Absorbent body and sanitary article

An absorbent body and absorbent layer technology, applied in the fields of absorbent bodies and sanitary products, can solve the problems of insufficient fixation, hindered liquid permeability, backflow, etc., and achieves the effects of less backflow, excellent diffusivity and absorption speed, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

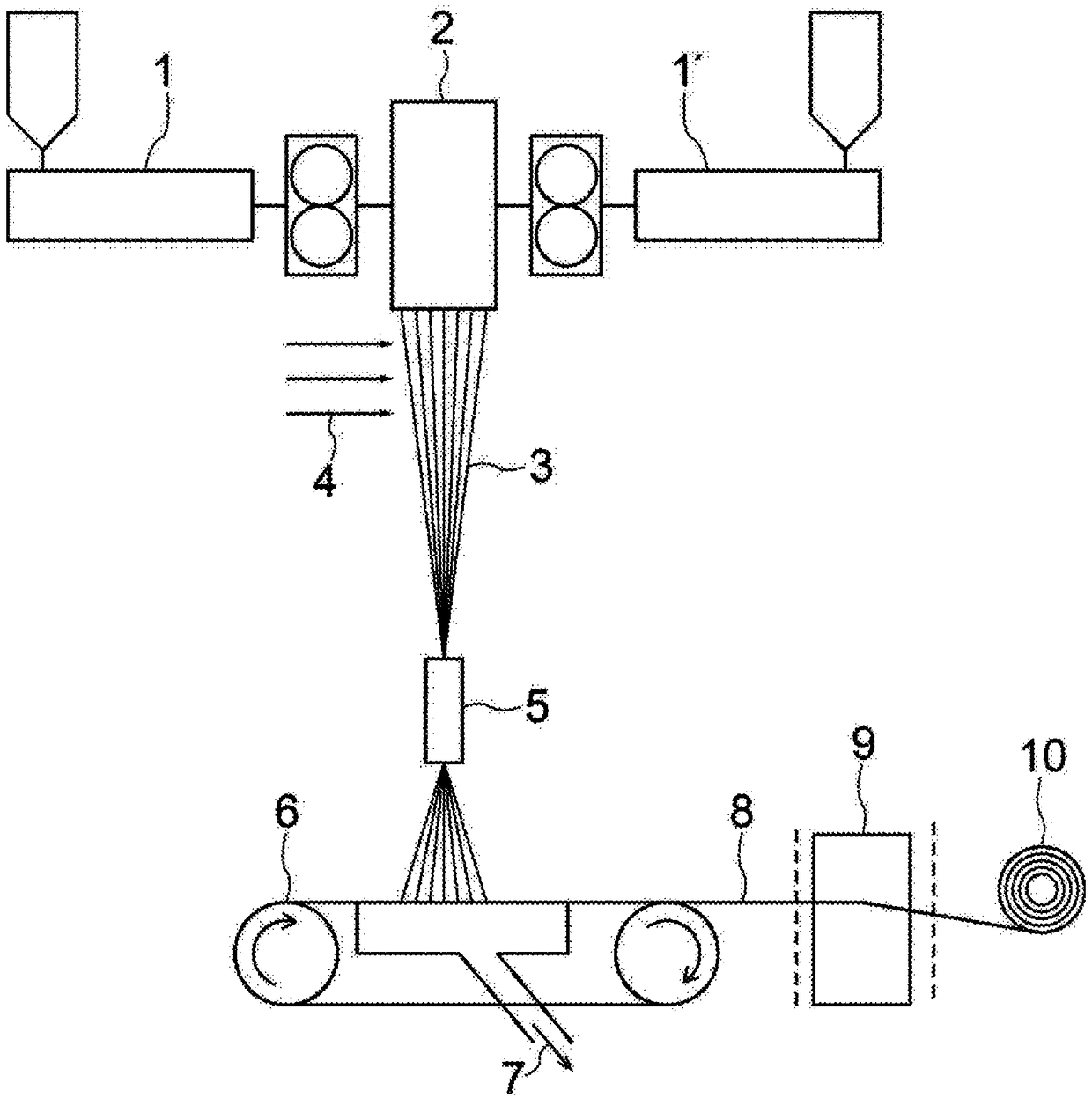

[0206] Prepare figure 2 The shown nonwoven fabric manufacturing apparatus (spunbonding machine, length in the direction (CD direction) perpendicular to the machine flow direction (MD direction) on the collecting surface: 300 mm).

