Improved terahertz branch waveguide coupler

A branched waveguide and coupler technology, which is applied in the field of improved terahertz branched waveguide couplers, can solve the problems of narrow barrier structures that are prone to bending or even breaking, coupler stability and service life discount, and deterioration of coupler performance. Achieve the effects of strong and firm metal barrier structure, increase coupling coefficient, and reduce processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

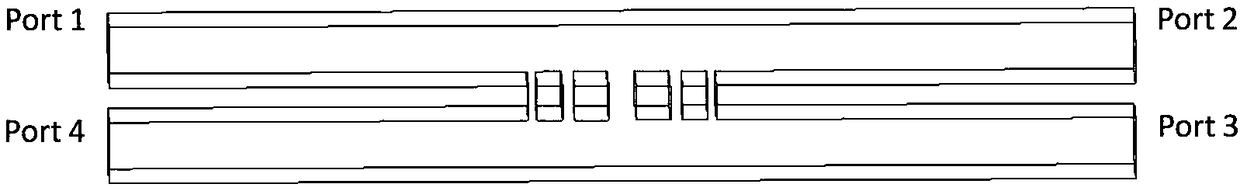

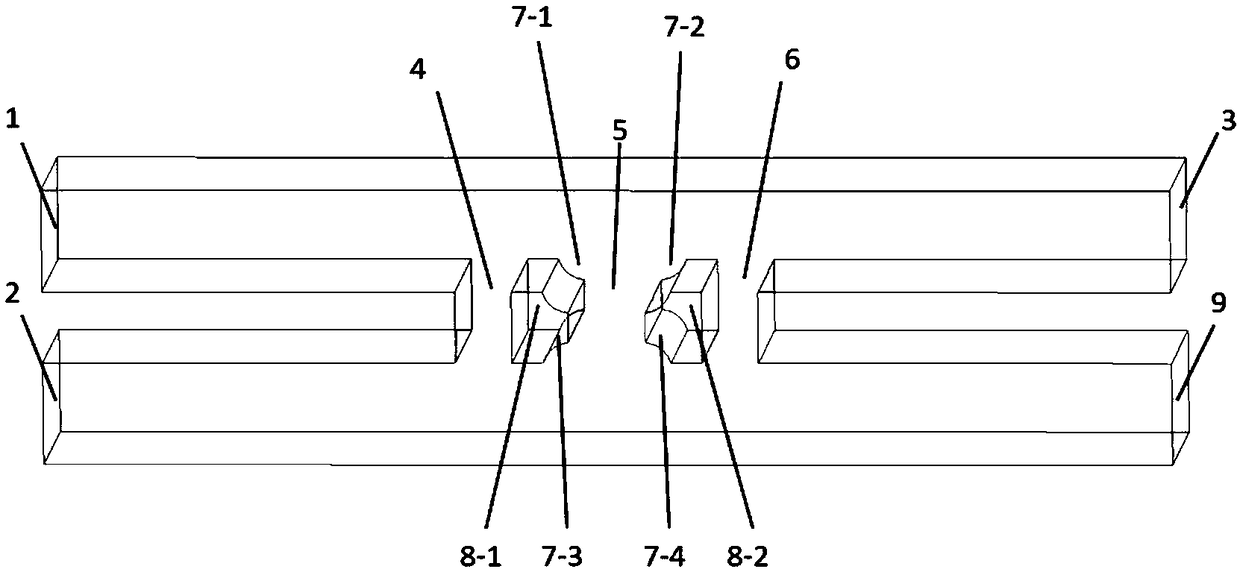

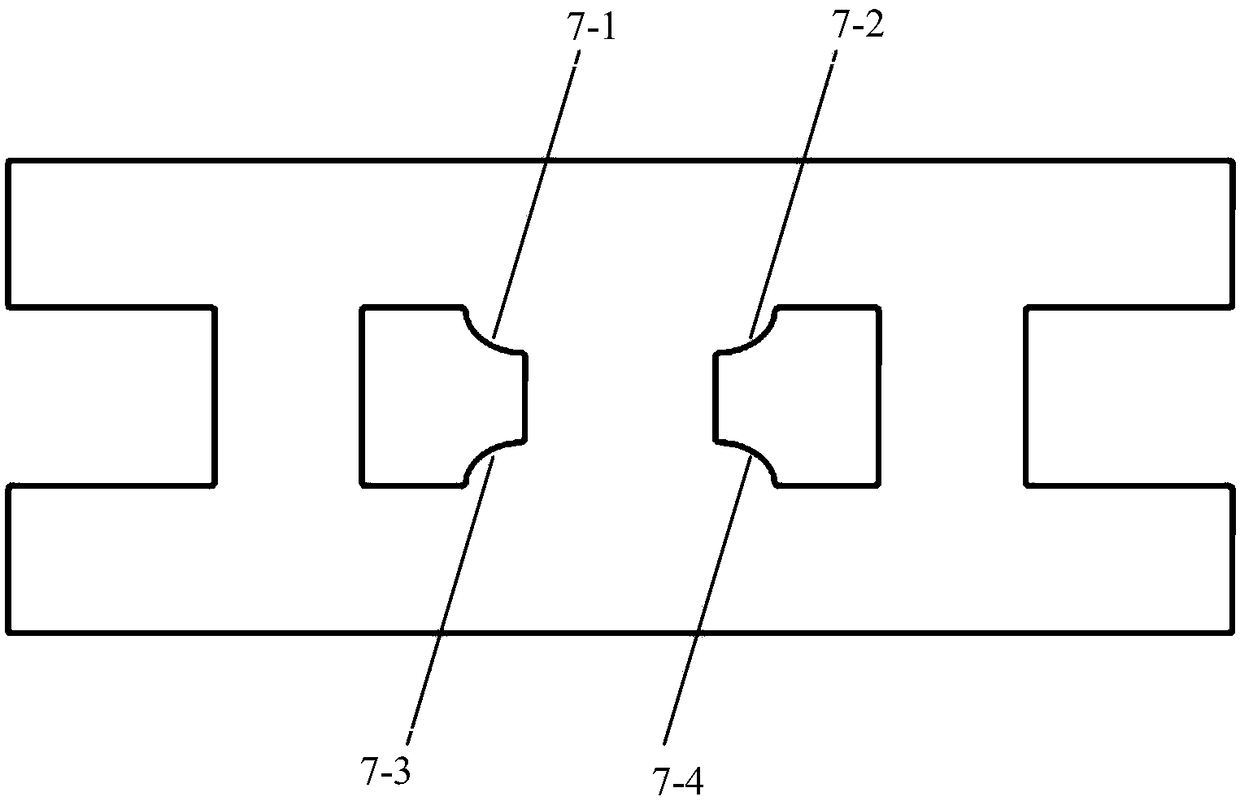

[0028] In a 3dB branch waveguide coupler provided in this embodiment, the cavity adopts a standard waveguide WR-4.3, the length of side a is 1.092 mm, the length of side b is 0.546 mm, and its transmission frequency is 170 GHz to 260 GHz; the first electromagnetic field channel The width of 4 is 0.3 mm, the width of the third electromagnetic field channel 6 is 0.3 mm; in the second electromagnetic field channel 5, the radius of the first, second, third, and fourth coupling fillets is 0.15 mm, and the rectangular cavity in the middle part The width is 0.38mm; the structure and parameter dimensions of the first metal grille 8-1 and the second metal grille 8-2 are as follows Figure 4 As shown, the radius R of the fillet formed in the first and second metal grilles is 0.15mm, the maximum thickness of the first and second metal grilles is 0.3mm, the length is 1.092mm, and the width is 0.38mm. Its aspect ratio is 1.27 (0.38mm / 0.3mm). The branch waveguide coupler is obtained by usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com