A kind of baby toddler insole

A technology for infants and insoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

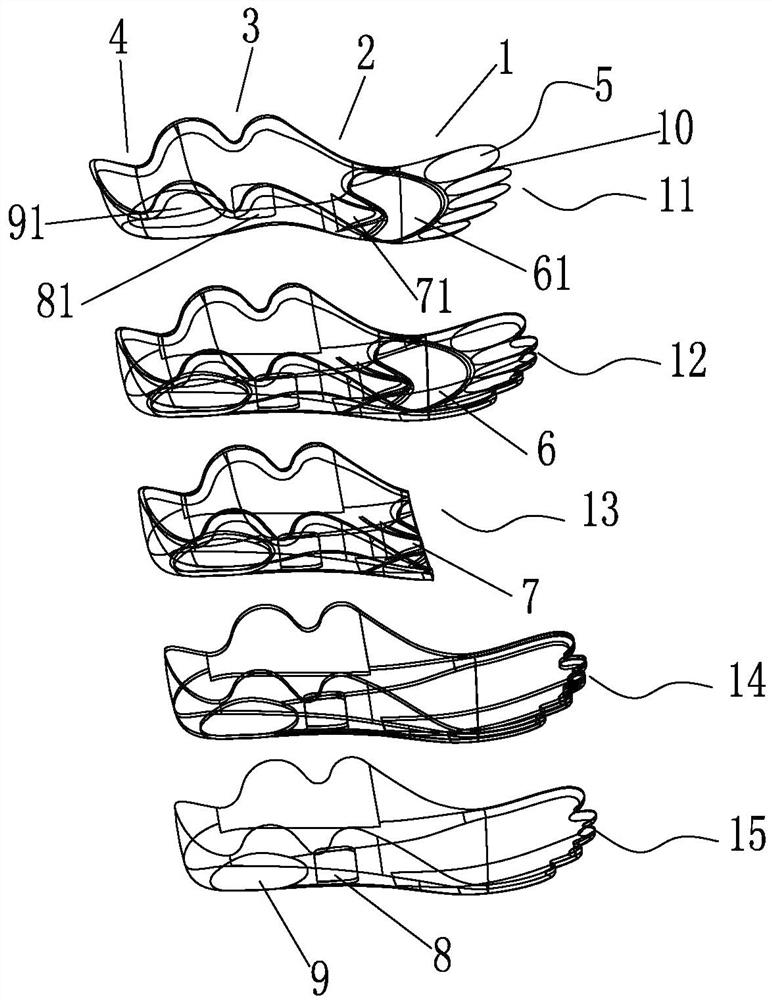

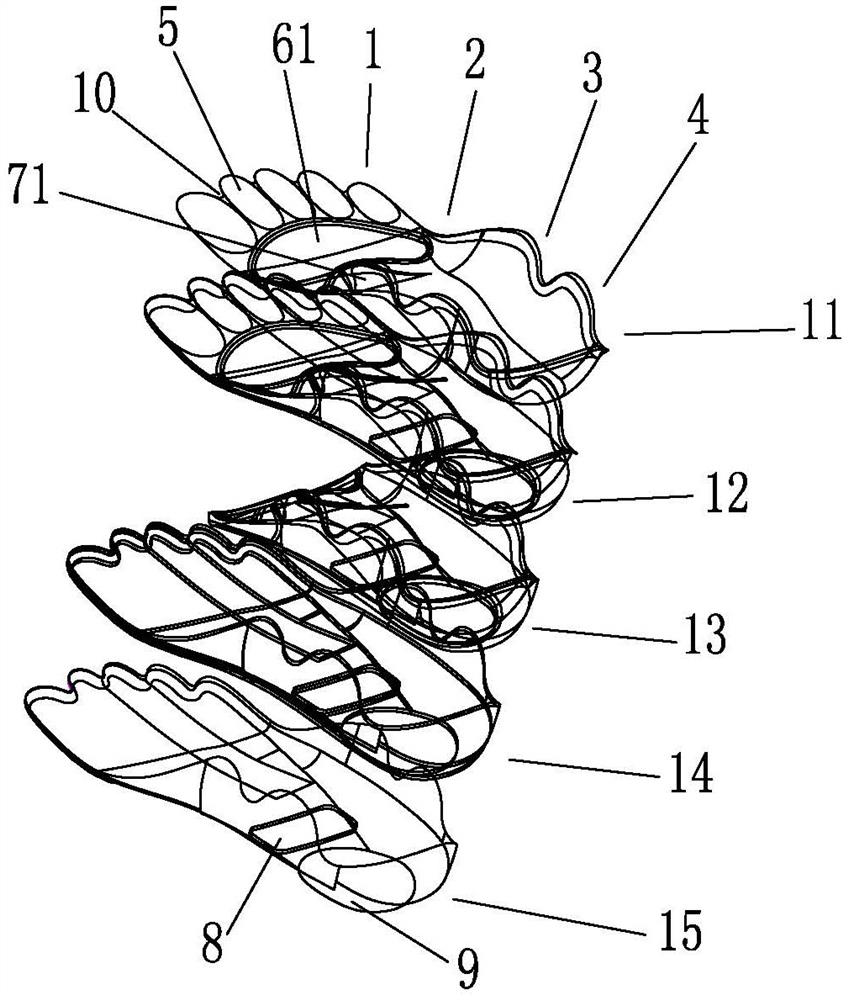

Image

Examples

Embodiment 1

[0044] The first nano-bamboo charcoal fiber layer and the second nano-bamboo charcoal fiber layer of embodiment 1 are all made up of bamboo charcoal particles, nano-silver particles, viscose fibers and additives,

[0045] The bamboo charcoal particle is 8.0% of the weight percentage of the nano-bamboo charcoal fiber layer, and the particle diameter of the bamboo charcoal particle is 1.45 μm;

[0046] The nano-silver particle is 0.04‰ of the weight percentage of the nano-bamboo charcoal fiber layer, and the particle size of the nano-silver particle is 44nm;

[0047] The viscose fiber contains 0.8% ceramic powder, iron powder and coupling agent, the coupling agent is 0.1% of the weight of the viscose fiber, and the ceramic powder is made of the following components by weight percentage: 50% zirconium dioxide, silicon dioxide 35%, titanium dioxide 5%, and described coupling agent is glyceryl stearate;

[0048] The additive is honeysuckle extract, and the honeysuckle extract is 0...

Embodiment 2

[0063] The first nano-bamboo charcoal fiber layer and the second nano-bamboo charcoal fiber layer of embodiment 2 are all made up of bamboo charcoal particles, nano-silver particles, viscose fibers and additives,

[0064] Described bamboo charcoal particle is 11% of nano bamboo charcoal fiber layer weight percent, and the particle diameter of described bamboo charcoal particle is 1.0 μ m;

