Venturi jet mixing reactor, oleamide continuous synthesis apparatus and application method thereof

A technology of jet mixing and oleic acid amide, which is applied in chemical methods for reacting liquid and gaseous media, chemical/physical/physical chemical nozzle reactors, carboxylic acid amide preparation, etc., can solve environmental pollution and treatment costs high ammonia consumption and other problems, to achieve the effect of improving utilization rate, avoiding waste and pollution, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

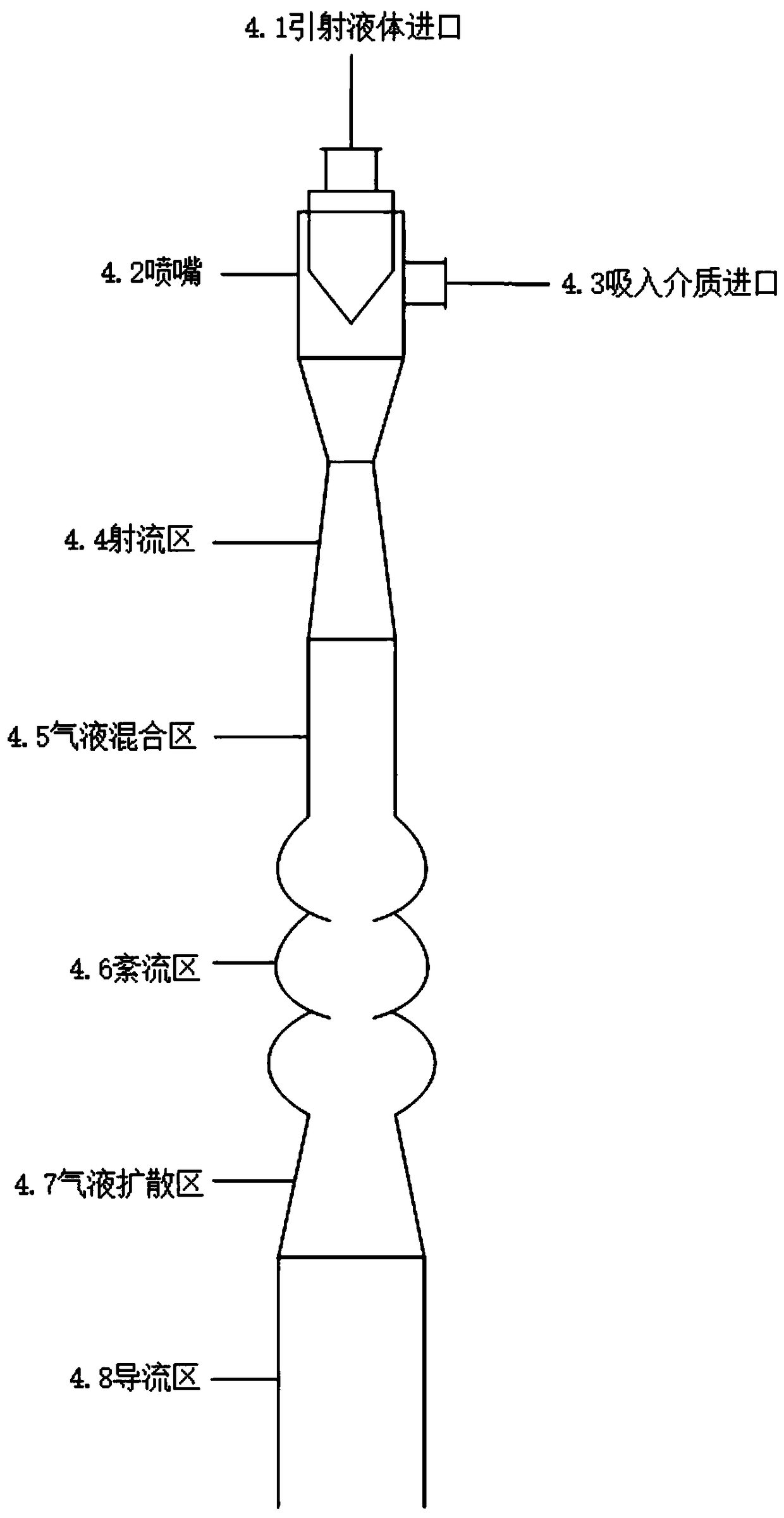