[0207] This nonwoven fabric manufacturing apparatus includes: extruders 1 and 1' for extruding raw materials, a spinning die 2 for spinning the extruded raw materials to produce fibers 3, and a fiber 3 for stretching and discharging. 5, a collector device 6 for making a nonwoven fabric 8 by collecting stretched fibers, a bonding unit 9 for thermally fusing at least a part of the nonwoven fabric 8, and a roll of nonwoven fabric after thermal fusion Take the winder 10. The collector device 6 has a suction unit 7 for efficiently collecting fibers by suction at a lower portion of the surface (collection surface) on which the fibers are collected. In this nonwoven fabric manufacturing apparatus, the fibers 3 obtained from the spinning die 2 are cooled...

Embodiment 2

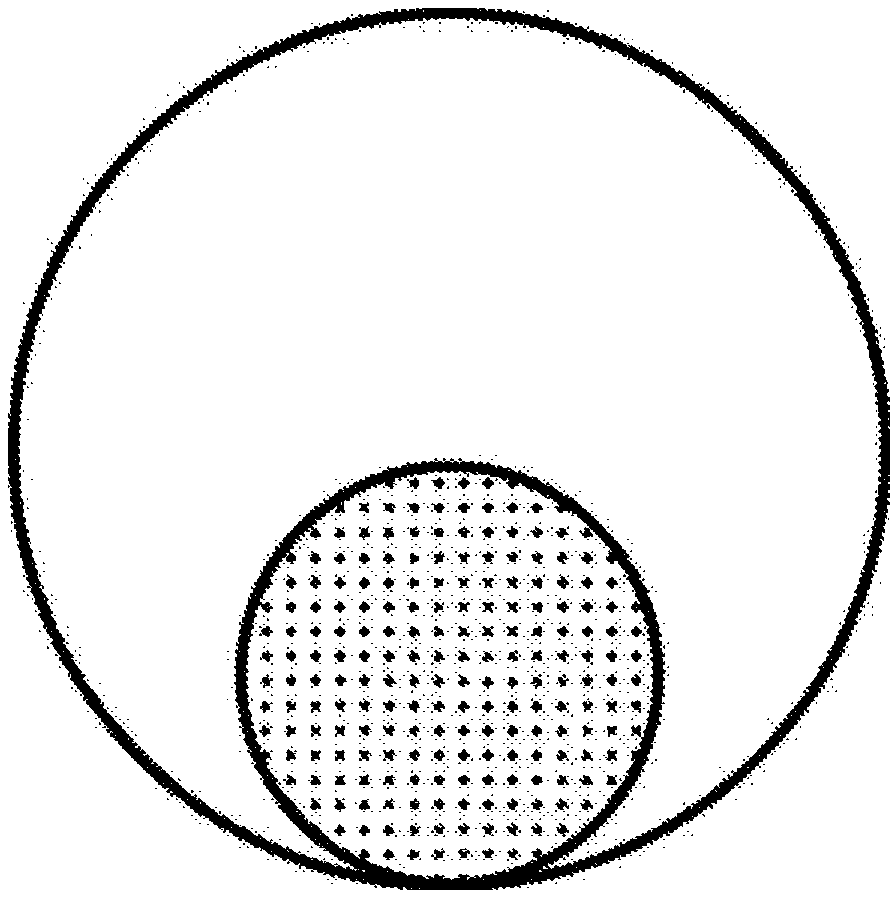

[0220] Change the spinning die 2 to be used to obtain Figure 1B A nonwoven fabric manufacturing apparatus having the same configuration as the nonwoven fabric manufacturing apparatus used in Example 1 was prepared except for the die for spinning fibers (ie, crimped long fibers) having the fiber cross section shown.

[0221] Figure 1B In , the white-painted part and the dotted part represent the resin, respectively.

[0222] Using the nonwoven fabric manufacturing apparatus described above, a spunbonded nonwoven fabric (SB) was produced as follows.

[0223] In Example 2, as the low-melting-point thermoplastic resin A, PP-1 (97 parts by mass) and a glycerin-based hydrophilic agent (3 parts by mass) were used, and as the high-melting-point thermoplastic resin B, a load of 2160 g was used at 230° C. 60 g / 10 minutes of propylene polymer [melting point (Tm) = 157° C.; hereinafter referred to as “PP-2”] (97 parts by mass) and a glycerin-based hydrophilic agent (3 parts by mass). ...

Embodiment 3

[0233] The same operation as in Example 2 was performed except that the amount of SAP was changed to 5.1 g and the measurement of the water absorption rate under load was omitted.

[0234] The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| number of curls | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com