Method and system for extracting and separating CO2-C2H6 azeotrope from associated gas

A CO2-C2H6, separation method technology, applied in separation methods, hydrocarbon purification/separation, distillation separation, etc., can solve problems such as low ethane recovery rate, low refrigeration temperature, and ethane products that cannot meet the purity requirements, and achieve Reduce energy consumption, reduce freezing temperature, and ensure safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

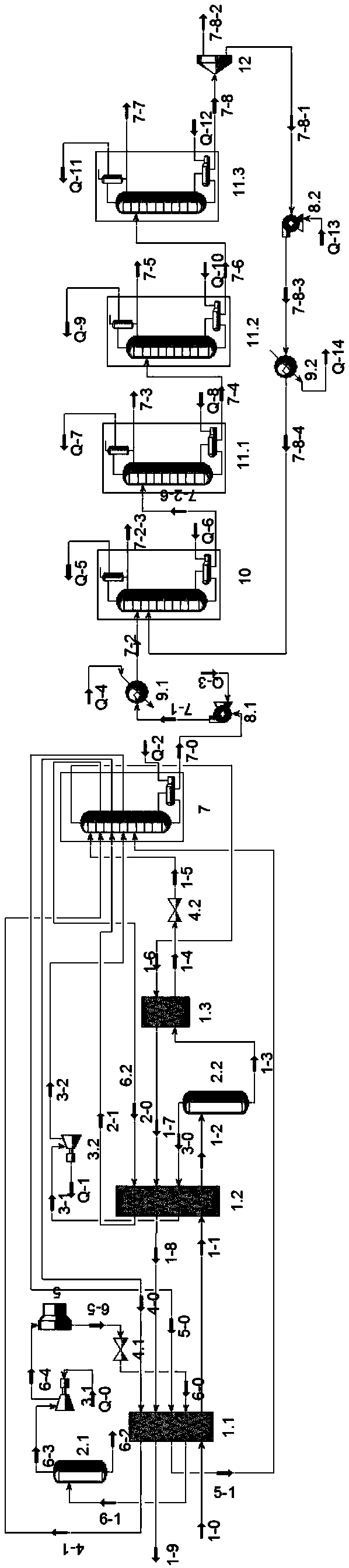

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

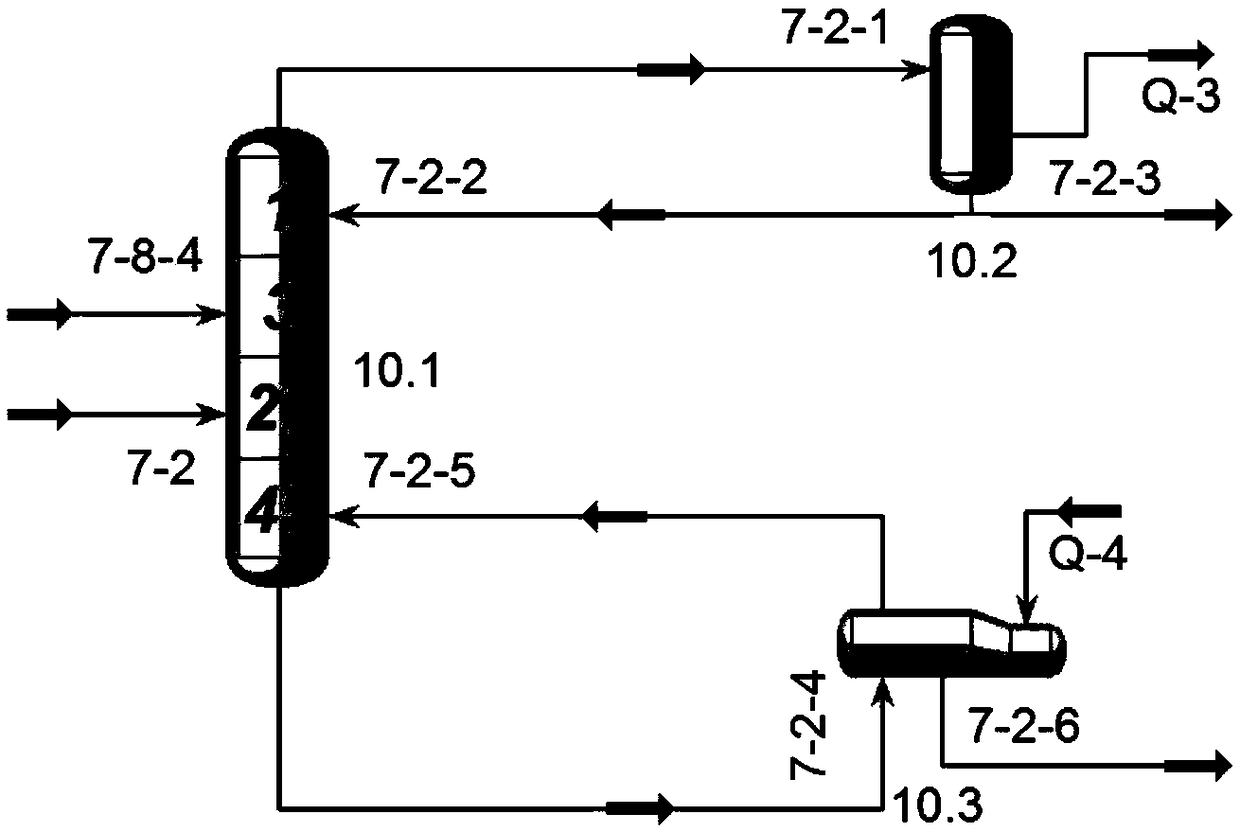

[0031] Such as figure 2 As shown, using CO in associated gas 2 -C 2 h 6 The system of the extraction and separation method of the azeotrope comprises an associated gas pretreatment device, the output end of the associated gas pretreatment device is connected to a demethanizer 7, and the top of the demethanizer 7 is provided with a methane outlet, and the demethanizer 7 The outlet at the bottom of the column is connected to the extractive distillation column 10 and then to the deethanizer 11.1.

[0032] The bottom output end of the demethanizer 7 is sequentially connected to the first centrifugal pump 8.1 and the first cooler 9.1 and then connected to the extractive distillation tower 10 .

[0033] The bottom output of the deethanizer 11.1 is connected to the depropanization rectification tower 11.2 and the debutanization rectification tower 11.3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com