Antibacterial fiber and preparation technology thereof

An antibacterial fiber and preparation technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of weakened antibacterial effect, water environmental pollution, easy shedding, etc., to achieve increased elasticity, anti-pilling performance and anti- The effect of electrostatic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

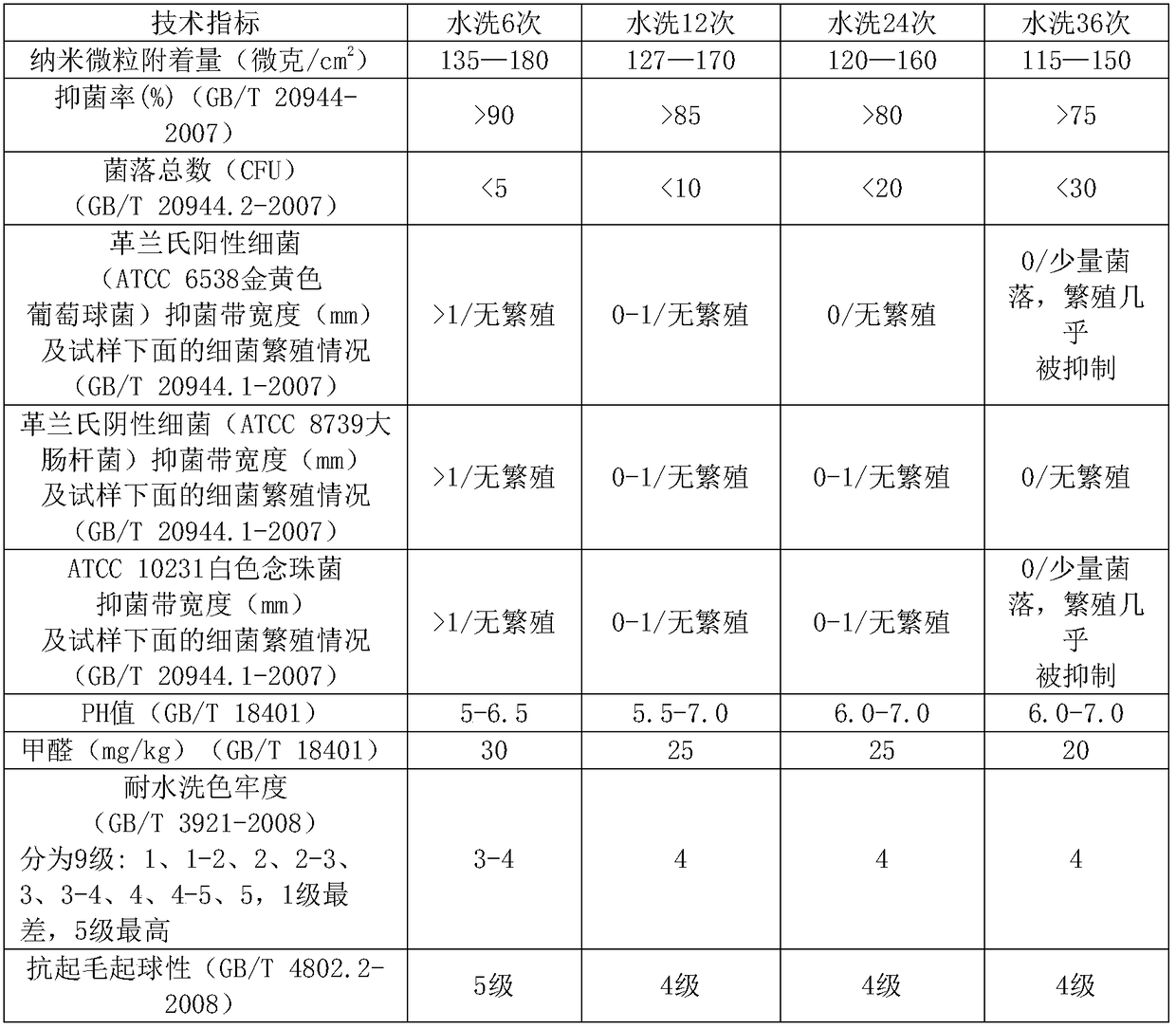

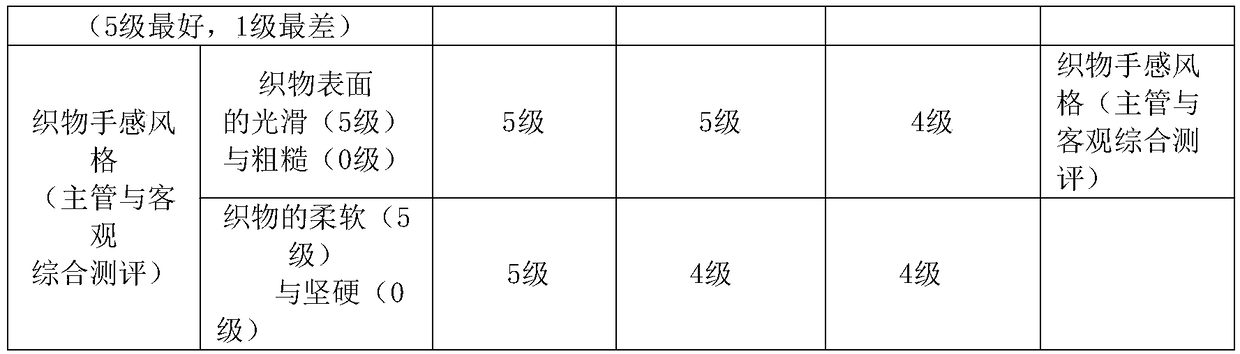

Examples

Embodiment 1

[0022] A kind of preparation technology of antibacterial cotton fiber, comprises the following steps:

[0023] a. Fiber pretreatment: place the cleaned cotton fiber in 5g / L sodium hydroxide solution, and treat it for 10 minutes at room temperature;

[0024] b. Prepare silver ammonia solution: Add ammonia water dropwise to 0.01mol / L silver nitrate solution until the initial precipitate is completely dissolved;

[0025] c. Adding nano PU microspheres: adding fibers to the silver ammonia solution configured in step b as nano PU microspheres with a length of no more than 100nm, so that the silver ammonia solution contains 3% nano PU microspheres with a mass fraction;

[0026] d, soaking fiber: immerse the cotton fiber treated in step a into the silver-ammonia solution containing nano-PU microspheres prepared in step c, stir and react for 24h, wherein the mass ratio of fiber to solution is 1:60;

[0027] e, drying for the first time: drying the cotton fiber processed in step d at ...

Embodiment 2

[0031] A kind of preparation technology of antibacterial hemp fiber, comprises the following steps:

[0032] a, fiber pretreatment: place the cleaned hemp fiber in 5g / L sodium hydroxide solution, and process it for 10min under normal temperature;

[0033] b. Configure silver ammonia solution: Add ammonia water dropwise to 0.03mol / L silver nitrate solution until the initial precipitate is completely dissolved;

[0034] c. Adding nano PU microspheres: adding fibers to the silver ammonia solution configured in step b as nano PU microspheres with a length of no more than 100nm, so that the silver ammonia solution contains 3% nano PU microspheres with a mass fraction;

[0035] d, impregnated fiber: immerse the processed hemp fiber of step a in the silver-ammonia solution that contains nano-PU microsphere that step c makes, stir, react 24h, wherein the mass ratio of fiber and solution is 1:60;

[0036] e, drying for the first time: drying the hemp fiber processed in step d at 60 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com