Alloy roll ring for hot rollinig seamless steel tube production and production method thereof

A technology of alloy roll ring and seamless steel pipe, which is applied in the field of metallurgy, can solve the problems of large radial force, difficulty in bonding, uneven stress of different material layers, etc., and achieve the effect of increasing service life and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

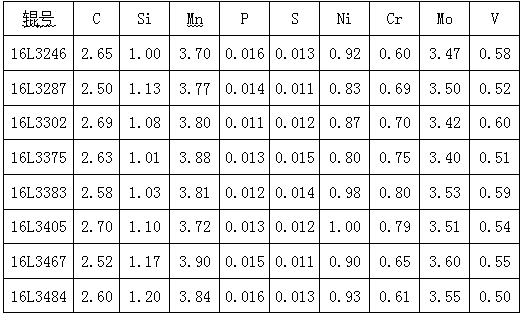

[0037] In this embodiment, the specification of the centrifugal composite roller ring is Φ280*157, and the roller number is 16L3246. The percentage content is shown in Table 1 and Table 2.

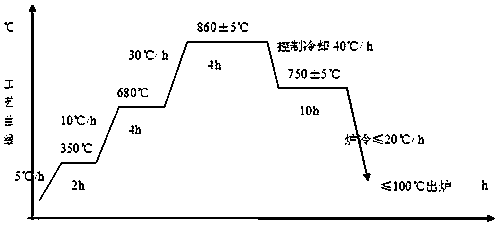

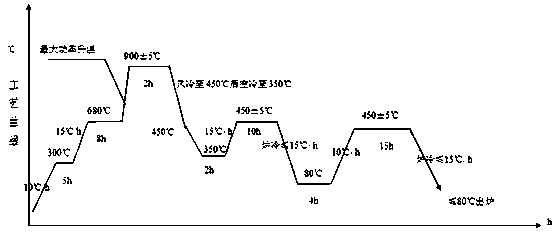

[0038] The production process of the centrifugal composite roller ring in this embodiment also includes the following process steps:

[0039] (1) Iron and molten steel modification process: 1.5t and 1t intermediate frequency induction furnaces are used to smelt the outer layer of molten iron and inner layer of molten steel.

[0040] After the outer metal material is completely melted, add broken glass on the molten iron surface to prevent oxidation. The amount added is 5.3kg per ton of molten metal. 10 minutes before tapping, add ferrovanadium with a molten iron content of 0.4% in the furnace, with a particle size of 10mm. Add 1.0% ferrochromium nitride in 7 minutes, particle size 24mm;

[0041] Add 0.28% of silicon-zirconium alloy and 0.4% of modification treatment agent into the pouring ...

Embodiment 2

[0048] The specification of the alloy roll ring in this embodiment is Φ280*157, the roll number is 16L3287, and the structure is a two-layer centrifugal composite structure. The outer layer is made of high manganese molybdenum cast iron, and the inner layer is made of graphite steel. See Table 1 and Table 2 for their content.

[0049] The production process of the alloy roller ring in this embodiment includes iron and molten steel metamorphism treatment, centrifugal casting, and heat treatment processes. The specific process steps are as follows:

[0050] (1) Iron and molten steel modification process: 1.5t and 1t intermediate frequency induction furnaces are used to smelt the outer layer of molten iron and inner layer of molten steel.

[0051] After the outer metal material is completely melted, add broken glass on the molten iron surface to prevent oxidation. The amount added is 5kg per ton of molten metal. 8 minutes before tapping, add ferrovanadium with a molten iron conte...

Embodiment 3

[0059] The specification of the alloy roll ring in this embodiment is Φ280*157, the roll number is 16L3302, and the structure is a two-layer centrifugal composite structure. See Table 1 and Table 2 for their content.

[0060] The production process of the alloy roller ring in this embodiment includes iron and molten steel metamorphism treatment, centrifugal casting, and heat treatment processes. The specific process steps are as follows:

[0061] (1) Iron and molten steel modification process: 1.5t and 1t intermediate frequency induction furnaces are used to smelt the outer layer of molten iron and inner layer of molten steel.

[0062] After the outer metal material is completely melted, add broken glass on the molten iron surface to prevent oxidation. The amount added is 5.7kg per ton of molten metal. 9 minutes before tapping, add ferrovanadium with 0.5% molten iron in the furnace, with a particle size of 18mm. Add 1.0% ferrochrome nitride in 6 minutes, particle size 27mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com