A kind of friction stir welding stirring head material and preparation method of stirring head

A friction stir welding and stirring head technology, which is applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of low mechanical properties, short service life and high production cost of the stirring head, so as to shorten the sintering time and improve the service life , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

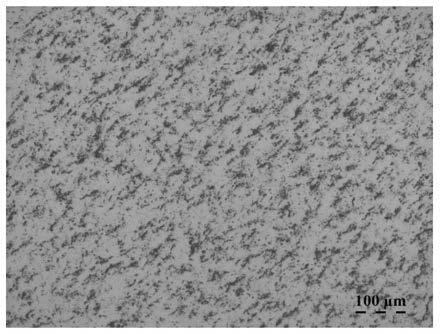

Embodiment 1

[0028] According to the method of the present invention, raw material adopts 80% tungsten powder and 20% titanium carbide powder (80%W+20%TiC), wherein, the purity of two kinds of powders is 99.99%, the particle size of tungsten powder is 8 μm, titanium carbide The particle size of the powder is 8 μm; mix the above alloy powder evenly and put it into the stirring head mold prepared in advance, and put it into the sintering furnace after compaction for hot pressing sintering. The process steps and parameters are as follows: 1) Raise the temperature of the furnace To 2000°C, apply a pressure of 20MPa, and keep warm for 1h; 2) After the sintering furnace is naturally cooled to room temperature, take out the stirring head for fine polishing.

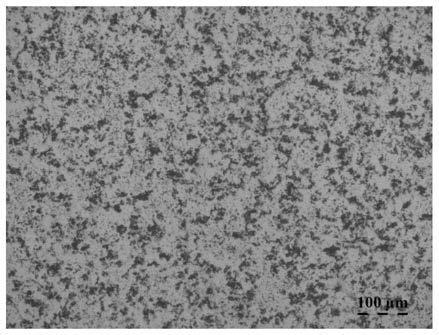

Embodiment 2

[0030] According to the method of the present invention, raw material adopts 80% tungsten powder and 20% zirconium carbide powder (80%W+20%ZrC), wherein, the purity of two kinds of powders is 99.99%, the particle size of tungsten powder is 8 μm, zirconium carbide The particle size of the powder is 8 μm; mix the above alloy powder evenly and put it into the stirring head mold prepared in advance, and put it into the sintering furnace after compaction for hot pressing sintering. The process steps and parameters are as follows: 1) Raise the temperature of the furnace To 2000°C, apply a pressure of 20MPa, and keep warm for 1h; 2) After the sintering furnace is naturally cooled to room temperature, take out the stirring head for fine polishing.

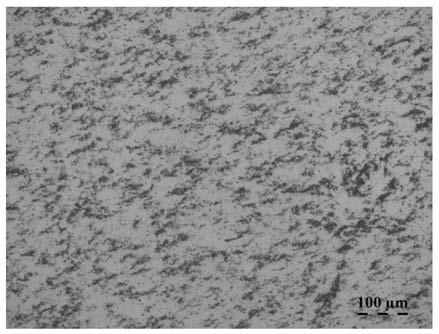

Embodiment 3

[0032] According to the method of the present invention, the raw material is 80% tungsten powder plus 10% titanium carbide powder and 10% zirconium carbide powder (80%W+10%TiC+10%ZrC), wherein the purity of the two powders is 99.99%. The particle size of the tungsten powder is 8 μm, the particle size of the titanium carbide powder and zirconium carbide powder is 8 μm; mix the above alloy powder evenly and put it into the mixing head mold made in advance, press it and put it into the sintering furnace for sintering. The process steps and parameters are as follows: 1) Gradually raise the furnace temperature to 2000°C, apply a pressure of 20 MPa, and keep it for 1 hour; 2) After the sintering furnace is naturally cooled to room temperature, take out the stirring head for fine polishing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com