Regenerative lead-ammonium-method desulphurization and ammonium sulfate preparation process and device

A desulfurization equipment and ammonium sulfate technology are applied in the field of regenerated lead-ammonium desulfurization, which can solve the problems of high price, high consumption of fuel and auxiliary materials, etc., and achieve the effects of increasing concentration, good economic benefits, and reducing labor intensity and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

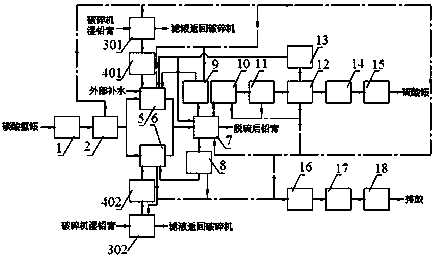

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, the present invention includes feeder 1, unpacking machine 2, lead paste filter press I 301 before desulfurization, lead paste filter press II 302 before desulfurization, dry lead paste conveyor I 401, dry lead paste conveyor II402, Primary desulfurization equipment 5, secondary desulfurization equipment 6, lead paste filter press after desulfurization 7, primary desulfurization filtrate storage tank 8, lead paste rinse liquid storage tank 9, secondary desulfurization filtrate storage tank 10, ammonium sulfate filtrate purification equipment 11, MVR crystallization drying equipment 12, distilled water storage tank 13, packaging equipment 14, palletizer 15, acid spray tower 16, lye spray tower 17, exhaust fan 18, the feeding machine 1 and unpacking machine 2 The feeding belt conveyor is connected; the discharge port of the unpacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com