Ceramic material with adjustable and controllable negative dielectric performance and preparation method thereof

A ceramic material and negative dielectric technology, applied in the field of metamaterials, can solve the problems of large negative dielectric value and eddy current loss, restricting the development of cermets, etc., and achieve the effects of low preparation cost, considerable performance processing, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

[0027] The invention provides a preparation method of a ceramic material with adjustable negative dielectric properties, which comprises the following steps:

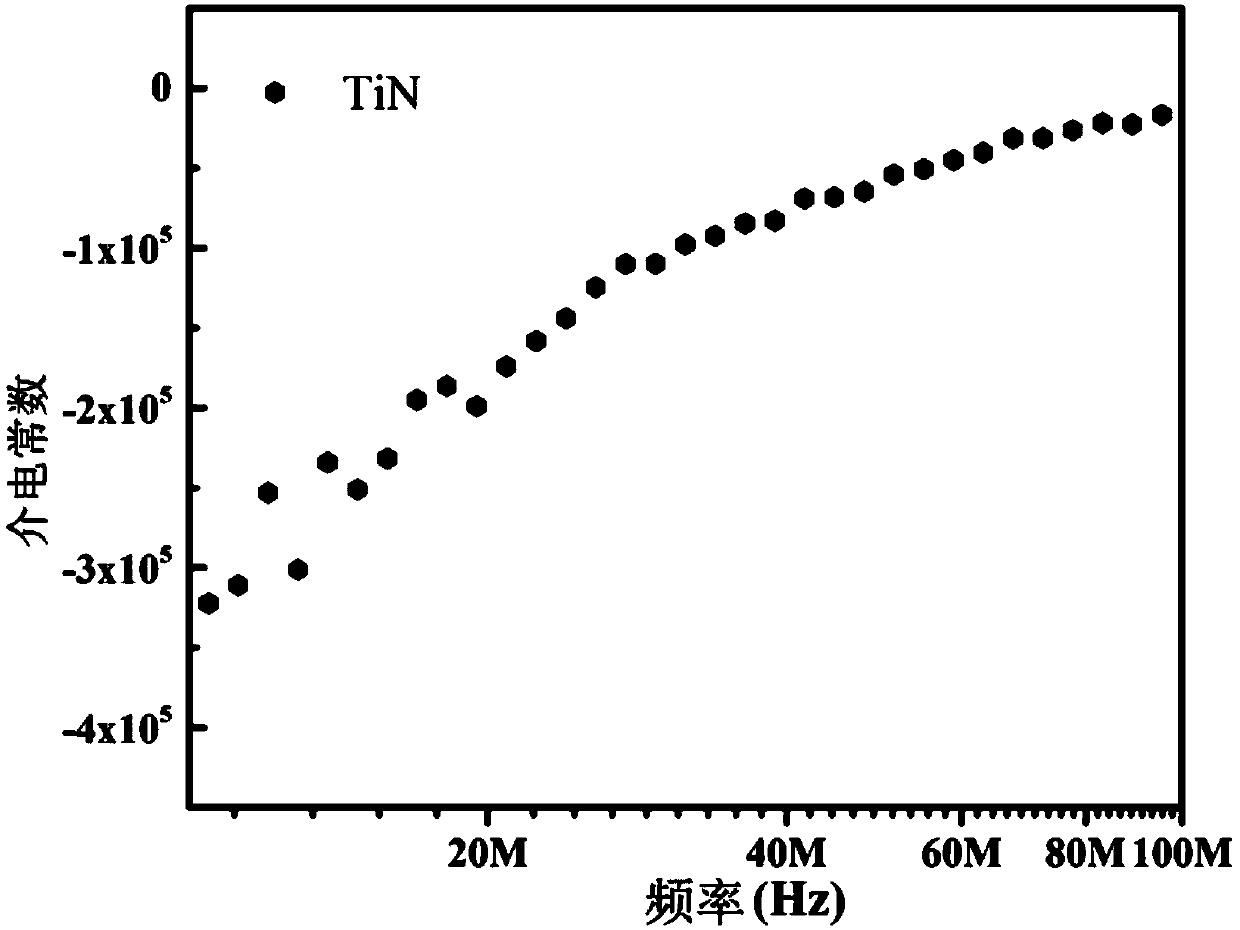

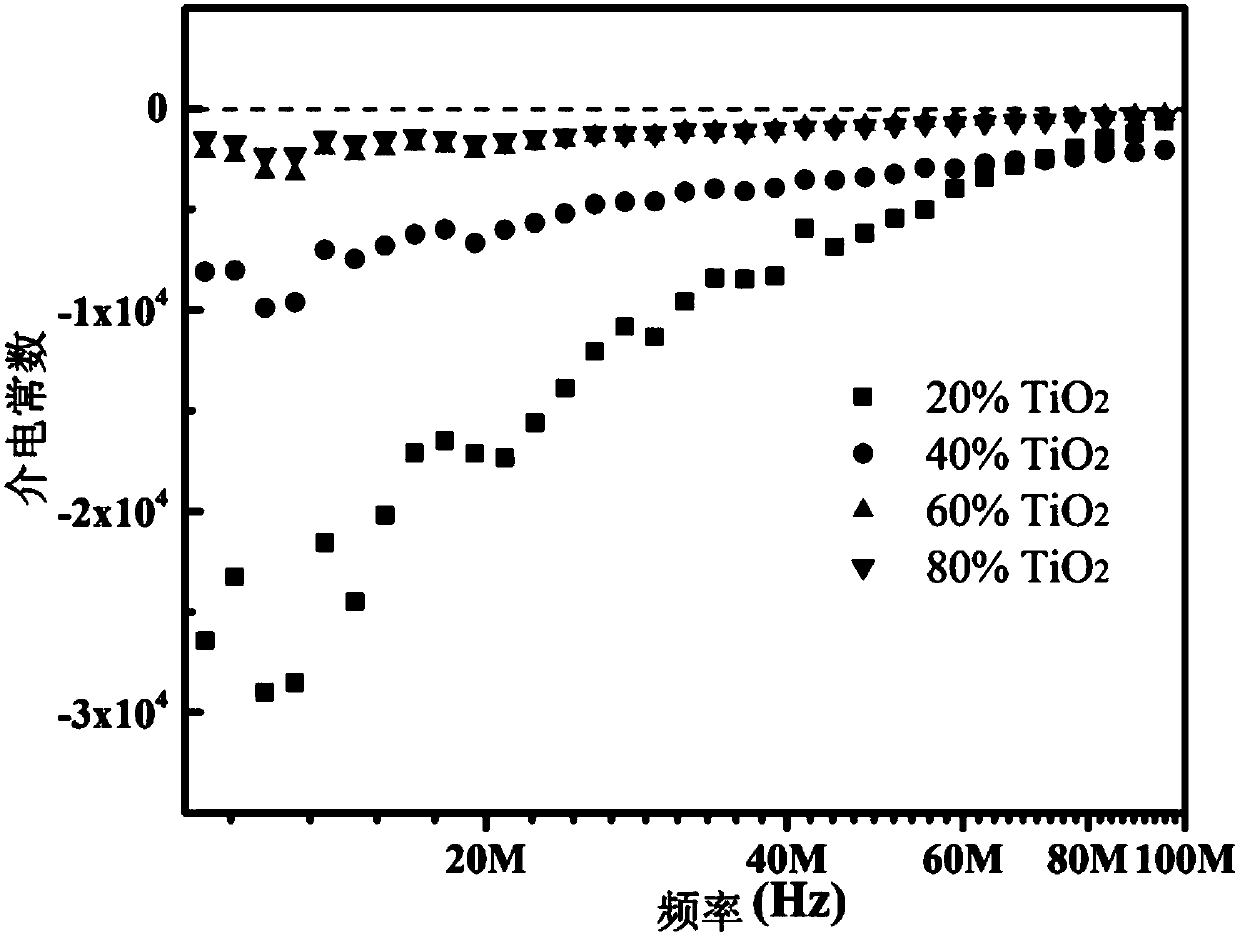

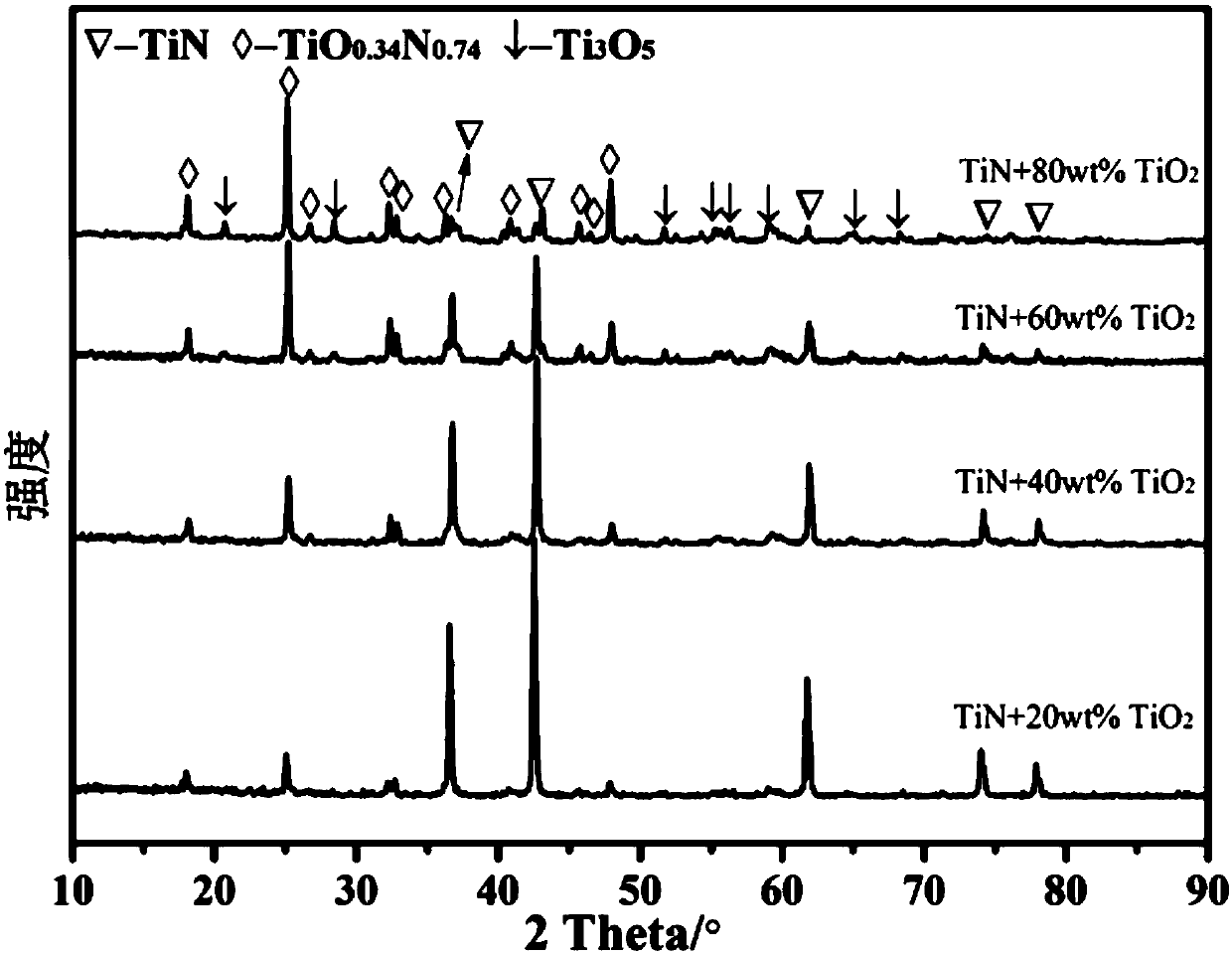

[0028] Step 1: mixing materials: by mass percentage, mixing 80% to 20% of titanium nitride powder and 20% to 80% of titanium oxide powder as raw materials to obtain a mixed powder;

[0029] Step 2: Granulating and compacting: adding binder to the mixed powder, grinding and granulating, and then pressing to obtain a green body;

[0030] Step 3: Sintering: the green body is placed in a protective atmosphere for sintering to obtain a ceramic material with adjustable negative dielectric properties.

[0031] In one embodiment, the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com