Fast cooling type Na<131>I destructive distillation production device

A production device, cold technology, applied in the field of fast-cooling Na131I dry distillation production device, can solve the problems of unfavorable safety production, shorten the service life of production device, increase maintenance and repair personnel, etc., achieve efficient capture, shorten cooling time, production The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

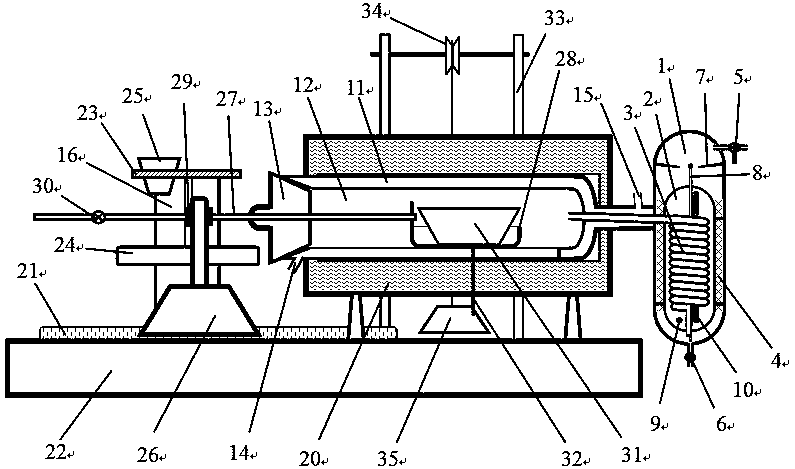

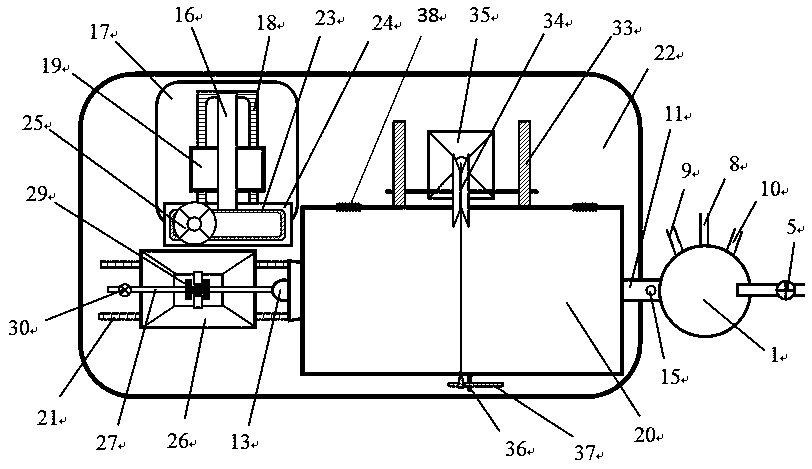

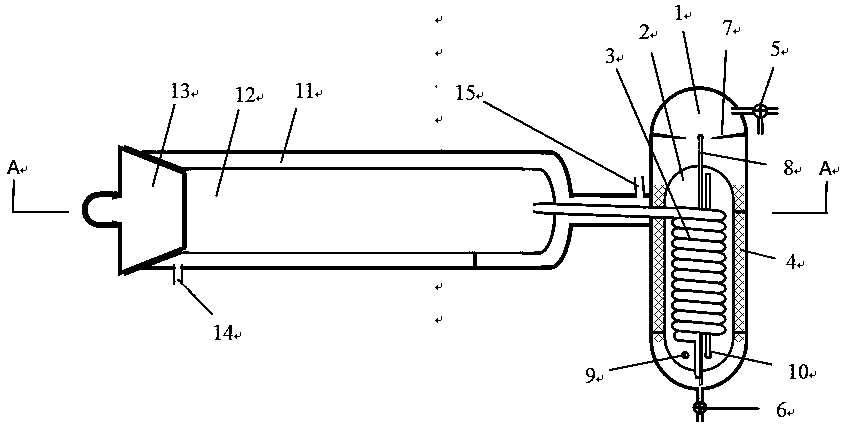

[0028] figure 1 Is a kind of rapid cooling Na of the present invention 131 The overall structure schematic diagram of 1 retort production unit, figure 2 Is a kind of rapid cooling Na of the present invention 131 The top view structure schematic diagram of I retort production device, image 3 It is a structural representation of the distillation absorber in the present invention, Figure 4 yes image 3 A-A sectional view of, Figure 5 It is a structural schematic diagram of the feeding platform in the present invention. exist Figure 1~Figure 5 Among them, a kind of rapid cooling Na of the present invention 131 1 dry distillation production device, including distillation absorber, feeding table, loading table, counterweight, heating furnace 20, slide rail 21, workbench 22. The connection relationship of the above dry distillation production device is that the distillation absorber part is placed in the cavity of the heating furnace 20, the feeding table, the counterwei...

Embodiment 2

[0039] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the angle between the upper end pipe of the coil pipe 3 and the horizontal line is 10°, and the opening angle of the upper half of the heating furnace with the hinge as the axis is 105°. The gap between the tube 11 and the side wall of the distillation tube 12 was 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com