Switched reluctance motor with water-injected winding and multi-directional self-circulating ventilation system

A switched reluctance motor, self-circulation technology, applied in the direction of cooling/ventilation devices, electric components, electromechanical devices, etc., can solve the temperature increase of the stator core and stator copper windings, which threatens the safe and stable operation of large-capacity switched reluctance motors, and limits Increase the capacity of switched reluctance motors to achieve the effect of improving cooling capacity and density power, reducing temperature and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

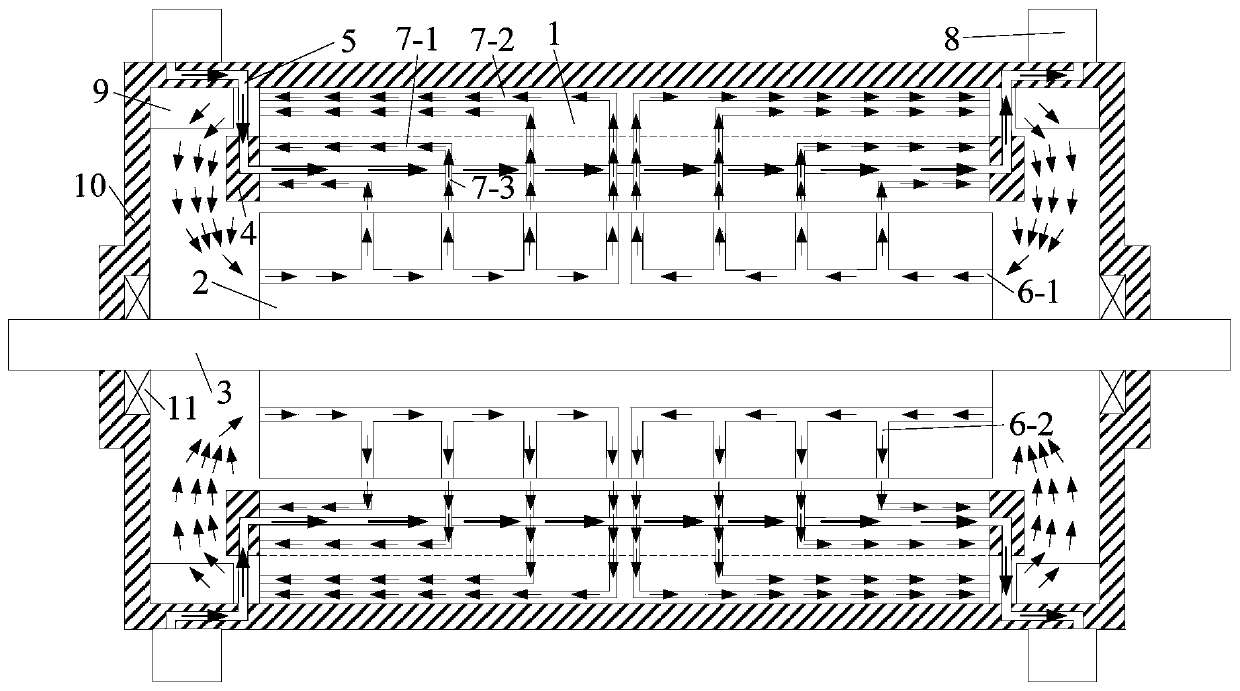

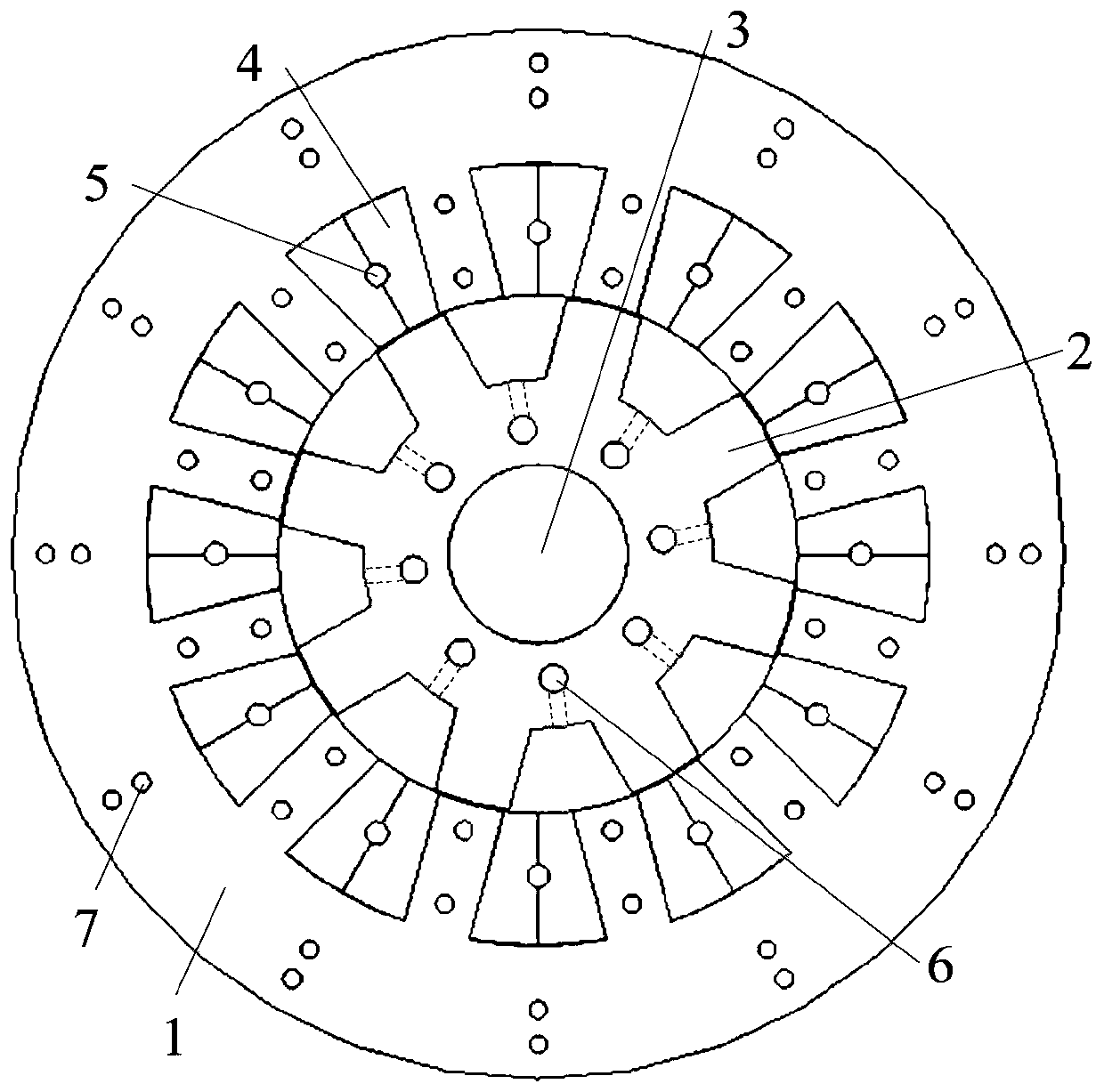

[0024] Specific implementation mode one, such as figure 1 and figure 2 As shown, the arrows in the figure show the flow direction of the cooling gas in the switched reluctance motor with water injection winding and multi-directional self-circulating ventilation system. The switched reluctance motor with water injection winding and multi-directional self-circulating ventilation system according to the present invention includes stator core 1, rotor core 2, rotor shaft 3, stator copper winding 4, stator direct cooling water pipe 5, and rotor direct cooling ventilation channel 6. Stator direct cooling air passage 7, stator direct cooling water drive device 8, sheet heat conduction plate 9, machine base 10 and bearing 11;

[0025] The rotor shaft 3 is installed on the base 10 through the bearing 11, the rotor core 2 is installed on the rotor shaft 3, the stator core 1 is installed on the inner wall of the base 10, the stator copper winding 4 is installed on the stator core 1, an...

