Claw pole disc asynchronous electric motor

An asynchronous motor and electric motor technology, which is applied to asynchronous induction motors, electric components, electromechanical devices, etc., can solve the problems of inability to start directly, no fixed rotation direction, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further described below in conjunction with accompanying drawing.

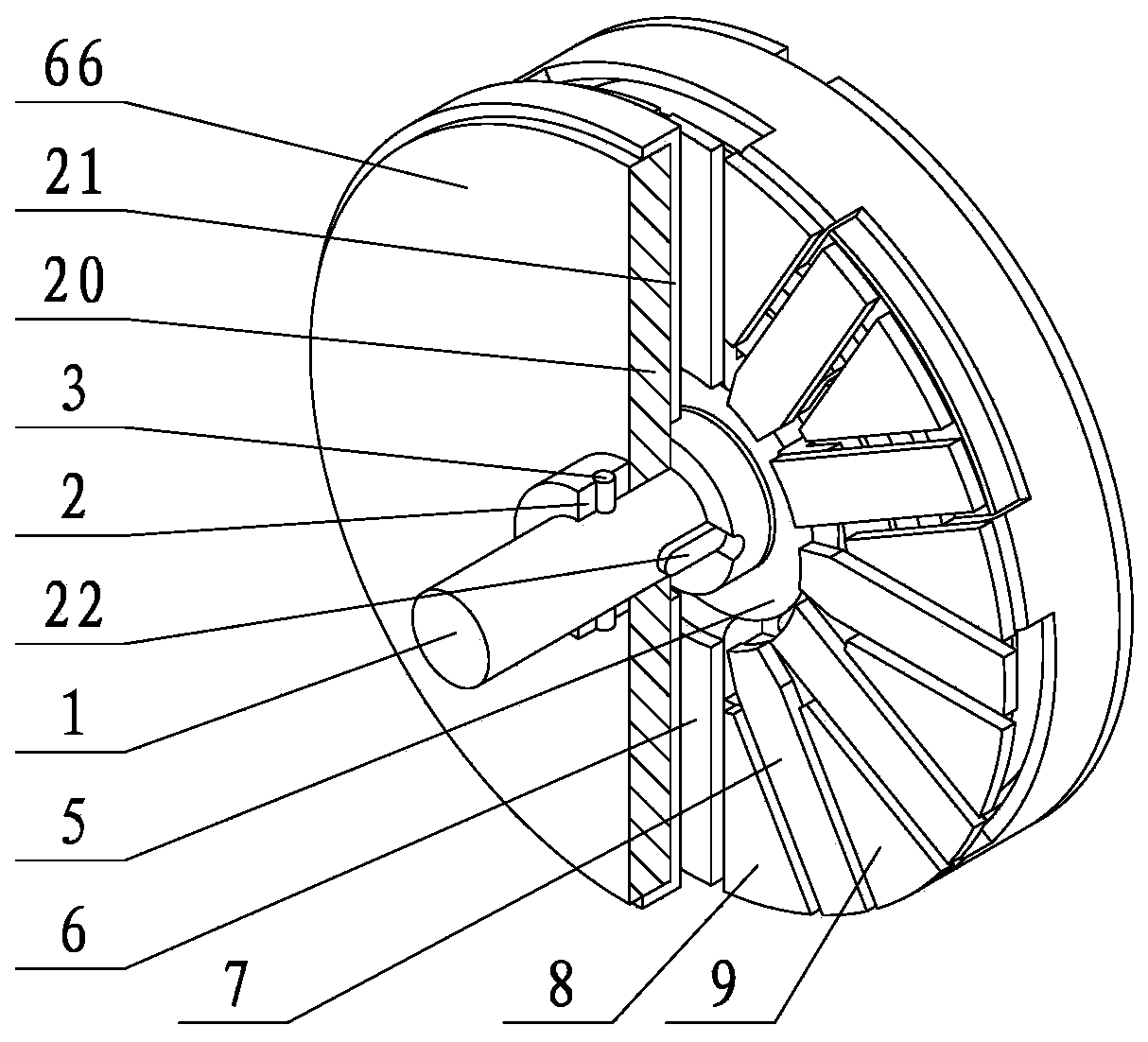

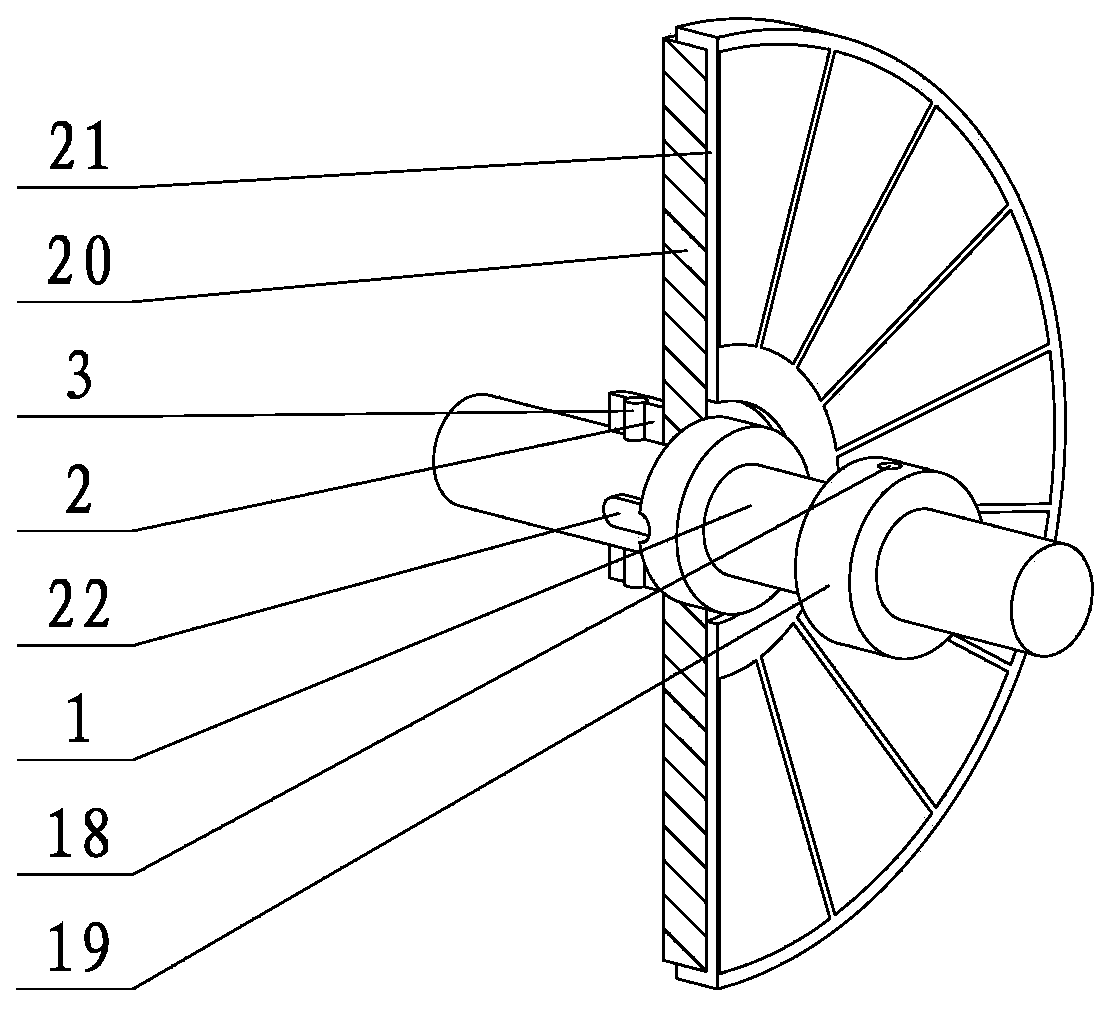

