Nitrogen functionalized cross-linked polymer binder and lithium-sulfur battery positive electrode material

A technology of cross-linked polymer and positive electrode material is applied in the preparation of positive electrode material of lithium-sulfur battery and the field of cross-linked polymer binder, which can solve the problems of complicated preparation process of porous carbon material, high cost, and low energy density of positive electrode, etc. Achieve the effect of improving charge-discharge cycle performance, strong adhesion, limiting diffusion and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

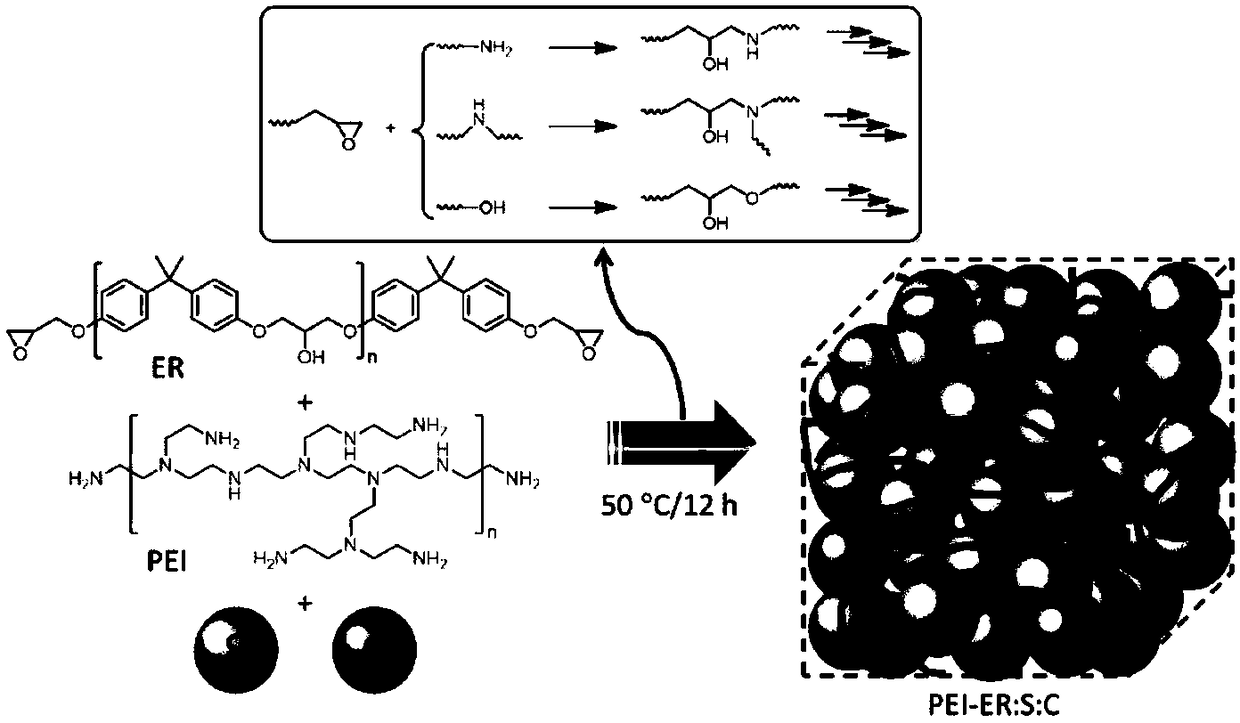

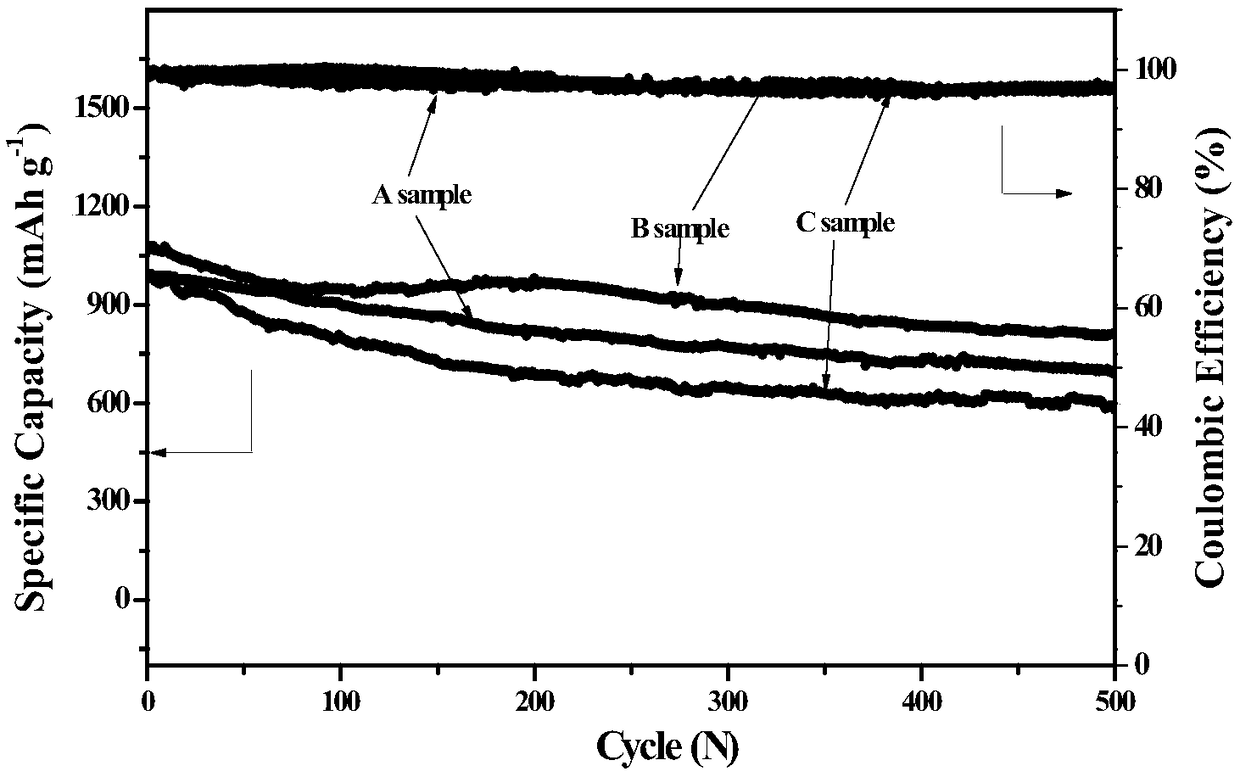

[0025] A nitrogen-functionalized cross-linked polymer binder consisting of bisphenol A-type epoxy resin and polyethyleneimine. The mass ratio of bisphenol A epoxy resin and polyethyleneimine is 1.

[0026] A preparation method for a lithium-sulfur battery cathode material containing a nitrogen-functionalized cross-linked polymer binder, comprising the following steps:

[0027] (1) Dissolve 0.5 parts of polyethyleneimine and 0.5 parts of bisphenol A epoxy resin in N-methylpyrrolidone solvent to form a uniform solution to control the solidification of polyethyleneimine and bisphenol A epoxy resin. The content is 20% by weight.

[0028] (2) Add 7 parts of active sulfur to the above mixture of polyethyleneimine and bisphenol A epoxy resin, then add 2 parts of Super P conductive agent, stir evenly with a glass rod, and ultrasonicate at room temperature for 40 min to prepare the positive electrode mixture.

[0029] (3) After ball milling the above mixed solution at a speed of 400...

Embodiment 2

[0032] A nitrogen functionalized crosslinked polymeric binder consisting of bisphenol A type epoxy resin and polyethyleneimine. Wherein the mass ratio of the bisphenol A epoxy resin to polyethyleneimine is 2:1.

