Solvent type acrylic pressure-sensitive adhesive and preparation method thereof

An acrylic pressure-sensitive adhesive, solvent-based technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems affecting the appearance of mobile phone screens, pollution, etc., to achieve mass production, high product quality, good quality The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

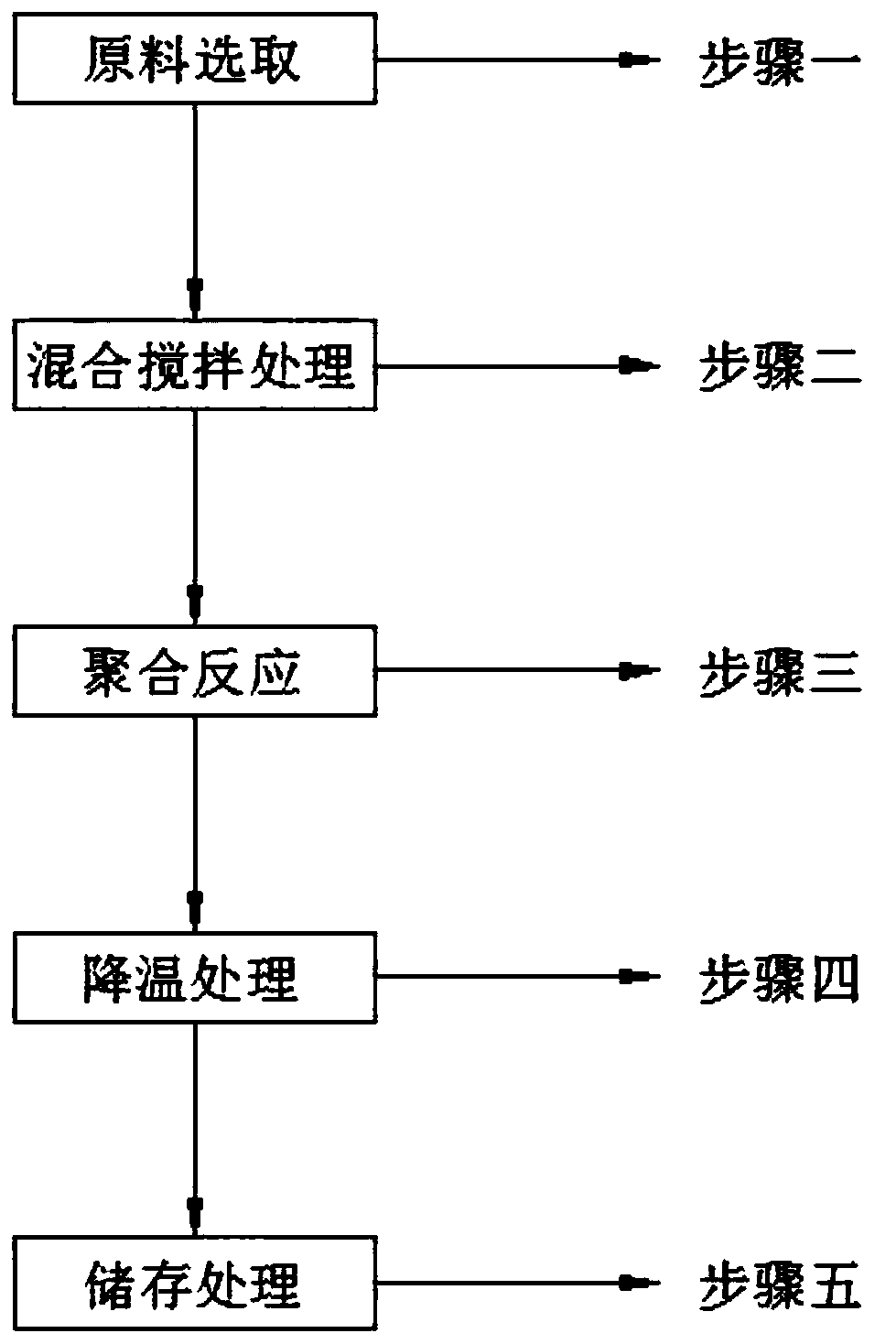

[0027] 1) Each raw material is mixed with 1.5% acrylic acid, 1% hydroxyethyl acrylate, 1% hydroxypropyl acrylate, 1% hydroxybutyl acrylate, 20% isooctyl acrylate, 1.5% dimethacrylic acid The weight percent of ethylene glycol ester, 2% allyl methacrylate, 35% butyl acrylate, 35% solvent and 2% initiator is weighed;

[0028] 2) After that, the raw materials except the initiator are mixed and stirred, and continuously mixed and stirred at 20 to 30 degrees for 10 minutes, so that all components are mixed and stirred evenly;

[0029] 3) Divide the obtained mixed and stirred raw materials into two parts, and add an initiator to the first part to cause a polymerization reaction, and the reaction temperature is controlled between 70 and 80 degrees, and after 30 minutes of reaction, add Add another part of mixing and stirring raw materials, and control the reaction temperature at this time between 65 and 75 degrees, and control the reaction time at 3 hours. After the reaction is comple...

Embodiment 2

[0033] 1) Each raw material is mixed with 1.5% acrylic acid, 1% hydroxyethyl acrylate, 1% hydroxypropyl acrylate, 1% hydroxybutyl acrylate, 25% isooctyl acrylate, 1.5% dimethacrylic acid The weight percent of ethylene glycol ester, 2% allyl methacrylate, 30% butyl acrylate, 35% solvent and 2% initiator is weighed;

[0034] 2) After that, the raw materials except the initiator are mixed and stirred, and continuously mixed and stirred at 20 to 30 degrees for 10 minutes, so that all components are mixed and stirred evenly;

[0035] 3) Divide the obtained mixed and stirred raw materials into two parts, and add an initiator to the first part to cause a polymerization reaction, and the reaction temperature is controlled between 70 and 80 degrees, and after 30 minutes of reaction, add Add another part of mixing and stirring raw materials, and control the reaction temperature at this time between 65 and 75 degrees, and control the reaction time at 3 hours. After the reaction is comple...

Embodiment 3

[0039] 1) Each raw material is mixed with 1.5% acrylic acid, 1% hydroxyethyl acrylate, 1% hydroxypropyl acrylate, 1% hydroxybutyl acrylate, 30% isooctyl acrylate, 1.5% dimethacrylic acid The weight percent of ethylene glycol ester, 2% allyl methacrylate, 25% butyl acrylate, 35% solvent and 2% initiator is weighed;

[0040] 2) After that, the raw materials except the initiator are mixed and stirred, and continuously mixed and stirred at 20 to 30 degrees for 10 minutes, so that all components are mixed and stirred evenly;

[0041]3) Divide the obtained mixed and stirred raw materials into two parts, and add an initiator to the first part to cause a polymerization reaction, and the reaction temperature is controlled between 70 and 80 degrees, and after 30 minutes of reaction, add Add another part of mixing and stirring raw materials, and control the reaction temperature at this time between 65 and 75 degrees, and control the reaction time at 3 hours. After the reaction is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com