[0065] Described nano-silver particle is 0.03% of the weight percent of nano-bamboo charcoal fiber layer, and described nano-silver particle diameter is 35nm;

[0066] The viscose fiber contains 1% ceramic powder, iron powder and coupling agent, the coupling agent is 0.3% of the weight of the viscose fiber, and the ceramic powder is made of the following components by weight percentage: 60% zirconium dioxide, silicon dioxide 40%, titanium dioxide 15%, and described coupling agent is glyceryl stearate;

[0067] The additive is two kinds of honeysuckle and isatis root extract, the honeysuckl...

Embodiment 3

[0082] Embodiment 3 The first nano-bamboo charcoal fiber layer and the second nano-bamboo charcoal fiber layer are all made up of bamboo charcoal particles, nano-silver particles, viscose fibers and additives,

[0083] Described bamboo charcoal particle is 9.5% of nano bamboo charcoal fiber layer weight percent, and the particle diameter of described bamboo charcoal particle is 1.1 μ m;

[0084] The nano-silver particle is 0.01% of the weight percentage of the nano-bamboo charcoal fiber layer, and the particle diameter of the nano-silver particle is 45nm;

[0085] Contain 0.9% ceramic powder, iron powder and coupling agent in the described viscose fiber, and coupling agent is 0.2% of viscose fiber weight, and ceramic powder is made of following composition by weight percentage: zirconium dioxide 55%, silicon dioxide 39%, titanium dioxide 12%, and described coupling agent is glyceryl stearate;

[0086] The additive is Radix isatidis extract, and the Radix Radix isatidis extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com