Process for pressure purification of silicon trichlorohydrgen and apparatus thereof

A technology of trichlorosilane and a purification method, which is applied in the directions of halogenated silanes, halogenated silicon compounds, etc., can solve the problems of unreasonable technical parameters of trichlorosilane purification process, high operation and maintenance costs, and high energy consumption, and achieves Reduce equipment investment and equipment operating costs, the effect of high pressure and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

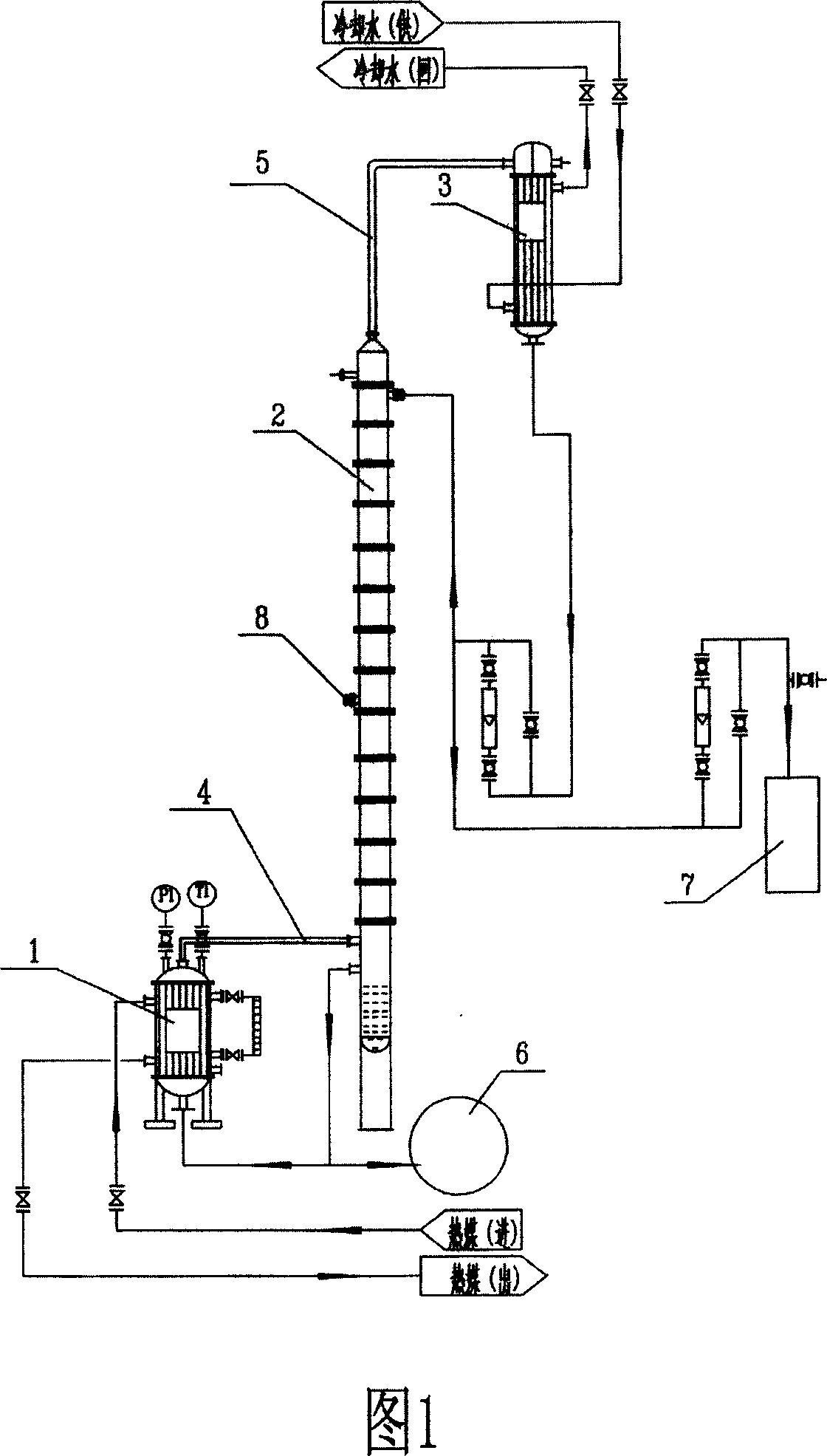

[0021] Embodiment Referring to Fig. 1, the distillation kettle 1 adopts a shell-and-tube heat exchanger suitable for distillation operation conditions, the operating pressure range of the equipment: 0.15Mpa-1.5Mpa, and the operating temperature range: 70-200°C. Heat the still 1 with heat medium such as steam, hot water or heat conduction oil to vaporize the distilled trichlorosilane and silicon tetrachloride liquids, and the vaporized steam enters the purification 2 through the connecting pipe 4 .

[0022] The inside of the purification tower 2 is a sieve plate structure, and the operating pressure range of the equipment is 0.15Mpa-1.5Mpa; the operating temperature range is 40-150°C. SiHCl from still 1 3 、SiCl 4 The mixed steam is exchanged and separated between heat and components on the sieve plates at all levels of the purification tower, and the components with low boiling points (SiHCl 3 ) is enriched in the vapor phase, components with high boiling points (SiCl 4 ) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com