Antibacterial finishing agent and preparation method and application thereof

An antibacterial finishing agent and post-finishing technology, which is applied in fiber treatment, textiles and papermaking, biochemical fiber treatment, etc., can solve the problems of no health care effect, toxic and side effects, and unreliable safety, so as to facilitate industrial production and maintain antibacterial Ability to enhance the effect of antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

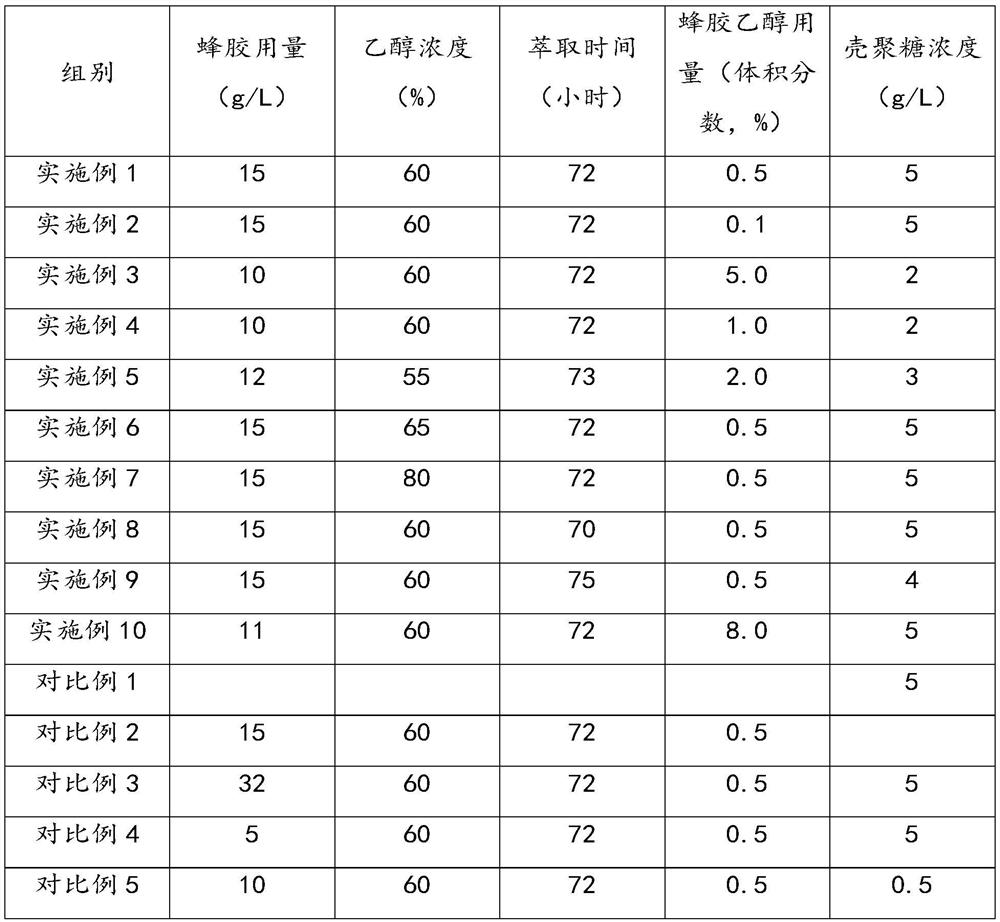

[0076] The preparation method of the antibacterial finishing agent is generally to prepare respectively a certain concentration of propolis ethanol solution and a certain concentration of chitosan solution, and then measure a certain volume of propolis ethanol solution, which is added to the prepared chitosan solution, Mix and stir until smooth.

[0077] Because propolis is insoluble in water and can be dissolved in organic solvents such as ethanol, ethanol is preferred as the solvent for dissolving propolis, and ethanol is non-toxic and volatile, and will not cause residues on fabrics. In a sense, ethanol is also green and environmentally friendly product.

[0078]The above-mentioned preparation operation is simple, practical, easy to implement, high in efficiency, low in cost, does not require complicated operating equipment, and is industrialized and mass-produced.

[0079] In a preferred embodiment, the preparation method of propolis ethanol solution comprises:

[0080] ...

Embodiment 1

[0098] An antibacterial finishing agent, comprising the following components:

[0099] 15g / L propolis ethanol solution and 5g / L chitosan solution.

[0100] Wherein, the preparation method of propolis ethanol solution comprises:

[0101] 15 g of propolis was weighed, chopped, added to 1000 mL of ethanol solution with a volume concentration of 60%, extracted at room temperature for 72 hours, and impurities were removed to obtain propolis ethanol solution.

[0102] The application method of this antibacterial finishing agent comprises:

