Temperature compensation circuit for direct modulation laser driver

A temperature compensation circuit and laser driver technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of complex circuit design, poor adaptability of temperature compensation circuits, and large occupied area, so as to reduce the complexity and occupied area. , flexible and convenient temperature compensation, improve the effect of accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

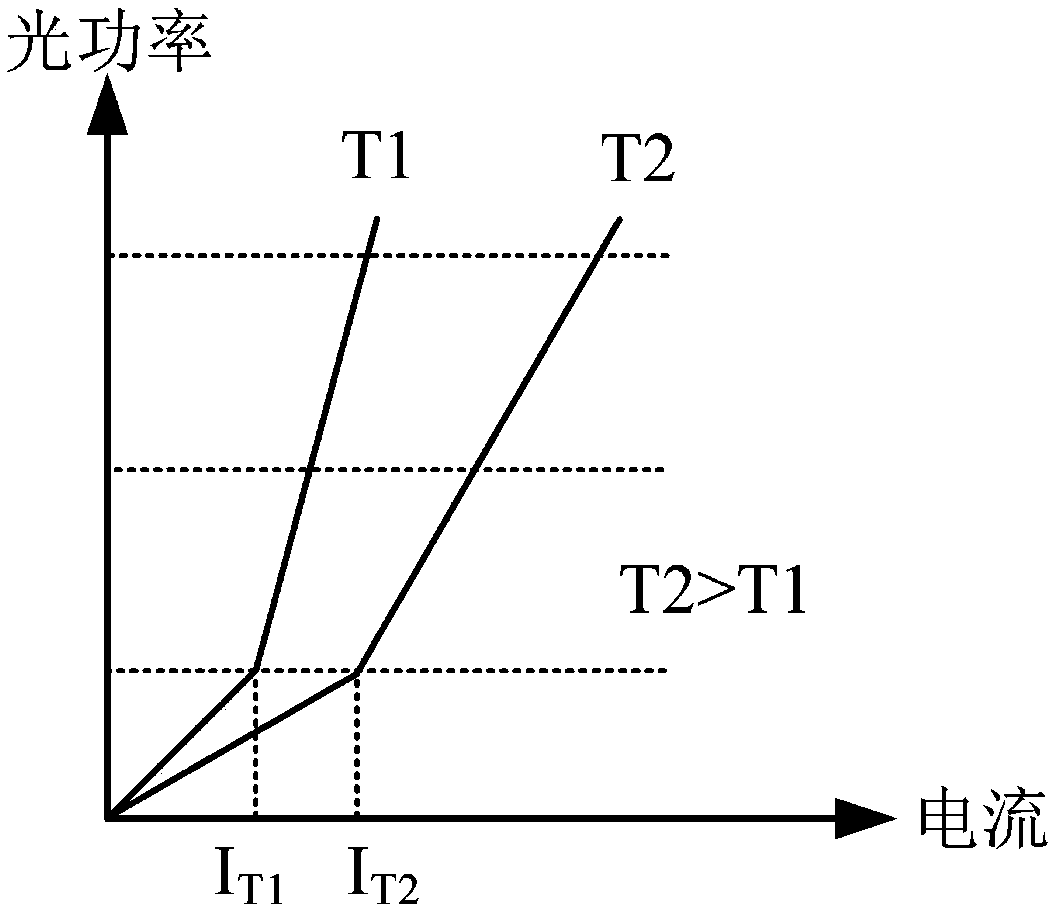

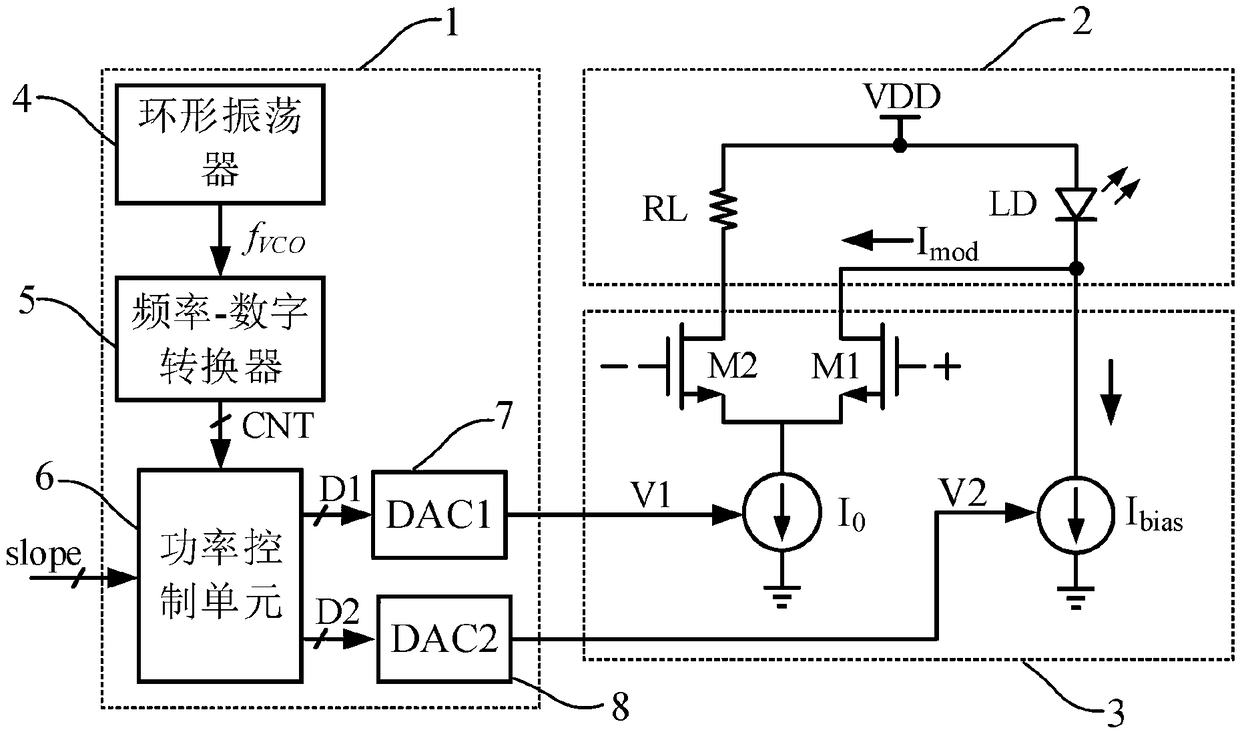

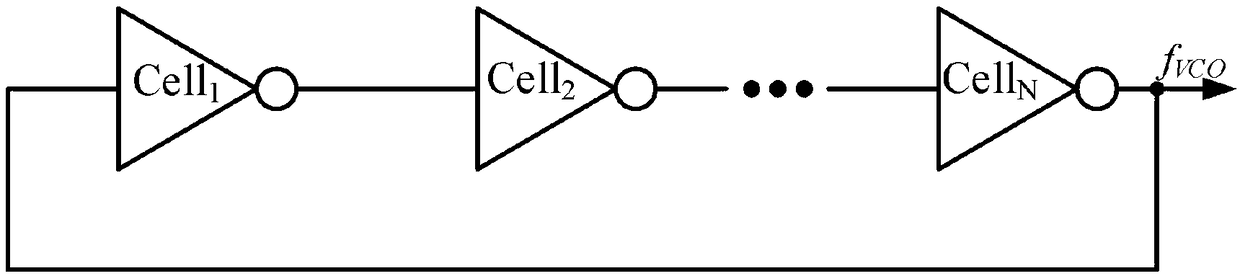

[0031] This embodiment is applied to direct modulation laser drivers, such as figure 2 As shown, it includes a temperature compensation circuit 1 applied to a direct modulation laser driver, a laser diode (or laser) and a matching load circuit 2 , and a laser driver current output module 3 . Temperature compensation circuit 1 generates temperature compensation voltage V1 and temperature compensation voltage V2, which are respectively used to control the tail current I of the laser driver current output module 0 and bias current I bias . The laser driver current output module 3 uses differential output to drive the laser diode, and controls the tail current source I through the temperature compensation voltage V1 0 , which affects the modulation current I of the laser driver mod size, so that the photoelectric conversion efficiency of the laser diode is compensated by the temperature; the bias current I is controlled by the temperature compensation voltage V2 bias , affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com