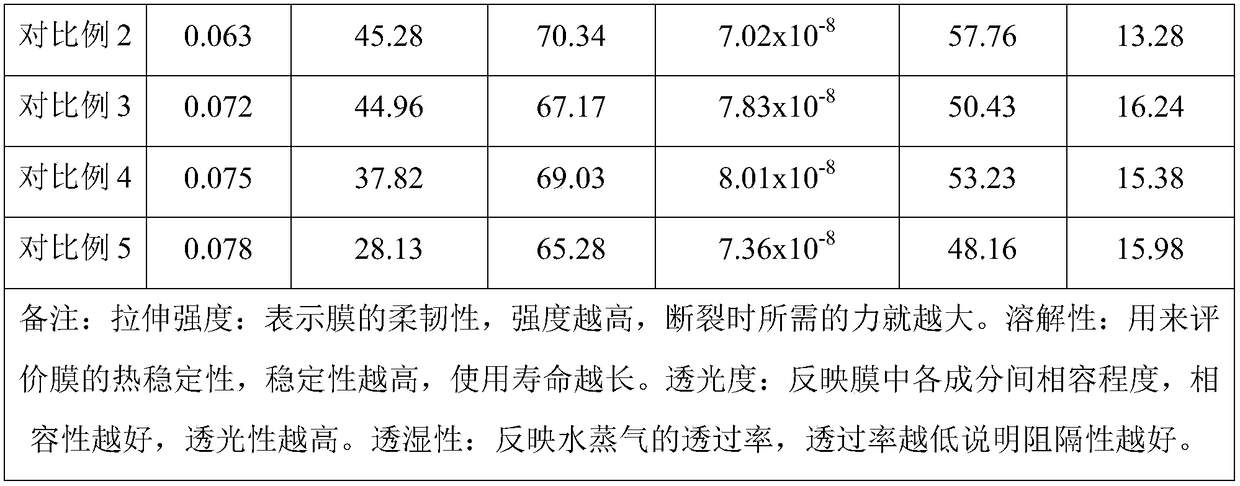

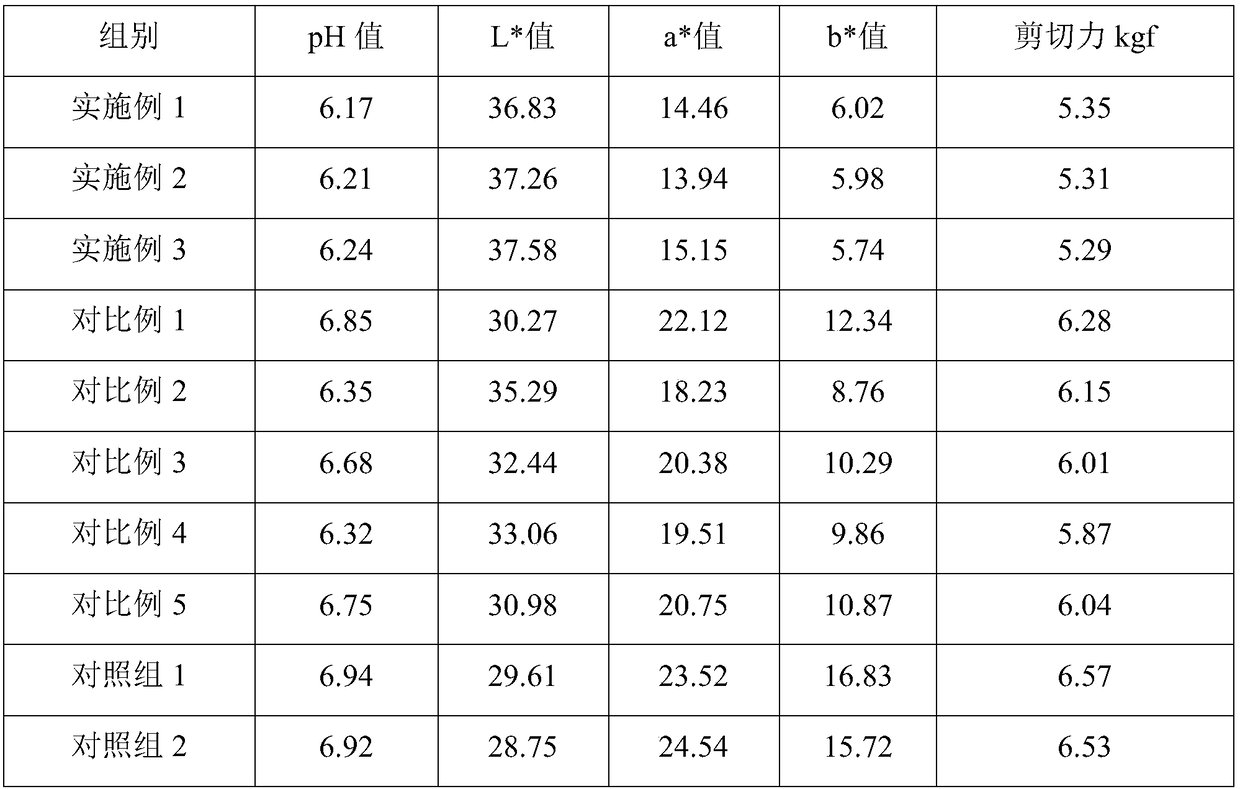

Examples

Embodiment 1

[0031] The method for improving the color and luster and tenderness of DFD meat comprises the following steps:

[0032] Step 1. Dissolving the flax protein isolate into an acidulant to make a film, wherein the acidulant is mainly composed of sodium chloride, potassium lactate, rosemary extract, glucono-δ-lactone, purified water, and lactic acid The resulting mixture;

[0033] Step 2: Wrap the DFD meat with a film and refrigerate. The DFD meat is beef meat with pH=5.80, the thickness of the meat is 6cm, the refrigeration temperature is 4°C, and the refrigeration time is 72h;

[0034] The preparation method of the acidulant in step 1 is as follows in parts by weight: 0.2 parts of sodium chloride, 2 parts of potassium lactate, 0.1 part of rosemary extract, and 0.3 part of glucono-δ-lactone and stir evenly to obtain a mixture , adding a mass fraction of 0.3% lactic acid aqueous solution to adjust the pH value of the mixture to 4, then adding purified water to make the overall mas...

Embodiment 2

[0041] The method for improving the color and luster and tenderness of DFD meat comprises the following steps:

[0042] Step 1. Dissolving the flax protein isolate into an acidulant to make a film, wherein the acidulant is mainly composed of sodium chloride, potassium lactate, rosemary extract, glucono-δ-lactone, purified water, and lactic acid The resulting mixture;

