Cold exchange system and method for comprehensively utilizing cold energy of liquefied natural gas

A technology of liquefied natural gas and cold system, which is applied in the pipeline system, energy industry, indirect heat exchanger, etc., can solve the problems of cold pollution in the surrounding environment, waste of LNG cold energy, etc., to reduce the environmental hazards of low temperature, reduce carbon emissions, The effect of operating costs on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

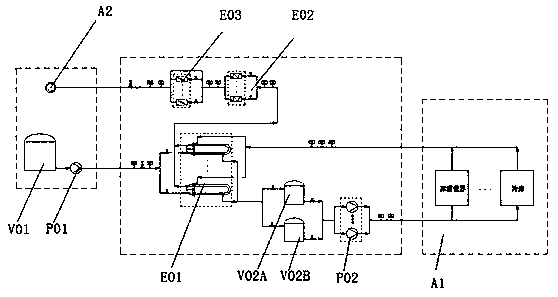

[0021] Such as figure 1 As shown, a cooling station system and device that comprehensively utilizes the cold energy of liquefied natural gas. The refrigerant absorbs the cooling capacity of LNG; the brine that has been cooled after heat exchange passes through the brine buffer tank and is boosted by the brine pump P02, and the pressurized brine enters the downstream and uses the cooling user A1 to provide cooling capacity for it; The brine that has been reheated by the cooling user A1 returns to the brine heat exchanger E01 and is recycled after being cooled; the natural gas that has exchanged heat with the brine enters the first natural gas thermostat E02 and the second natural gas temperature regulator in series. The thermostat E03 is reheated and sent to the natural gas pipeline network A2. When the supply of LNG cold energy is temporarily interrupted, the brine buffer tank can continue to supply brine for a period of time, so as to satisfy the downstream cold user A1 to s...

Embodiment 2

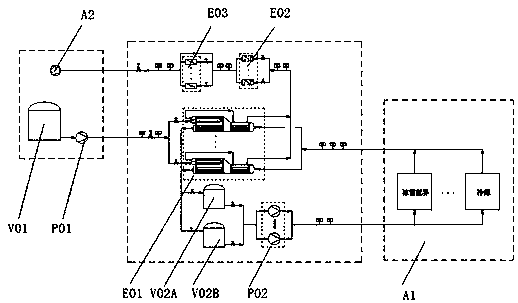

[0029] Such as figure 2 The difference from Example 1 is that the heat exchange process between the brine and LNG is a secondary heat exchange, and the secondary heat exchange means that the LNG first exchanges heat with the intermediate refrigerant, and then the intermediate refrigerant exchanges heat with the brine. hot. LNG first exchanges heat with the intermediate refrigerant in the refrigerant heat exchanger, and transfers the cold energy of LNG to the intermediate refrigerant; then the intermediate refrigerant exchanges heat with the refrigerant, and transfers the cold energy to the refrigerant. In this process, the LNG cold energy is transferred to the brine through two heat exchanges. The brine heat exchanger in the secondary heat exchange system is a three-channel shell-and-tube heat exchanger, in which the liquefied natural gas goes through the tube side, The intermediate refrigerant goes through the shell side, and the secondary refrigerant goes through the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com