Method for preparing pyrochlore structure Bi2Ti2O7 ceramic by means of solid-phase reaction approach

A solid-phase reaction method and a pyrochlore technology are applied in the field of preparing pyrochlore structure Bi2Ti2O7 ceramics by a solid-phase reaction method, which can solve the problems of complicated operation and low output, and achieve the effects of simple reaction process, low cost and low requirements for reaction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

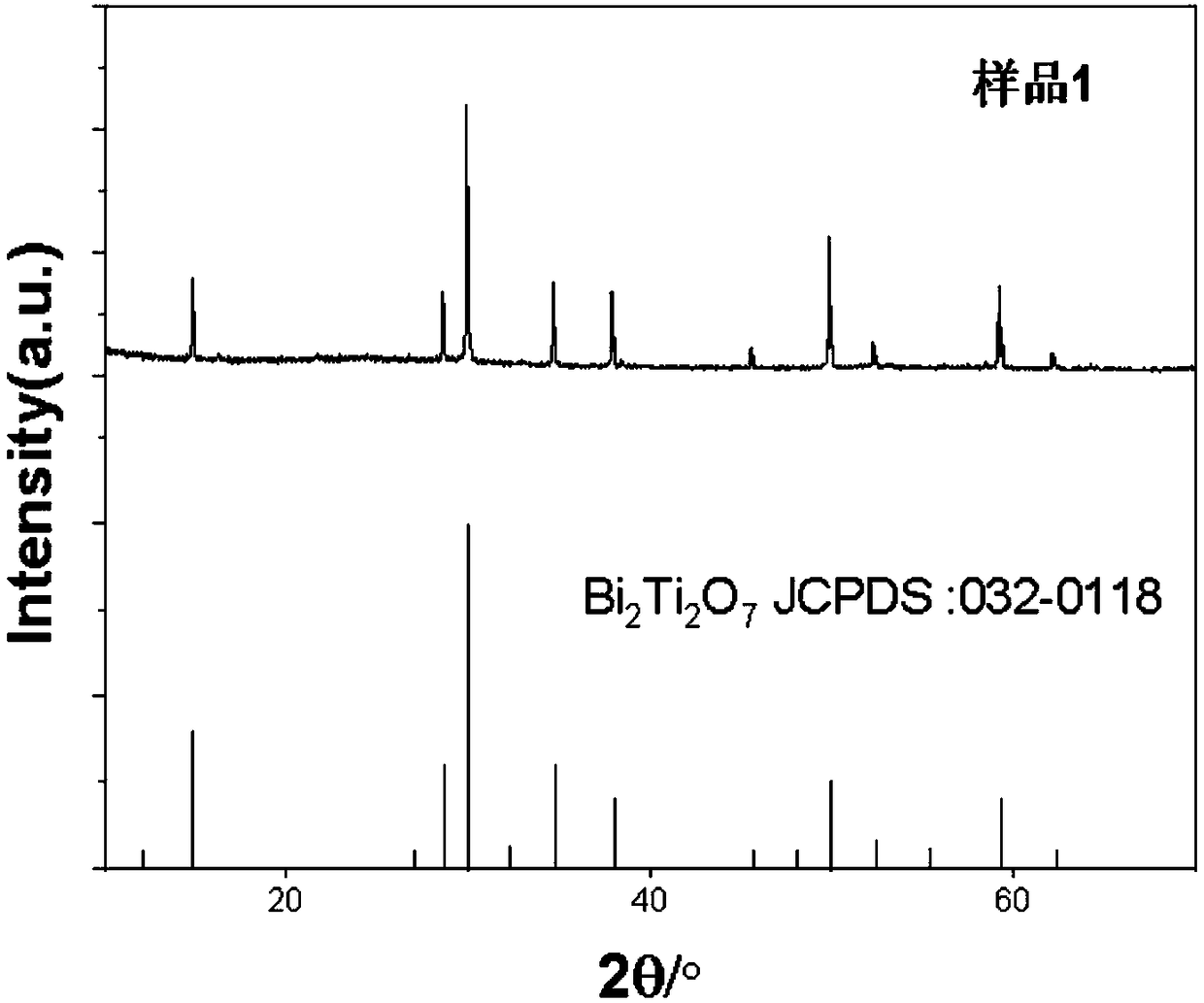

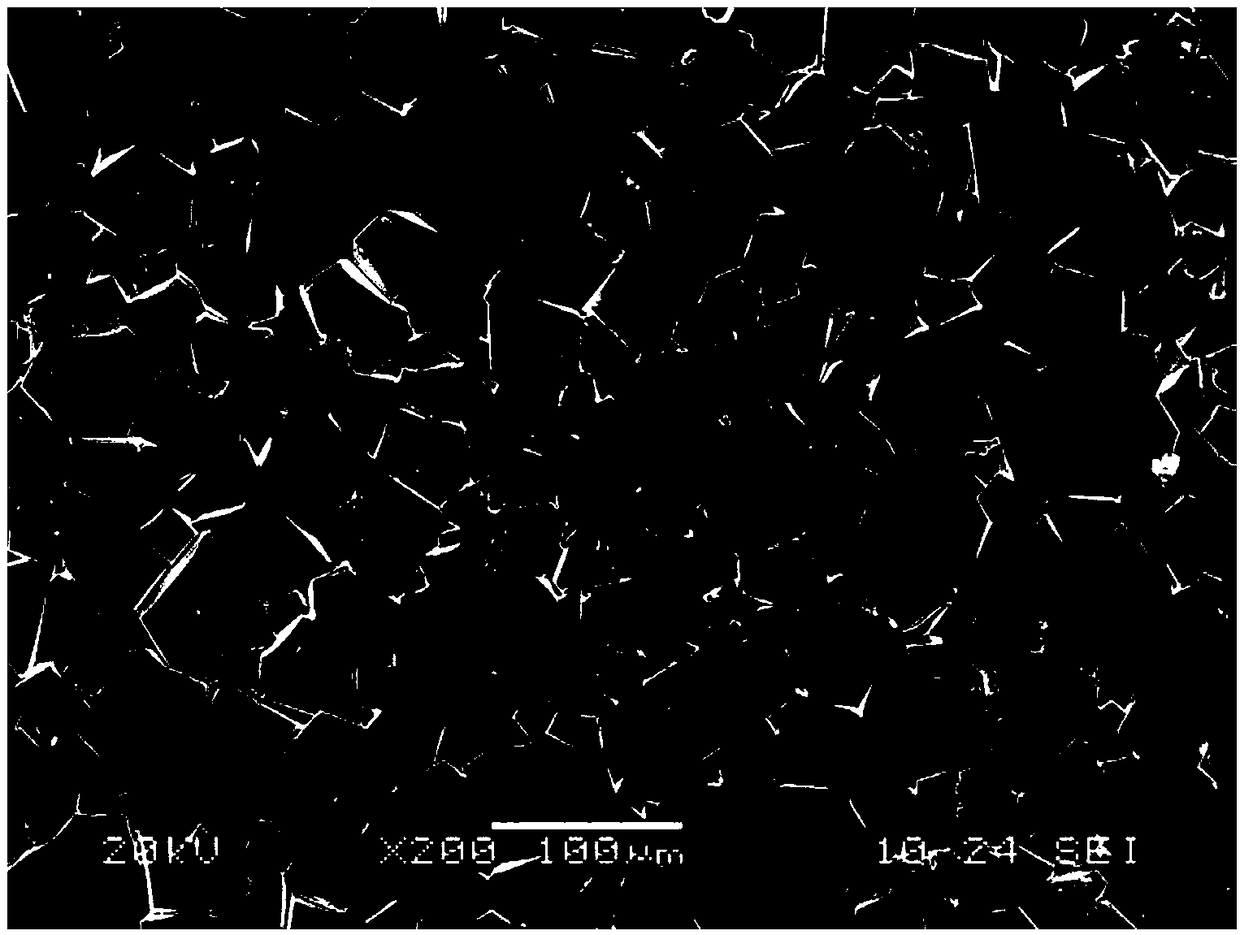

Embodiment 1

[0027] Preparation of Bi by solid state reaction method 2 Ti 2 o 7 The preparation method of ceramics, concrete preparation steps are as follows:

[0028] 1) Weigh 1.4345gBi 2 o 3 In the mortar, weigh 0.5655g TiO 2 into the mortar; adding absolute ethanol for grinding, after grinding three times, put it in a drying oven to dry overnight, and the drying temperature is 120°C;

[0029] 2) Put the dried mixture powder in a clean crucible, and then put it into a muffle furnace for pre-burning, the pre-burning temperature is 750°C, and the pre-burning time is 6 hours;

[0030] 3) Put the pre-calcined product in an agate mortar, add an appropriate amount of absolute ethanol and a small amount of PVA solution, grind it thoroughly to make it evenly mixed, then put it in a drying oven to dry overnight, and the drying temperature is 120°C;

[0031] 4) Put the dried mixture in step 3) into a mold of a tablet machine for dry pressing, slowly pressurize to 224MPa, and hold the pressur...