[0043] Step 2: Wrap the DFD meat with a film and refrigerate. The DFD meat is beef meat, and the pH=6.80 meat thickness is 9cm, the refrigeration temperature is 4°C, and the refrigeration time is 72h;

[0044] The preparation method of the acidulant in step 1 is as follows in parts by weight: 0.4 part of sodium chloride, 3 parts of potassium lactate, 0.3 part of rosemary extract, and 0.5 part of glucono-δ-lactone and stir evenly to obtain the mixture , adding a mass fraction of 0.45% lactic acid aqueous solution to adjust the pH value of the mixture to 5, then adding purified water to make the overall mass 100 pa...

Embodiment 3

[0051] The method for improving the color and luster and tenderness of DFD meat comprises the following steps:

[0052] Step 1. Dissolving the flax protein isolate into an acidulant to make a film, wherein the acidulant is mainly composed of sodium chloride, potassium lactate, rosemary extract, glucono-δ-lactone, purified water, and lactic acid The resulting mixture;

[0053] Step 2: Wrap the DFD meat with a film and refrigerate. The DFD meat is a beef block, and the pH=6.40. The thickness of the meat block is 7.5cm.

[0054] The preparation method of the acidulant in step 1 is as follows in parts by weight: 0.3 part of sodium chloride, 2.5 parts of potassium lactate, 0.2 part of rosemary extract, and 0.35 part of glucono-δ-lactone and stir evenly to obtain the mixture , adding a mass fraction of 0.4% lactic acid aqueous solution to adjust the pH value of the mixture to 4.5, then adding purified water to make the overall mass 100 parts, stirring evenly, the overall mass is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com