Integrated oriented vacuum well point pipe

An integrated, well point pipe technology, applied in construction, infrastructure engineering and other directions, can solve the problems of large external environmental impact of the foundation pit, slow construction speed, reduction of groundwater outside the foundation pit, etc., to achieve enhanced stability and resistance to deformation. The effect of reducing the surrounding settlement and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

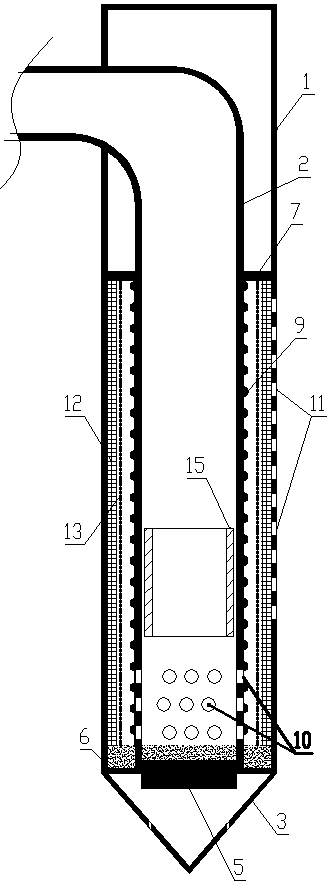

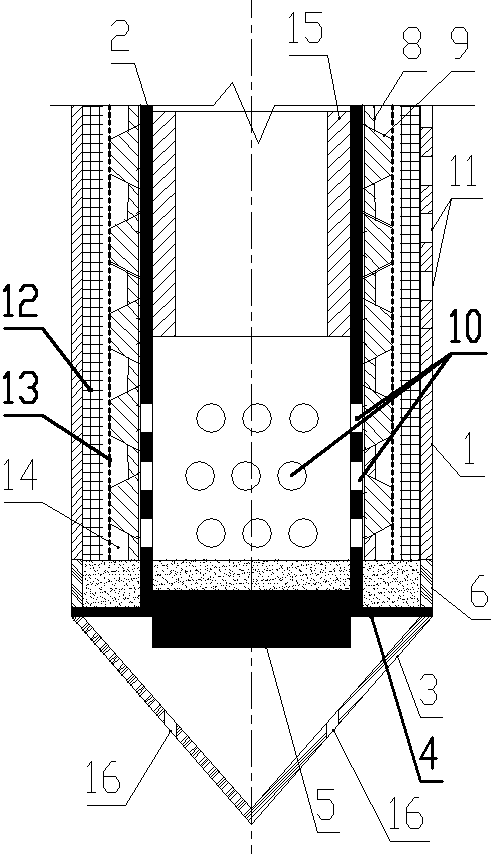

[0051] Such as Figure 1 to Figure 3 As shown, the integrated directional vacuum well point tube of the present invention comprises an outer tube 1, and an inner tube 2 is sleeved inside the outer tube 1, and the outer diameter of the inner tube 2 is smaller than the inner diameter of the outer tube 1; 1 Downward screw connection has a short pipe 6 for enclosing the grit chamber, the axes of the short pipe 6, the inner pipe 2 and the outer pipe 1 are on the same line; the short pipe can be an outer silk pipe or an inner silk pipe, The bottom of the corresponding outer tube 1 is provided with an inner wire or an outer wire. The height of the short tube is 200±2mm;

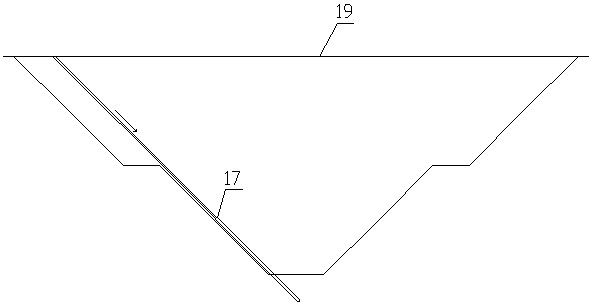

[0052] The short pipe 6 is welded downward with a partition 4; the partition 4 is welded downward with a hollow cone 3, the tip of the hollow cone 3 is set downward, and the side wall of the hollow cone 3 is provided with a number of water outlets 16;

[0053] The bottom end of the inner tube 2 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com