Laser bars having trenches

A technology of laser rods and grooves, which is applied in the field of laser rods, can solve problems such as fractures and achieve the effect of avoiding electrical short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

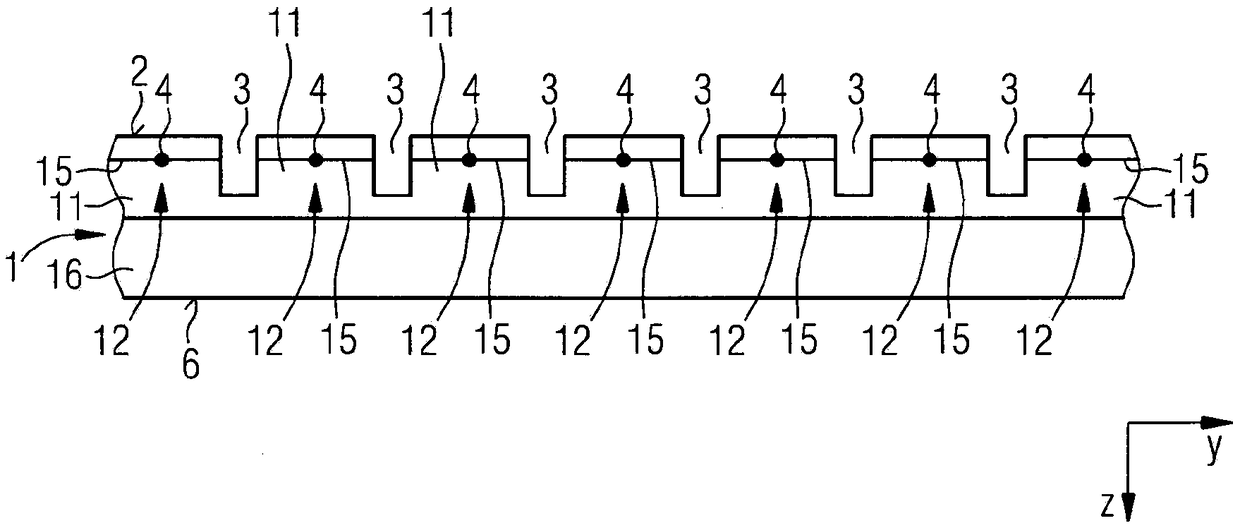

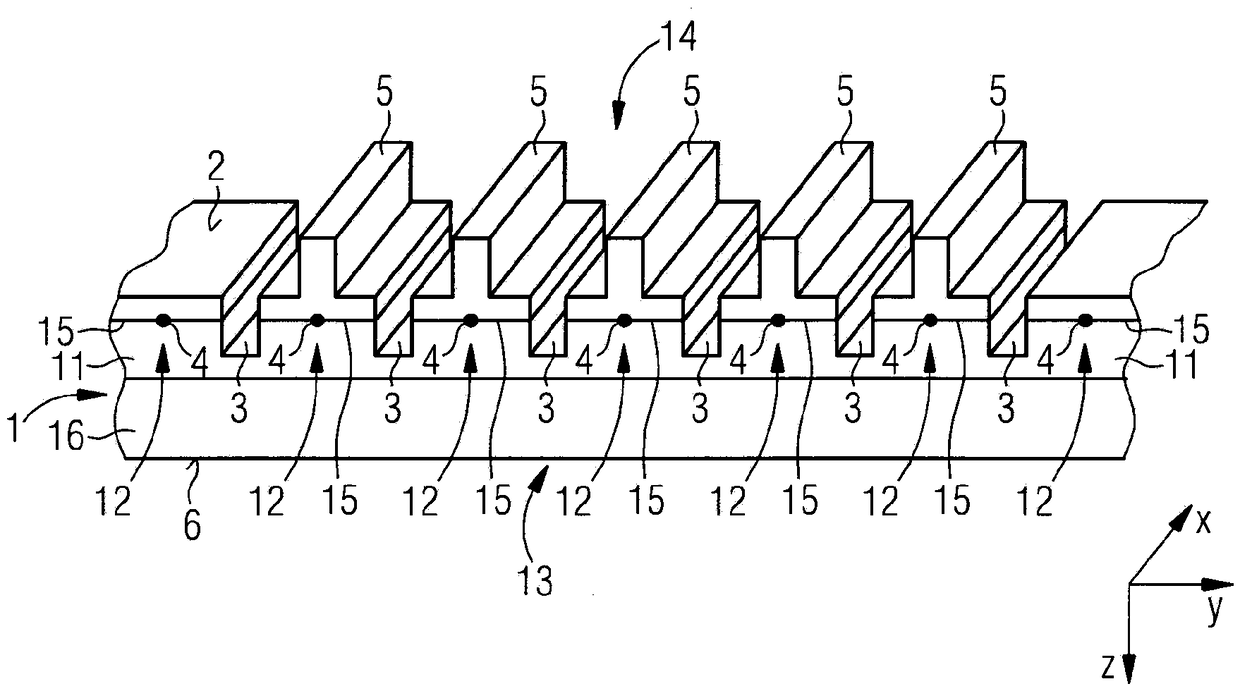

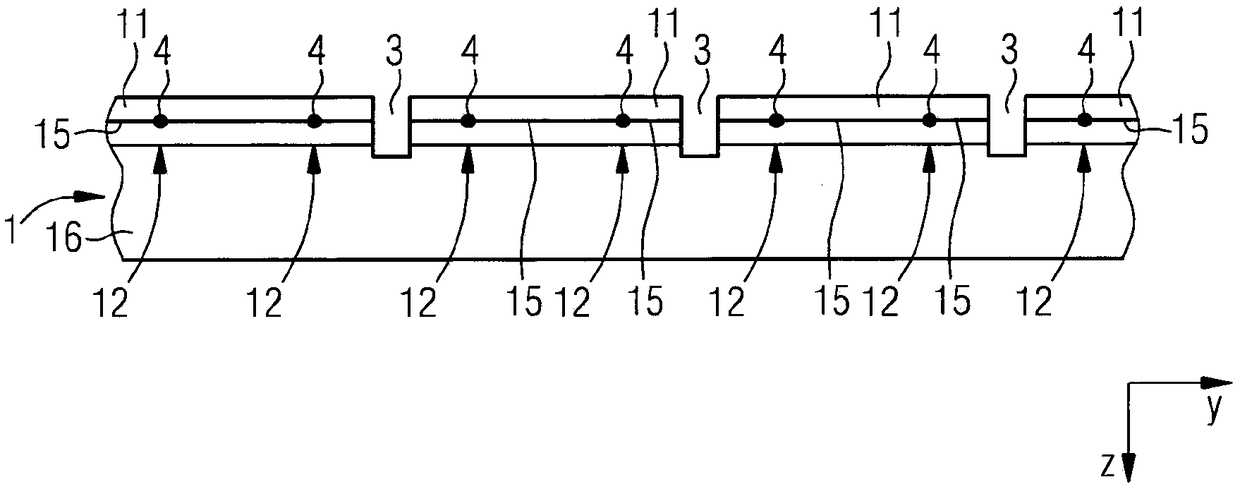

[0035] figure 1 A schematic cross-sectional view of the laser bar 1 is shown. The laser bar 1 has grooves 3 on the first side 2 . The grooves 3 are oriented along the x-axis perpendicular to the drawing plane. The grooves 3 extend to a predetermined depth in the z-axis. Furthermore, the grooves 3 have a predetermined width in the y-axis. The width of the trenches 3 is in the range of 1 μm to 100 μm, preferably 50 μm. The depth of the trenches 3 is in the range of 0.1 μm to 10 μm, preferably 5 μm. In the upper region, the laser rod 1 has a semiconductor layer 11 with a plurality of layers, which is arranged in the xy plane and has an active region 15 for generating electromagnetic radiation. The semiconductor layer 11 is arranged on the substrate 16 . Depending on the chosen embodiment, the trenches 3 can lead under the active area 15 of the semiconductor layer 11 . Furthermore, the grooves 3 can be guided into the base plate 16 . Depending on the chosen embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com