Method for spraying nanometer paint on display board

A display board and nano technology, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, can solve the problems of deformation of painting materials and failure of painting, and achieve the effect of reducing waste of heat and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

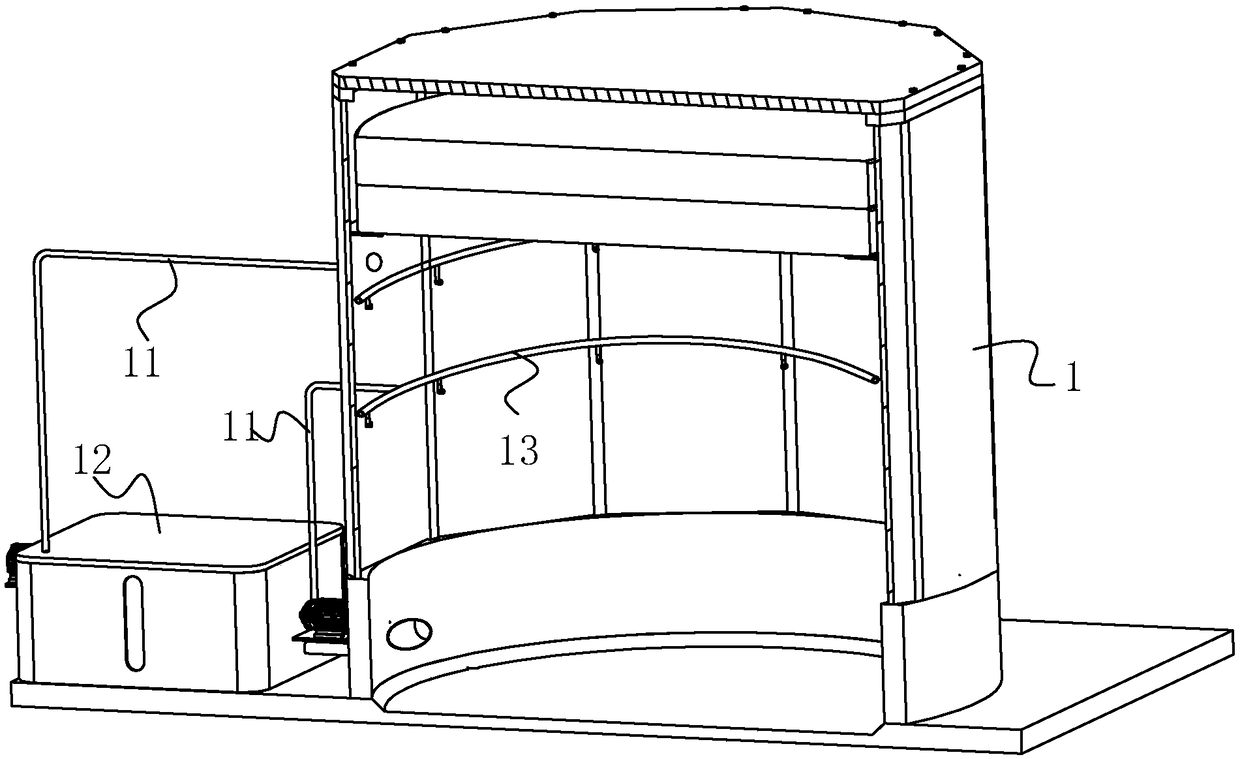

[0036] In an embodiment, a method for spraying nano paint on a display board includes the following steps:

[0037] Step 1: Take out the MDF soaked in maple oil, and dry the MDF with maple oil naturally at a temperature of 25 degrees. After the MDF is air-dried, it is polished with a grinding wheel to remove the raised foreign matter on the surface of the MDF;

[0038] Spray the polished MDF once with PE primer, and the PE primer is white; white is used as the base color to facilitate the coloring of other colors in the later stage;

[0039] After the PE primer is air-dried, it is fixed, and then the PE primer is artificially polished twice with 800-mesh sandpaper to make the surface of the PE primer smoother.

[0040] Step 2: Spray the conductive primer on the surface of the PE primer. The conductive primer has color, so the MDF can get the desired color through the conductive primer. The conductive base coat is mixed with conductive powder and colored powder.

[0041] It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com