Solid-liquid separation method and device for viscous material

A technology of solid-liquid separation and materials, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve the problems of high moisture content of sludge, resource waste environment, and no industrialized production, etc. problems, to achieve the effect of high processing efficiency, environmental protection and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further explained below in conjunction with the drawings.

[0056] A solid-liquid separation method for viscous materials includes the following steps:

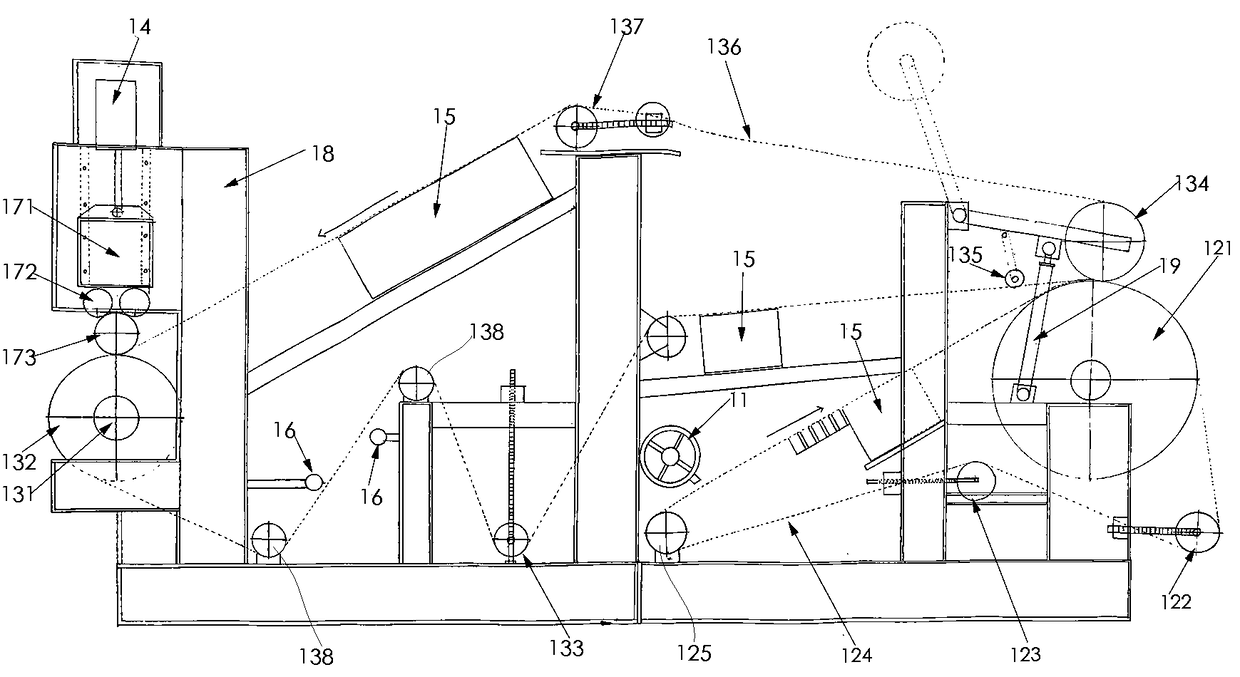

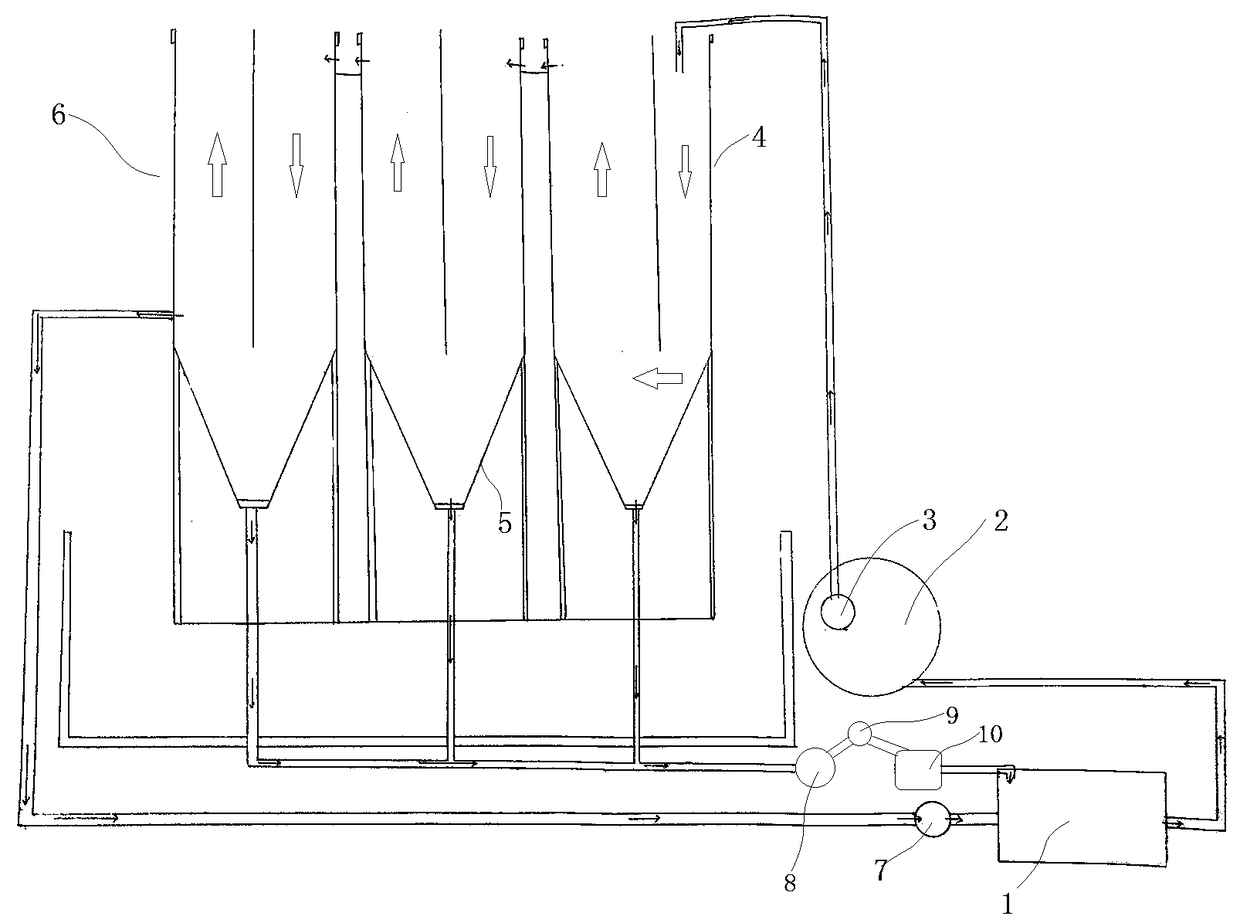

[0057] 1) The motor 131 drives the breast roller 132 to rotate to drive the felt 136 to move. The material is physically stirred in the mixing tank 8 and then sent to the feeding tank 10 by the feeding pump 9; then the material is continuously input into the host 1 and discharged through the nozzle 11 On the conveying mechanism 12;

[0058] 2) After the material is conveyed by the filter belt 124 of the conveying mechanism 12 and is initially vacuum drained by the vacuum box 15 at its input section, the material runs to the mesh cage 121 and the auxiliary roller 134 to complete the first extrusion and drainage, and then the material adheres Continue to move after passing the secondary roller 134 on the felt 136;

[0059] 3) The material follows the felt 136 to the output section, and the second v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com