Heat-insulating fire-proof cable material and preparation method thereof

A technology of fireproof cables and raw materials, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as life safety and property damage, failure to achieve heat insulation and fire prevention, and personnel health hazards, achieving high safety , excellent performance, uniform properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of flame retardant polyether:

[0031] Add inorganic fluoride, polyether, catalyst, and polytetrafluoroethylene with a mass ratio of 1-2:0.5-0.8:1.4-2.3:1.5-3 in a closed reactor. In non-oxygen conditions, the temperature is 500-700 Under the reaction conditions of ℃, pressure 70-90Mpa, and voltage 1.5-23,000 volts, mixing and stirring for 1-3 hours, the flame-retardant polyether is obtained.

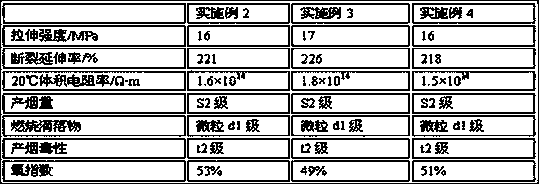

Embodiment 2

[0033] Heat insulation and fireproof cable material preparation:

[0034] Specifically include the following steps:

[0035] (1) Weigh 60Kg polyvinyl chloride, 10Kg hydroxide, 15Kg expandable graphite, 10Kg flame-retardant polyether, 2Kg plasticizer, 5Kg toughening agent, 3Kg antioxidant, and set aside;

[0036] (2) Weigh the hydroxide, expandable graphite, and flame-retardant polyether in step (1) and add them to a high-speed mixer in order to stir. The temperature is controlled at 60°C and the time is 5 minutes to obtain a uniform mixture;

[0037] (3) Add the polyvinyl chloride, plasticizer, toughening agent, and antioxidant weighed in step (1) to the homogeneous mixture prepared in step (2) and continue stirring at a high speed. The temperature is controlled at 100°C. Time 15min;

[0038] (4) Add the product in step (3) to a twin-screw extruder to plasticize, extrude and granulate, pass through a vibrating screen, and then cool and pack.

Embodiment 3

[0040] Heat insulation and fireproof cable material preparation:

[0041] Specifically include the following steps:

[0042] (1) Weigh 70Kg polyvinyl chloride, 15Kg hydroxide, 17Kg expandable graphite, 15Kg flame-retardant polyether, 3Kg plasticizer, 6Kg toughening agent, 5Kg antioxidant, and set aside;

[0043] (2) Weigh the hydroxide, expandable graphite, and flame-retardant polyether in step (1) and add them to a high-speed mixer in order to stir. The temperature is controlled at 70°C and the time is 4 minutes to obtain a uniform mixture;

[0044] (3) Add the polyvinyl chloride, plasticizer, toughening agent, and antioxidant weighed in step (1) to the homogeneous mixture prepared in step (2) in sequence and continue stirring at a high speed. The temperature is controlled at 120°C. Time 12min;

[0045] (4) Add the product in step (3) to a twin-screw extruder to plasticize, extrude and granulate, pass through a vibrating screen, and then cool and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com