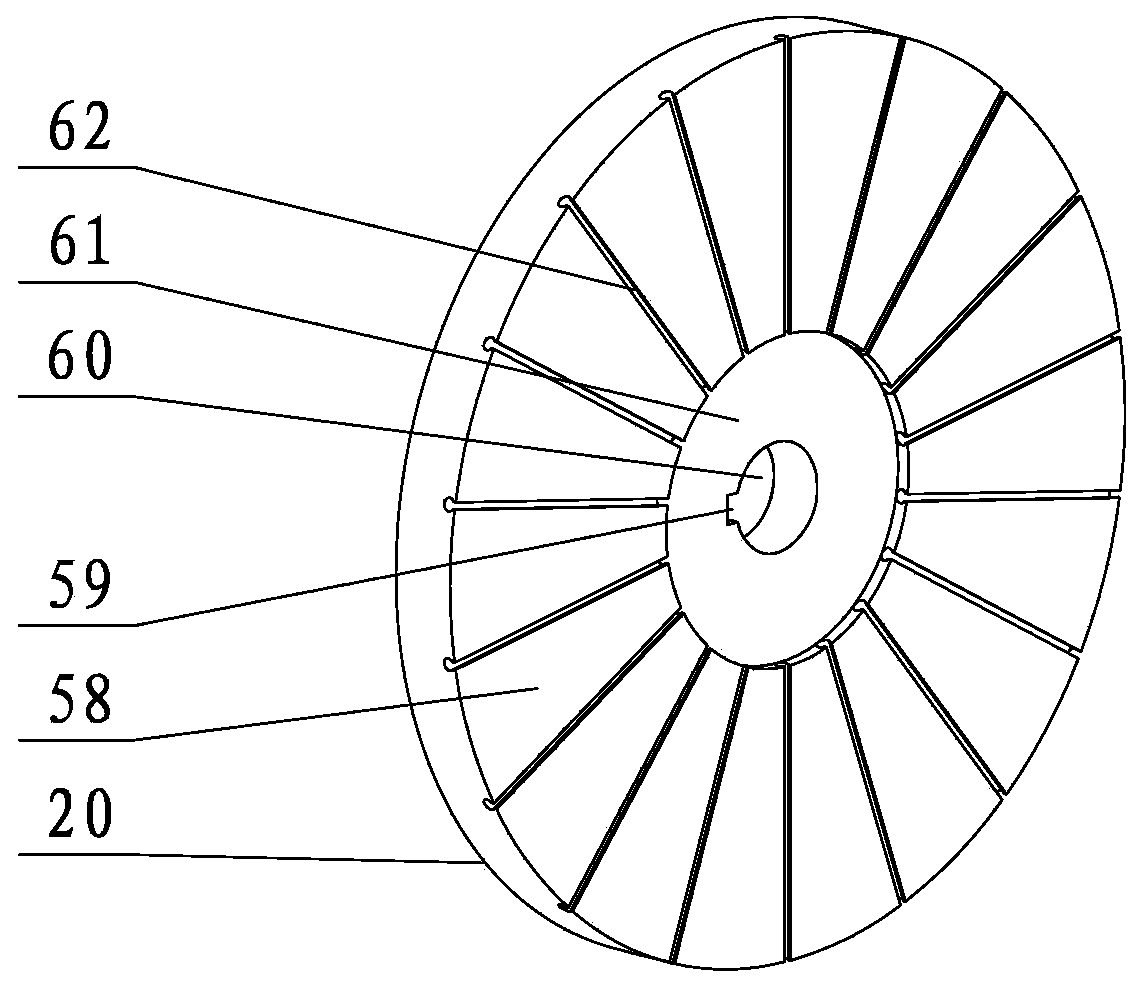

[0050] refer to figure 1 , figure 2 , Figure 8 , Figure 20 , The motor includes a rotor part and a stator part. The rotor parts include rotating shaft 1, retaining ring two 2, positioning pin two 3, positioning pin one 18, retaining ring one 19, rotor iron core 20, disc type squirrel cage 21, key bar 22. Stator parts include bushing two 4, fixed bracket 5, bushing one 17, stator core part one 6, stator core part two 7, stator core part three 8, stator core part four 9, inner yoke ring 16 , Outer yoke ring 12, magnetic isolation sleeve 13, working winding coil 14, bobbin one 15, starting winding coil 10, bobbin two 11. The rotor part is mounted on one axial side of the stator part.

[0051] The claw pole 1 38 of the stator core part 1 6 of the stator part and the claw pole 2 43 of the stator core part 2 7 are arranged at intervals along the circumferential direction on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com