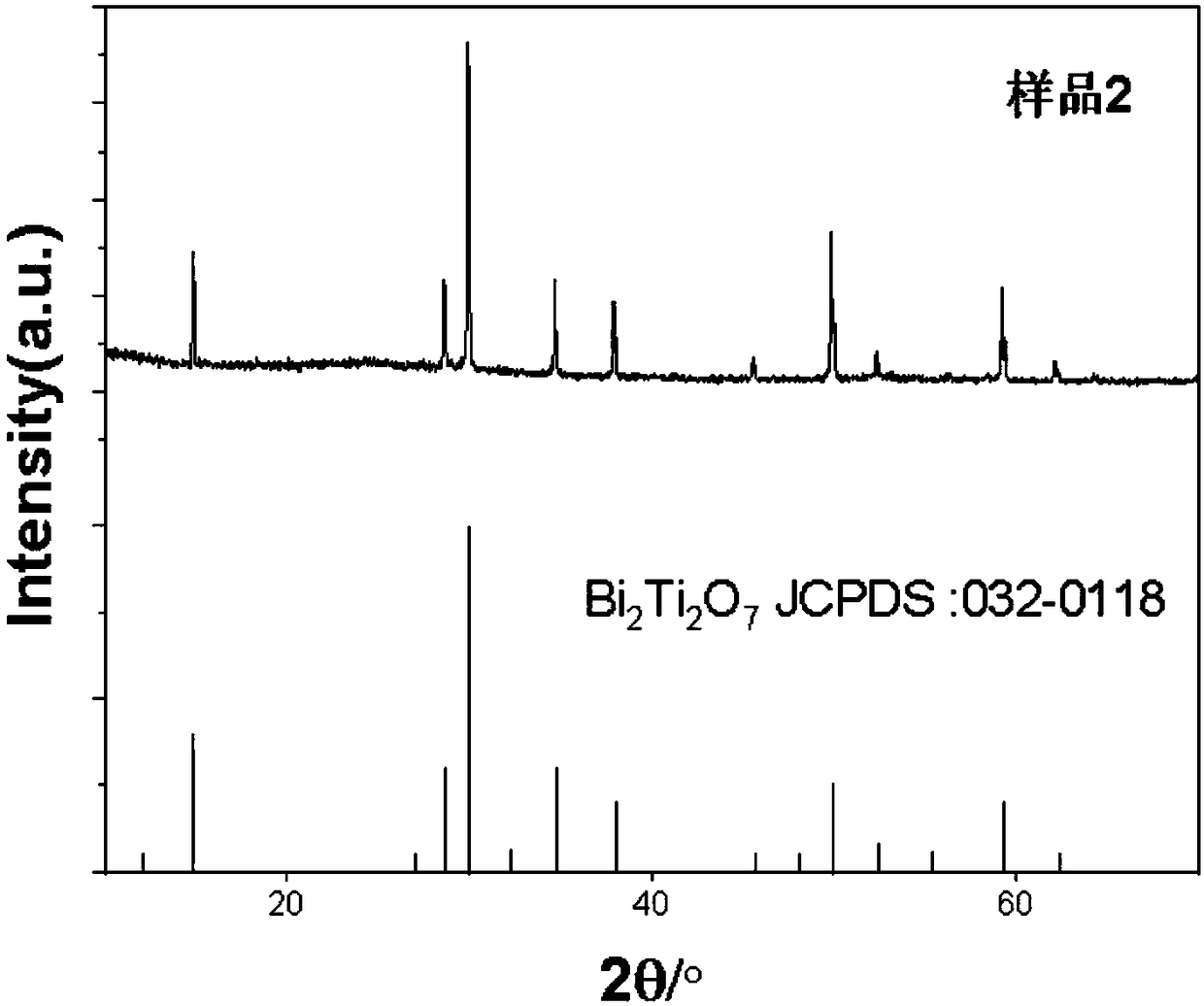

Embodiment 2

[0035] Preparation of Bi by solid state reaction method 2 Ti 2 o 7 The preparation method of ceramics, concrete preparation steps are as follows:

[0036] 1) Weigh 1.424gBi 2 o3 In the mortar, weigh 0.576g TiO accordingly 2 into the mortar; adding absolute ethanol for grinding, after grinding three times, put it in a drying oven to dry overnight, and the drying temperature is 120°C;

[0037] 2) Put the dried mixture powder in a clean crucible, and then put it into a muffle furnace for pre-burning, the pre-burning temperature is 800°C, and the pre-burning time is 6 hours;

[0038] 3) Put the pre-calcined product in an agate mortar, add an appropriate amount of absolute ethanol and a small amount of PVA solution, grind it thoroughly to make it evenly mixed, then put it in a drying oven to dry overnight, and the drying temperature is 120°C;

[0039] 4) Put the dried mixture in step 3) into a tablet machine mold for dry pressing, slowly pressurize to 224MPa, hold the pressure...

Embodiment 3

[0042] Preparation of Bi by solid state reaction method 2 Ti 2 o 7 The preparation method of ceramics, concrete preparation steps are as follows:

[0043] 1) Weigh 1.4171gBi 2 o 3 In the mortar, weigh 0.5829g TiO accordingly 2 into the mortar. Add anhydrous ethanol for grinding, grind three times and put it in a drying oven to dry overnight at a drying temperature of 120°C;

[0044] 2) Put the dried mixture powder in a clean crucible, and then put it into a muffle furnace for pre-burning, the pre-burning temperature is 800°C, and the pre-burning time is 6 hours;

[0045] 3) Put the pre-calcined product in an agate mortar, add an appropriate amount of absolute ethanol and a small amount of PVA solution, grind it thoroughly to make it evenly mixed, then put it in a drying oven to dry overnight, and the drying temperature is 120°C;

[0046] 4) Put the dried mixture in step 3) into a tablet machine mold for dry pressing, slowly pressurize to 224MPa, hold the pressure for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com