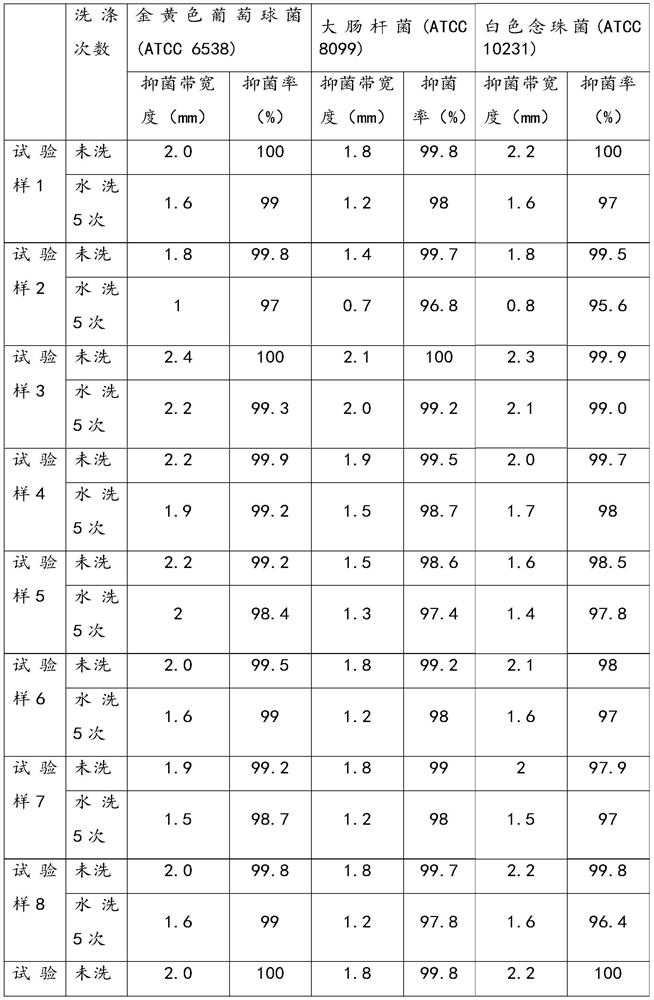

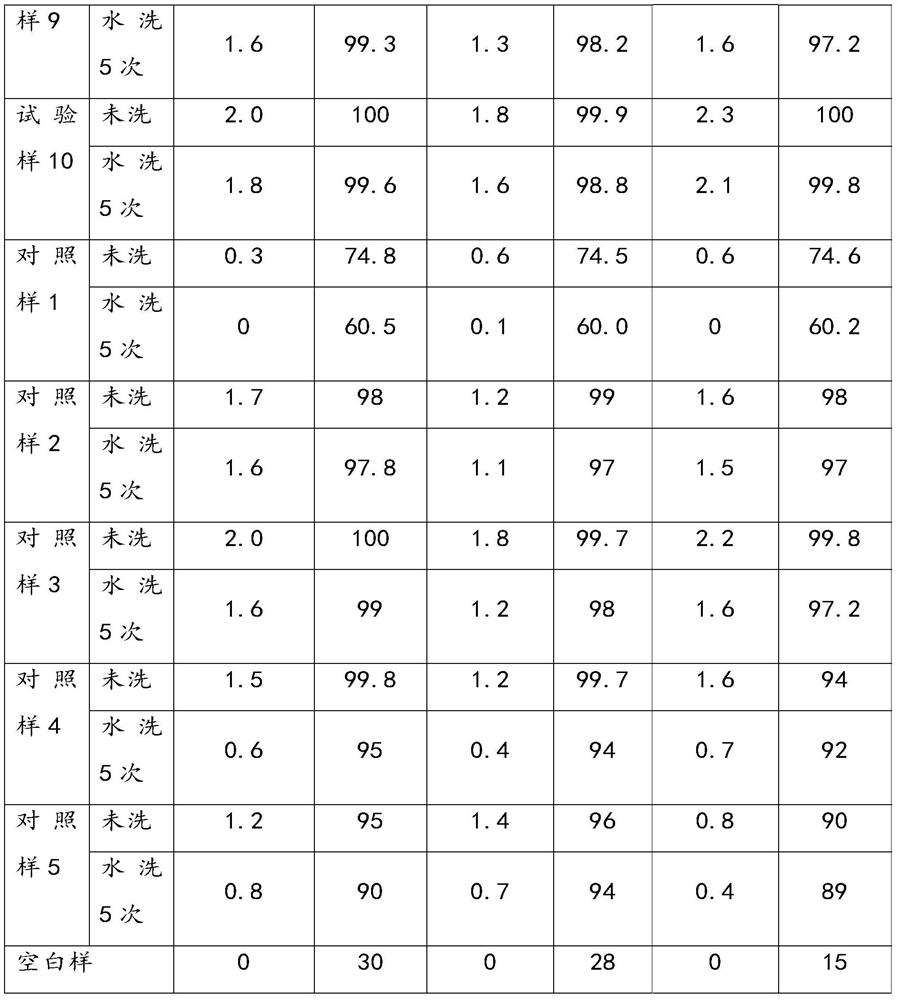

[0103] Measure the propolis ethanol solution 5mL of prepared 15g / L, join in the chitosan solution of 995mL 5g / L, fully stir, obtain antibacterial finishing dispersion liquid, this antibacterial finishing dispersion liquid is equivalent to 0.5% (volume fraction ) of propolis 60% ethanol solution. Padding pure cotton 40s / 144×96 satin fabric, adopting the method of one dipping and one padding, the padding ratio is 80%, and drying at 120°C. After...

Embodiment 2

[0105] The difference with Embodiment 1 is that in this embodiment:

[0106] Methods of application of antimicrobial finishes include:

[0107] Measure the prepared 15g / L propolis ethanol solution 1mL, join in the chitosan solution of 999mL 5g / L, fully stir, obtain antibacterial finishing dispersion liquid, this antibacterial finishing dispersion liquid is equivalent to 0.1% (volume fraction ) of propolis 60% ethanol solution. Padding pure cotton 40s / 144×96 satin fabric, adopting the method of one dipping and one padding, the padding ratio is 80%, and drying at 120°C. After padding, the remaining working solution is kept and placed to observe the stability of the working solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com