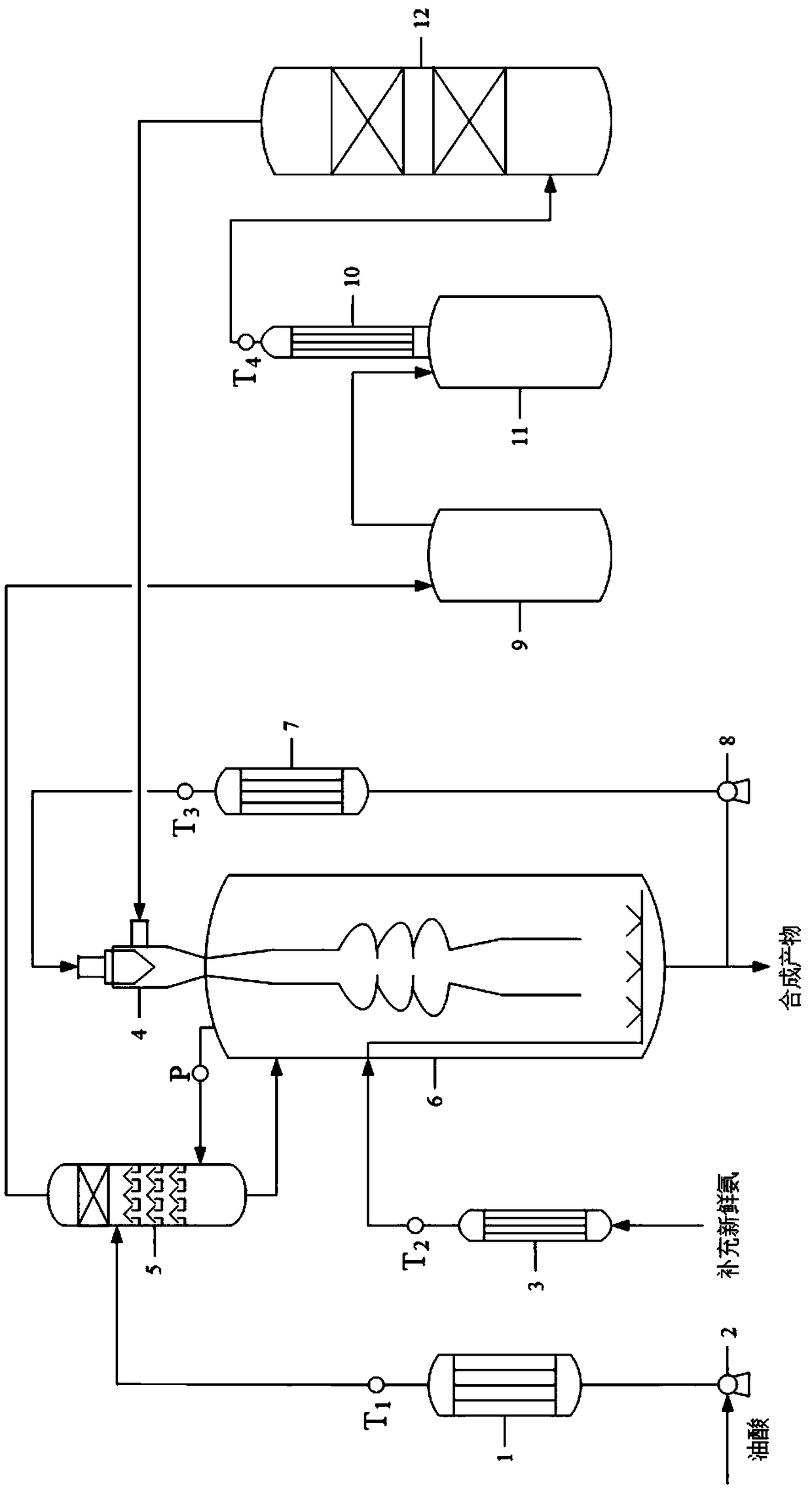

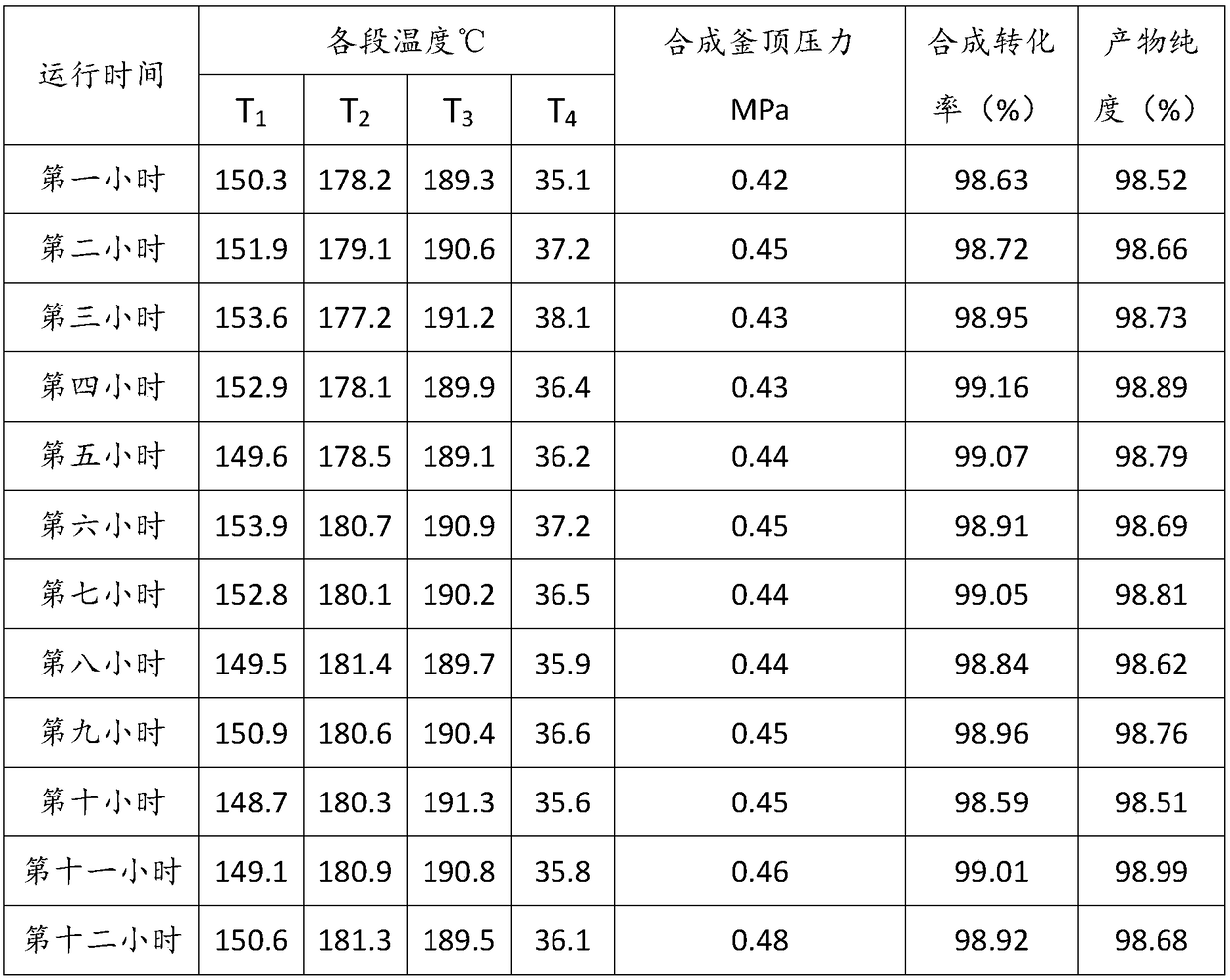

[0059] The raw material of oleic acid (the feed rate is 200kg / h) is preheated by the oleic acid preheater and enters the separation tower, where it exchanges heat with the tail gas entering the separation tower from the synthesis kettle; the raw material of oleic acid after the heat exchange It is discharged from the bottom of the separation tower and enters the synthesis kettle; the tail gas after heat exchange is discharged from the top of the separation tower, and after being treated by ammonia trap, gas-water separator, condenser and drying tower, pure and dry ammonia gas is obtained, and passed through Venturi The suction medium inlet of the jet mixing reactor enters the Venturi jet mixing reactor; the ammonia raw material (18kg / h) is preheated by the ammonia preheater and enters the synthesis kettle, where it is mixed with the oleic acid raw material Preliminary reaction, the mixture formed by the unreacted oleic acid raw material and the obtained preliminary reaction pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com