Flue gas desulfurization and denitration system and method

A technology for desulfurization, denitrification and desulfurization systems, applied in the field of flue gas desulfurization and denitrification systems, can solve problems such as difficulty in popularization, poor desulfurization and denitrification effects, etc., and achieve the effects of wide application range, good adjustment characteristics, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

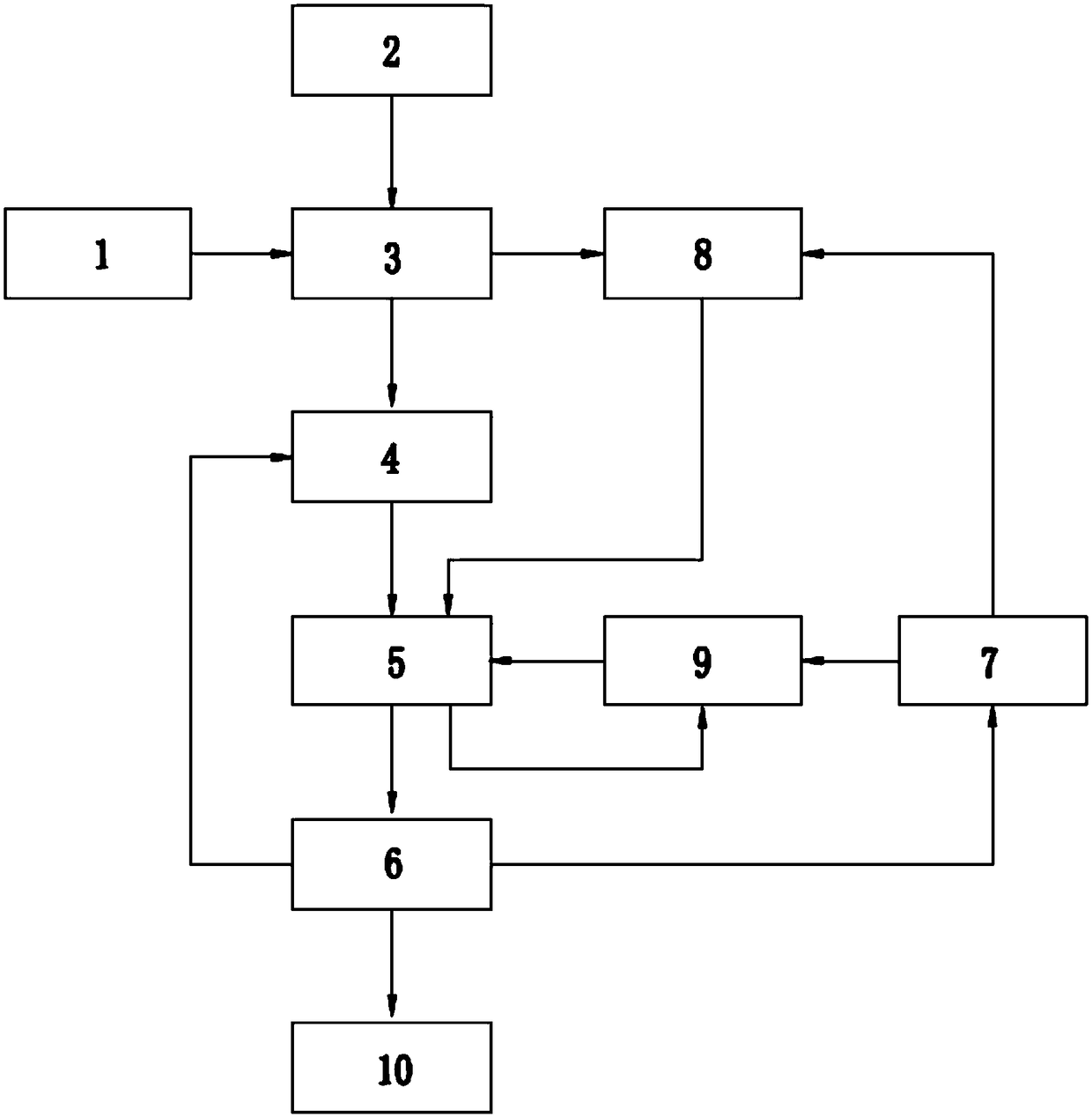

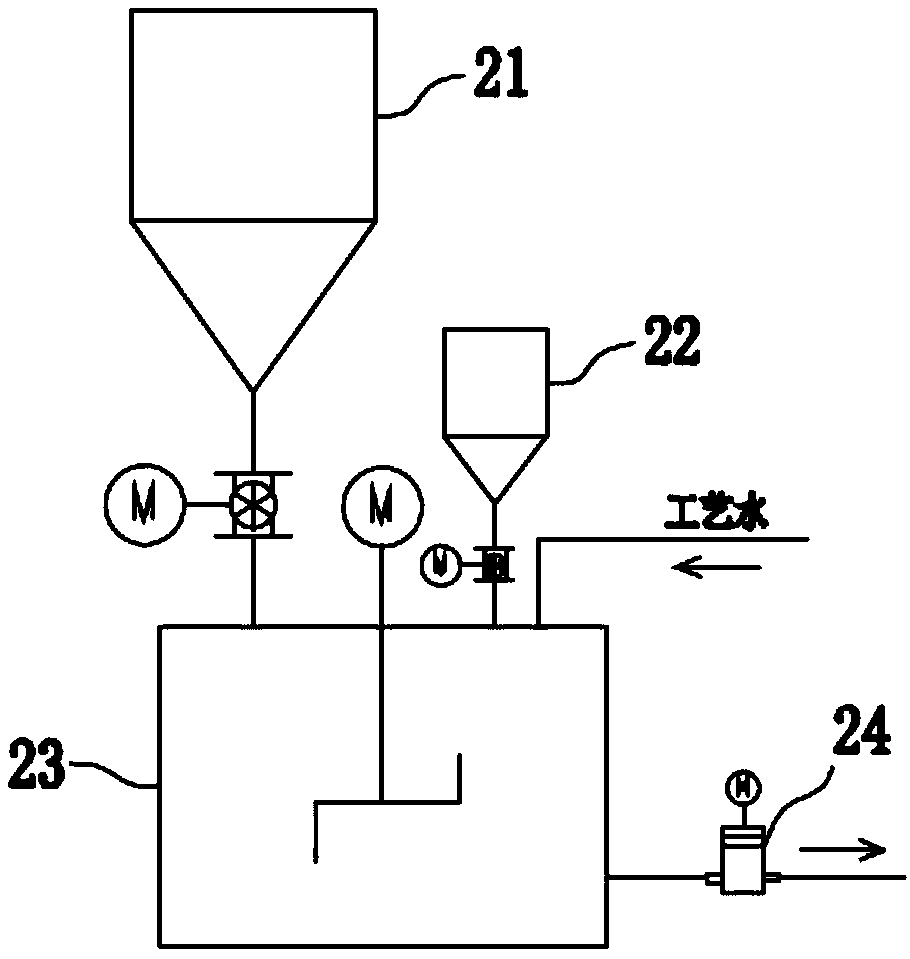

[0069] Such as figure 1 As shown, a flue gas desulfurization and denitrification system includes a pre-dust collector 1, a rotary spray desulfurization and denitrification system 3, an induced draft fan 6 and a chimney 10 arranged in sequence, the pre-dust collector 1, the rotary spray desulfurization and denitrification system 3, and an induced draft fan 6 and the chimney 10 are connected sequentially through the flue, and the rotary spray desulfurization and denitrification system 3 is used for preliminary desulfurization and denitrification of flue gas, wherein SO 2 Partially removed, NOx is oxidized to high-valence NO 2 and N 2 o 5A circulating fluidized bed desulfurization system 5 is arranged between the rotary spray desulfurization and denitrification system 3 and the induced draft fan 6, and is communicated in sequence through the flue, and most of the unreacted slaked lime in the rotary spray desulfurization and denitrification system 3 The powder enters the circul...