specific Embodiment approach 2

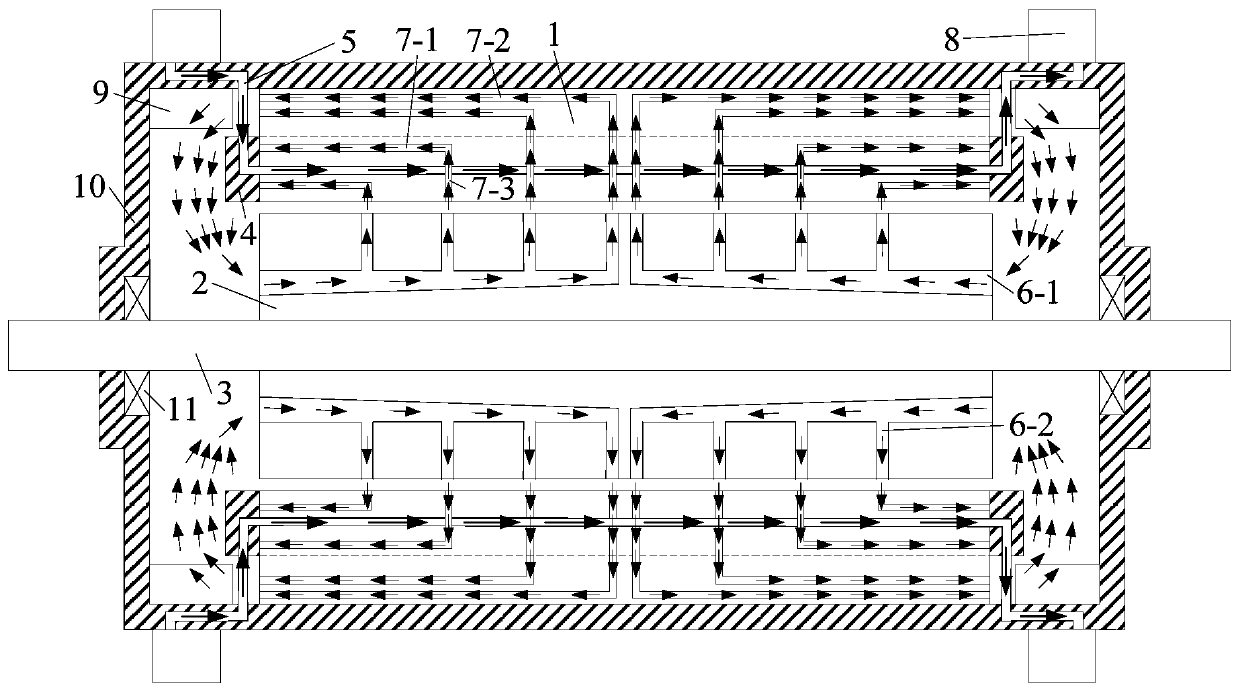

[0031] Specific implementation mode 2: Combining image 3 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the inlet area of the rotor axial direct cooling air passage 6-1 is increased, and the inlet area is 130 mm. 2 ~400mm 2 , the cross-sectional area of the rotor axial direct cooling air duct 6-1 gradually decreases along the axial direction, which can increase the fluid flow rate entering the rotor core 2, speed up the circulation speed of the cooling gas in the switched reluctance motor, and improve the cooling rate of the cooling gas. The utilization rate of the switched reluctance motor reduces the temperature of the stator core 1, rotor core 2 and stator copper winding 3 inside the switched reluctance motor. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific implementation three: combination Figure 4 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the number of stator direct cooling air passages 7 in the stator core 1 has been increased, the cooling effect of the yoke of the stator core 1 has been enhanced, and the internal temperature of the stator core 1 has been improved. The surface heat dissipation coefficient effectively improves the ability of the cooling gas to take away heat from the stator core 1 and further reduces the temperature of the stator core 1 . Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com