[0033] A preparation method for a lithium-sulfur battery cathode material containing a nitrogen-functionalized cross-linked polymer binder, comprising the following steps:

[0034] (1) Dissolve 0.5 parts of polyethyleneimine and 1 part of bisphenol A epoxy resin in N-methylpyrrolidone solvent to form a uniform solution to control the solidification of polyethyleneimine and bisphenol A epoxy resin. The content is 20% by weight.

[0035] (2) Add 10.5 parts of active sulfur to the above mixture of polyethyleneimine and bisphenol A epoxy resin, then add 3 parts of Super P conductive agent, stir evenly with a glass rod, and ultrasonicate for 40 minutes at room temperature , to prepare the positive electrode mixture.

[0036] (3) After ball milling the above mixed soluti...

Embodiment 3

[0039] A nitrogen functionalized crosslinked polymeric binder consisting of bisphenol A type epoxy resin and polyethyleneimine. Wherein the mass ratio of the bisphenol A epoxy resin to polyethyleneimine is 3:1.

[0040] A preparation method for a lithium-sulfur battery cathode material containing a nitrogen-functionalized cross-linked polymer binder, comprising the following steps:

[0041] (1) Dissolve 0.5 parts of polyethyleneimine and 1.5 parts of bisphenol A epoxy resin in N-methylpyrrolidone solvent to form a uniform solution to control the solidification of polyethyleneimine and bisphenol A epoxy resin. The content is 20% by weight.

[0042] (2) Add 14 parts of active sulfur to the above mixture of polyethyleneimine and bisphenol A epoxy resin, then add 4 parts of Super P conductive agent, stir evenly with a glass rod, and ultrasonicate for 40 minutes at room temperature , to prepare the positive electrode mixture.

[0043] (3) After ball milling the above mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com