Real-time data transmission system for mine automation system

A real-time data transmission and automation system technology, applied in the transmission system, electrical components, etc., can solve the problems of less monitoring information, slow page response, crash, etc., and achieve the effect of reducing burden, improving reliability, and simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

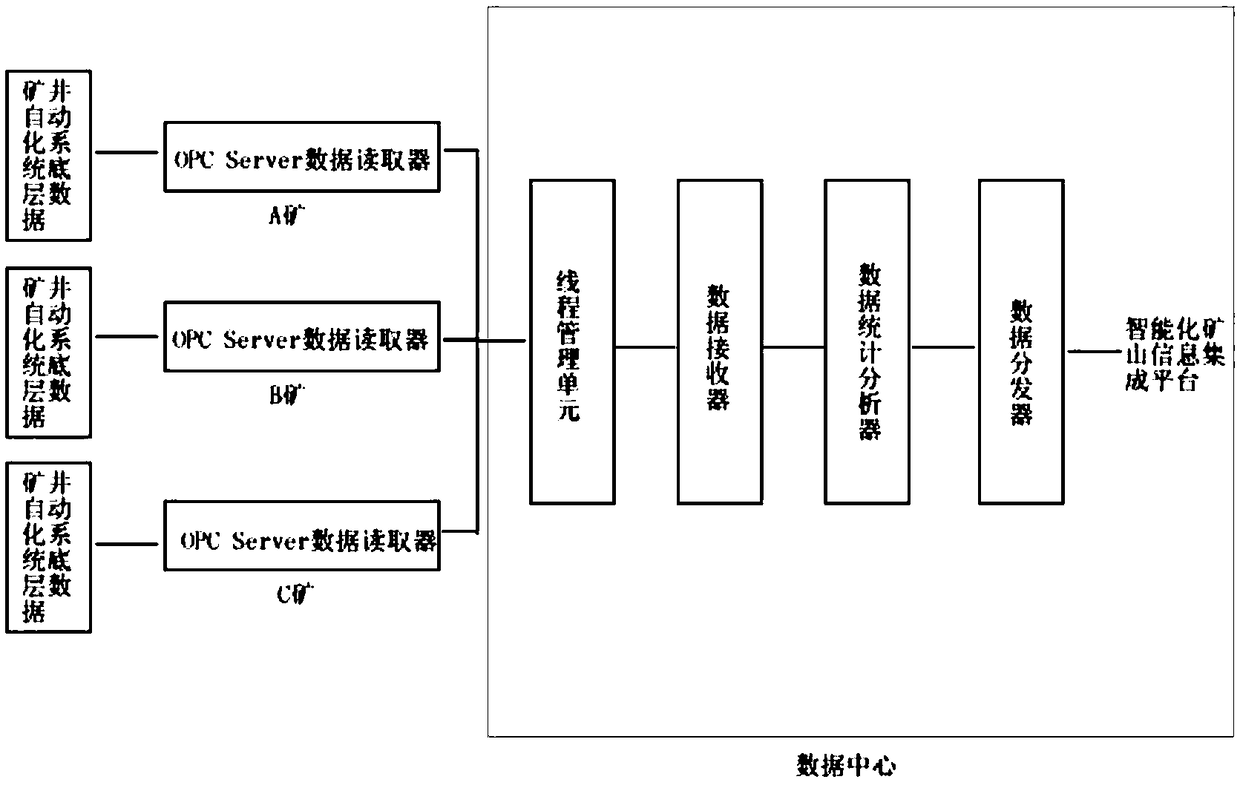

[0060] figure 1 Shown is the structural block diagram of the ZM-1 mine automation system dynamic data real-time transmission system. The system mainly includes the system including OPC Server data reader, data receiver, data statistics analyzer, data distributor, etc. The system can be dispatched and used by group companies or mine units, and is mainly used for real-time collection of mine automation systems (mine main transportation monitoring system, mine power supply monitoring system, mine ventilator monitoring system, coal mining face monitoring system, mine main drainage monitoring system, Mine main hoist monitoring system, etc.), and carry out statistical analysis and display of data.

[0061] 1. OPC Server data reader:

[0062] OPC, as a special COM interface defined by industry standards, is an effective method for mutual data exchange between industrial equipment. At present, the core control equipment PLC of the mine automation system is mainly connected by Linkmas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com