Embodiment 2

[0078] A flue gas desulfurization and denitrification system of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are that:

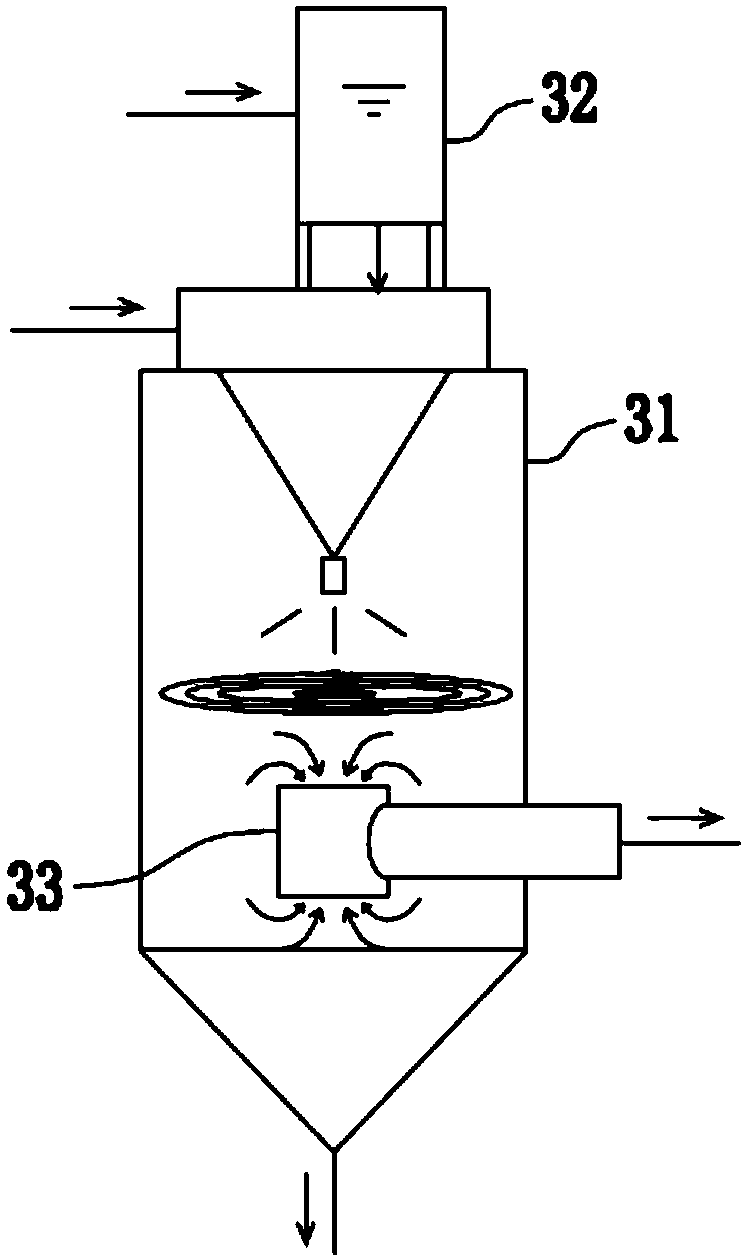

[0079] Such as image 3 As shown, the rotary spray desulfurization and denitrification system 3 includes a rotary spray desulfurization and denitrification reaction tower 31 and a self-flowing high-level emulsion tank 32, and the self-flowing high-level emulsion tank 32 is arranged above the top of the rotary spraying desulfurization and denitrification reaction tower 31. The forced oxidized milk of slaked lime in the self-flowing high-level emulsion tank 32 flows into the high-speed centrifugal atomizer in the rotary spray desulfurization and denitrification reaction tower 31 through the artesian tube arranged at the bottom of the self-flowing high-level emulsion tank 32 by gravity, Participate in the oxidation reaction in the rotary spray desulfurization and denitrification reaction tower 31 after a...

Embodiment 3

[0085] Such as image 3 As shown, a flue gas desulfurization and denitrification system of this embodiment has the same basic structure as that of Embodiment 2. The difference and improvement is that, further, the middle part of the bottom of the rotary spray desulfurization and denitrification reaction tower 31 is provided with shafts on both sides. To the exhaust device 33, the axial exhaust device 33 on both sides is a T-shaped structure formed by connecting and fixing two steel pipes at 90° to each other, and one of the two steel pipes is vertical One is set vertically, the other is set horizontally, the smoke enters from both ends of the vertically set steel pipe, and then is discharged from the horizontally set steel pipe; , will not affect the swirling air flow in the rotary spray desulfurization and denitrification reaction tower 31, which solves the problem of bias flow in the rotary spray desulfurization and denitrification reaction tower 31, and can prolong the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com