Method of manufacturing of a solar cell and solar cell thus obtained

A technology for solar cells, tunnel dielectrics, used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

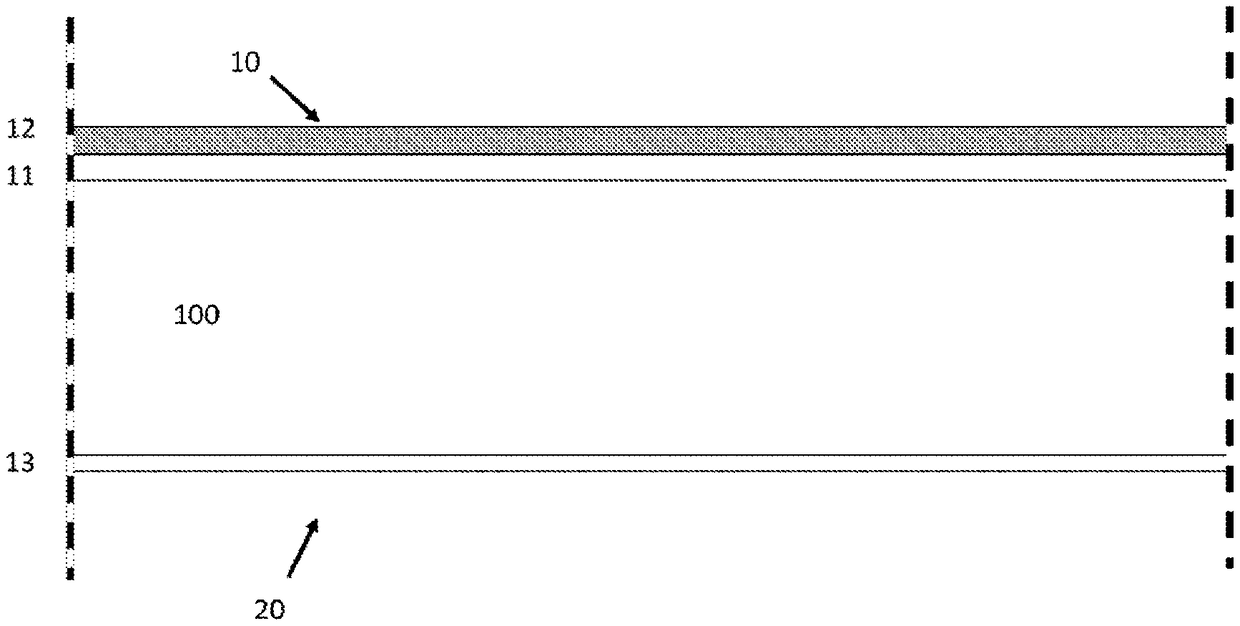

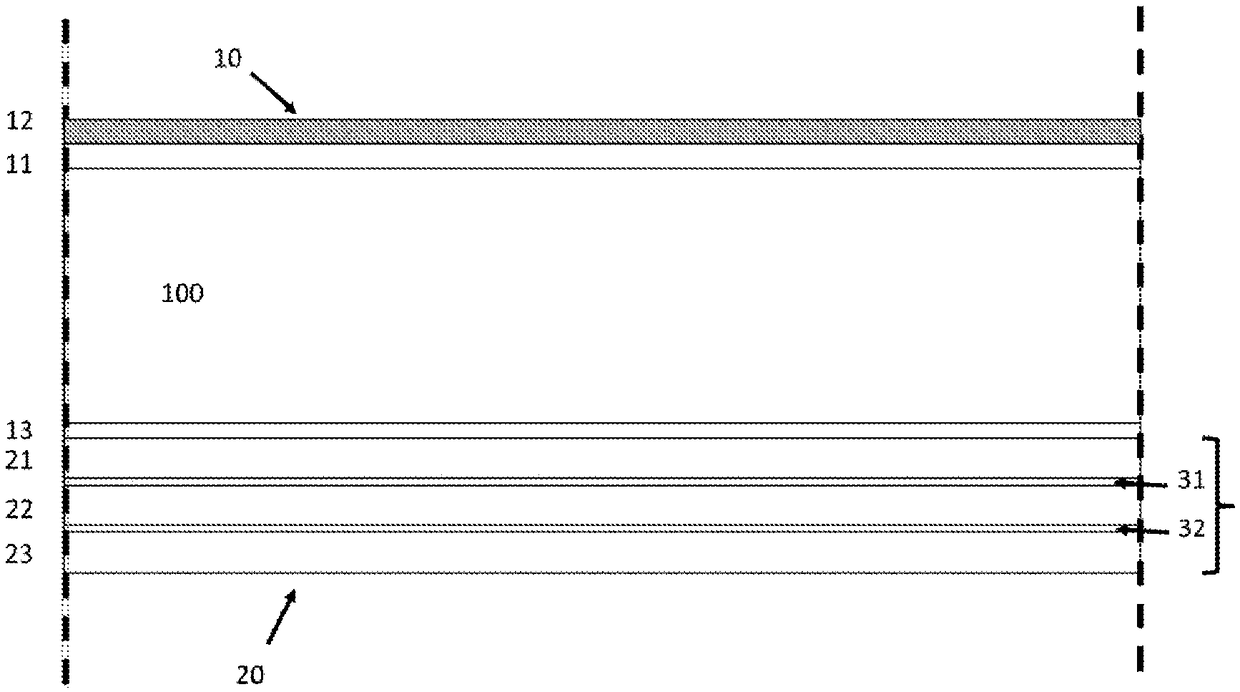

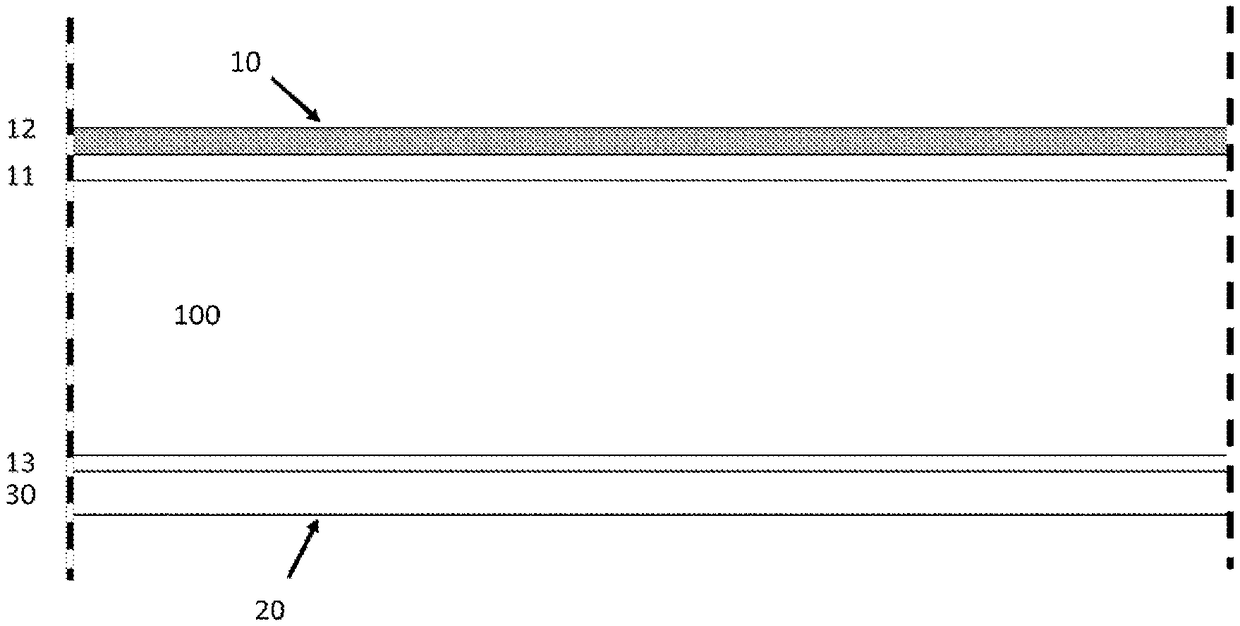

[0091] utensils such as Figure 1C and Figure 1D The test structure for the configuration shown in Complete Preliminary Results. A monocrystalline silicon substrate is used which is doped n-type in a manner conventional to the skilled person. More than one substrate is provided into the reaction chamber of the LPCVD apparatus. The substrate is then processed according to the invention. A tunnel dielectric with a thickness of 1.5 nm was applied by thermal oxidation. Thereafter, a multilayer stack of silicon layers and boron dopant layers is applied. The multilayer stack starts and ends with silicon layers. The total number of boron dopant layers is nine. The total thickness of the multilayer stack is about 400 nm, which is evenly distributed over the 10 polysilicon layers. The boron dopant layer is relatively thin. No protection is applied so that the multilayer stack grows in the same way on both sides of the silicon substrate. This is followed by annealing.

[0092...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com