Device and method for microleak identification of coal-powder boiler or circulating fluidized bedboiler

A technology of circulating fluidized bed and pulverized coal furnace, which is applied in the device field of automatic identification and alarming, and the device field of identifying the alarm when micro leakage occurs in pulverized coal furnace or circulating fluidized bed boiler. It is easy to analyze historical data, save time and cost, and reduce economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

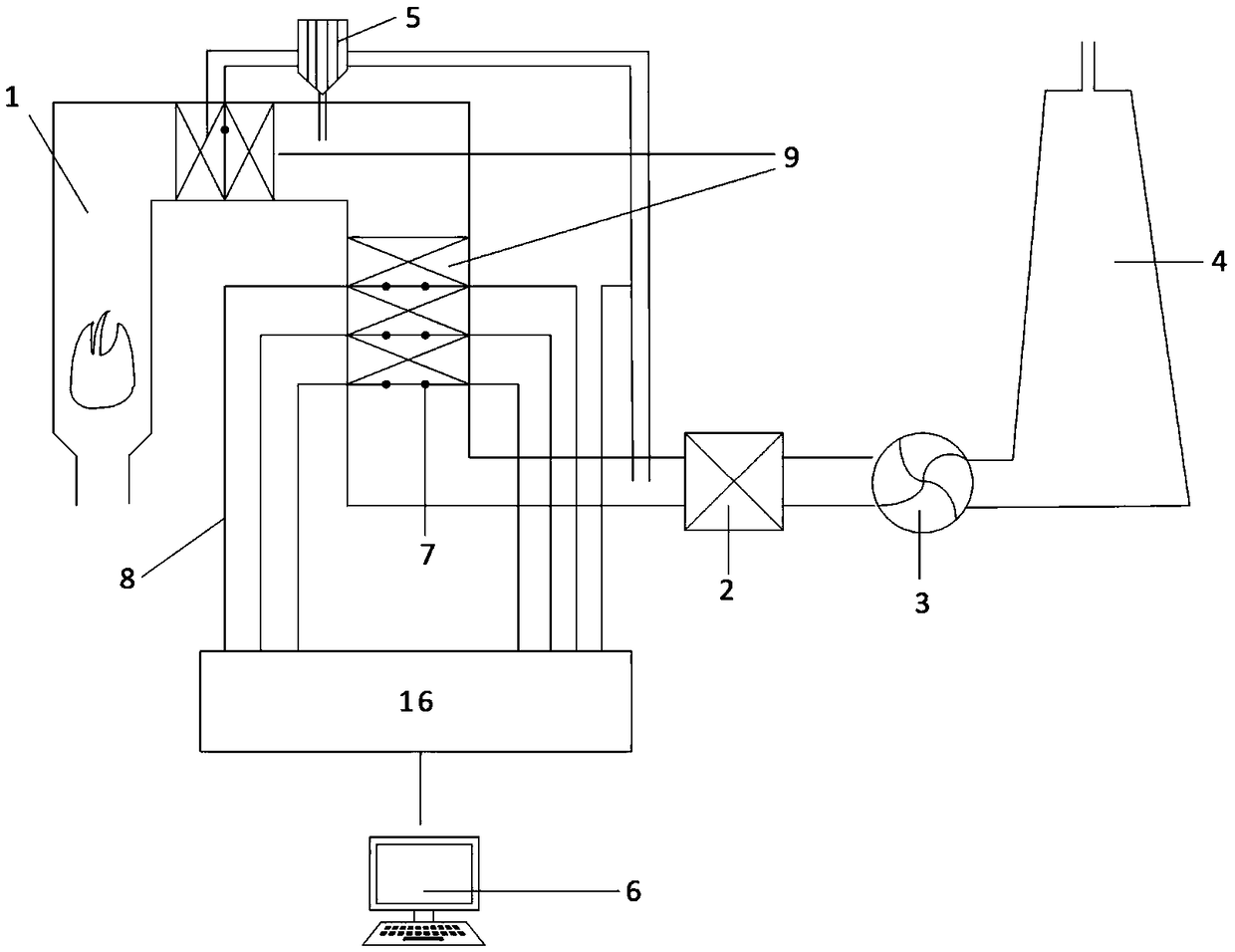

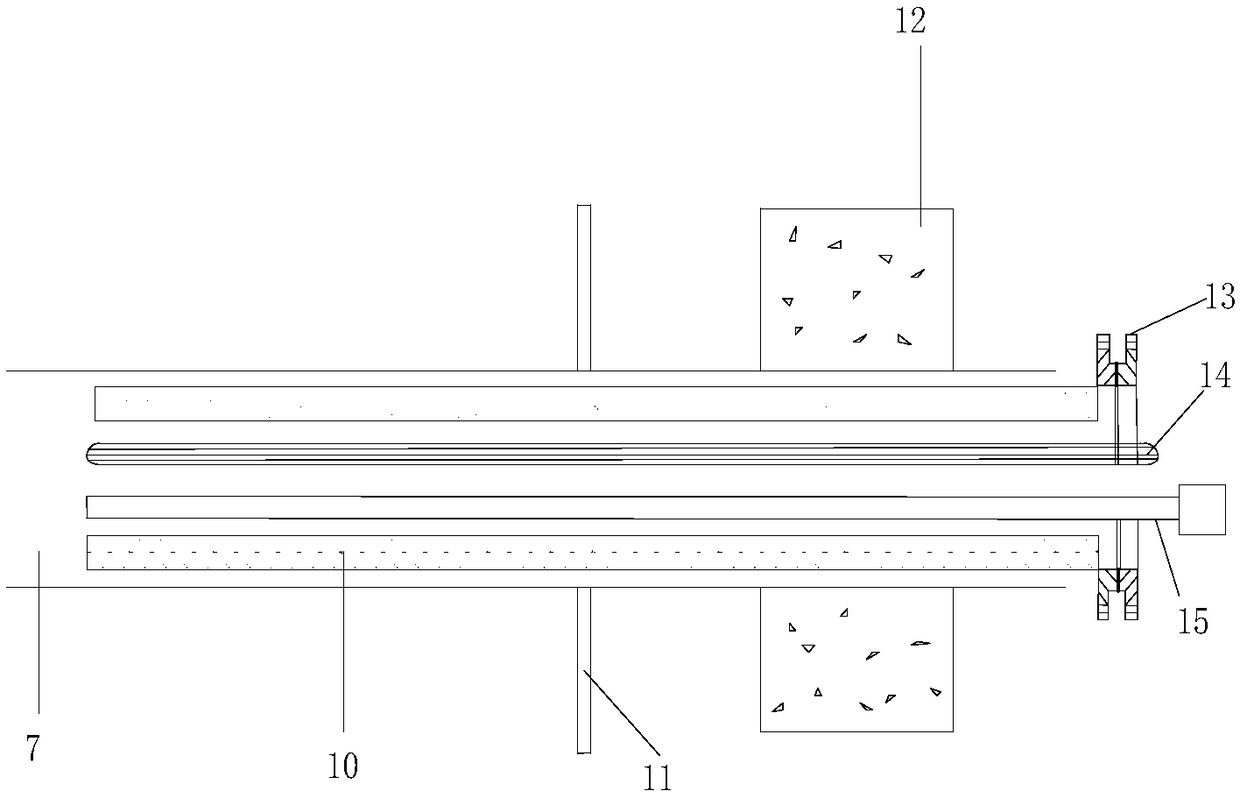

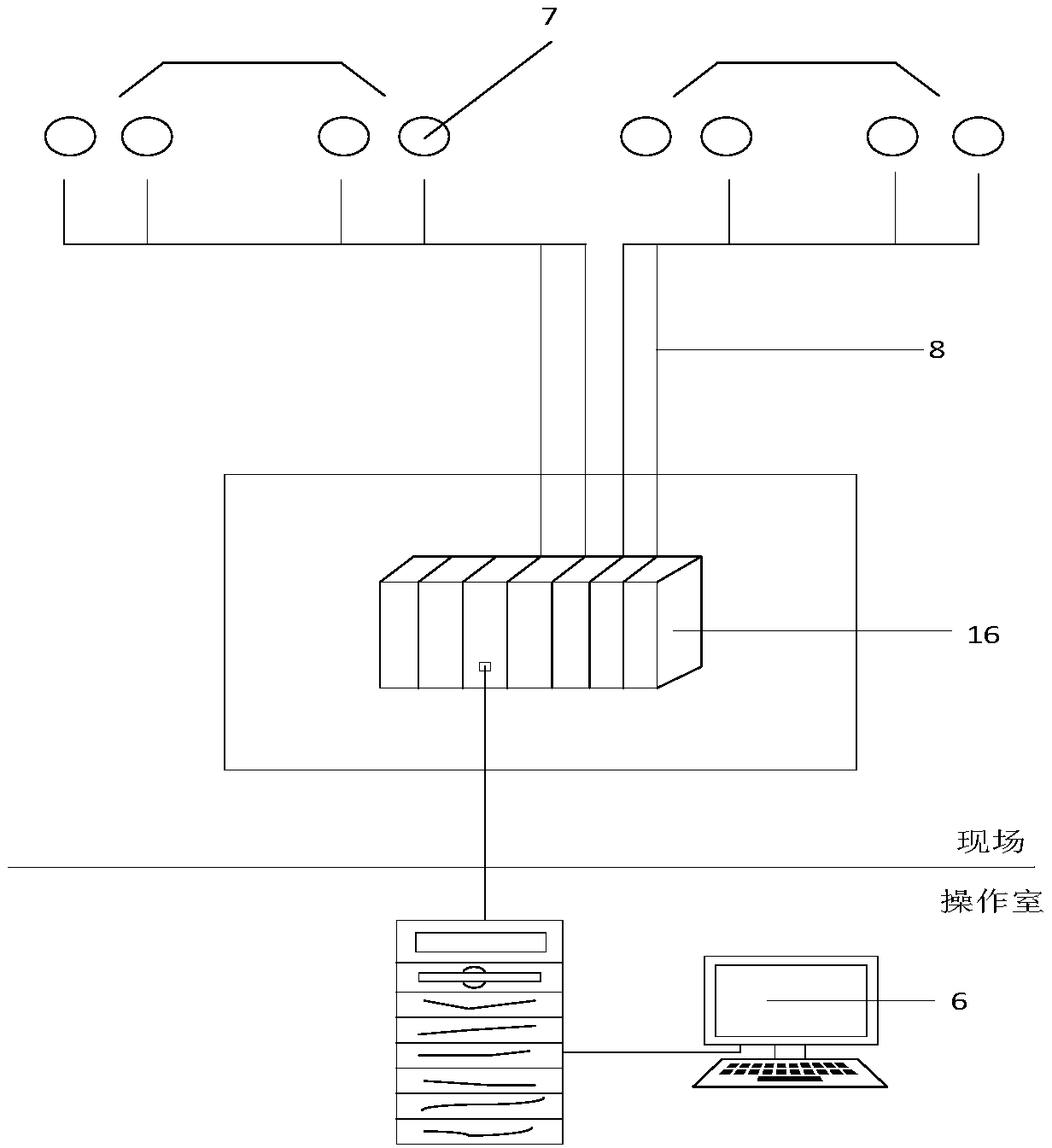

[0020] please see figure 1 , 2 and image 3 , a device for identifying micro-leakage of a pulverized coal furnace or a circulating fluidized bed boiler provided by the present invention includes a furnace flue 1, a dust collector 2, an induced draft fan 3, a chimney 4, a dust-proof device 5, a computer 6, and a Hole measuring point 7, cable 8, heating surface 9, thermocouple 14, hygrometer 15, PLC system 16. Select measuring points on both sides of the heating surface 9 in the furnace flue 1 and open holes. The opening measuring points 7 are distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com