Method for increasing content of Vc of leaf vegetables inside plant factory

A technology for leafy vegetables and vegetables, applied to the field of increasing the Vc content of leafy vegetables in plant factories, can solve the problems of restricting popularization and application, low comprehensive income, and high operating costs, and achieve high safety, low calorific value, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

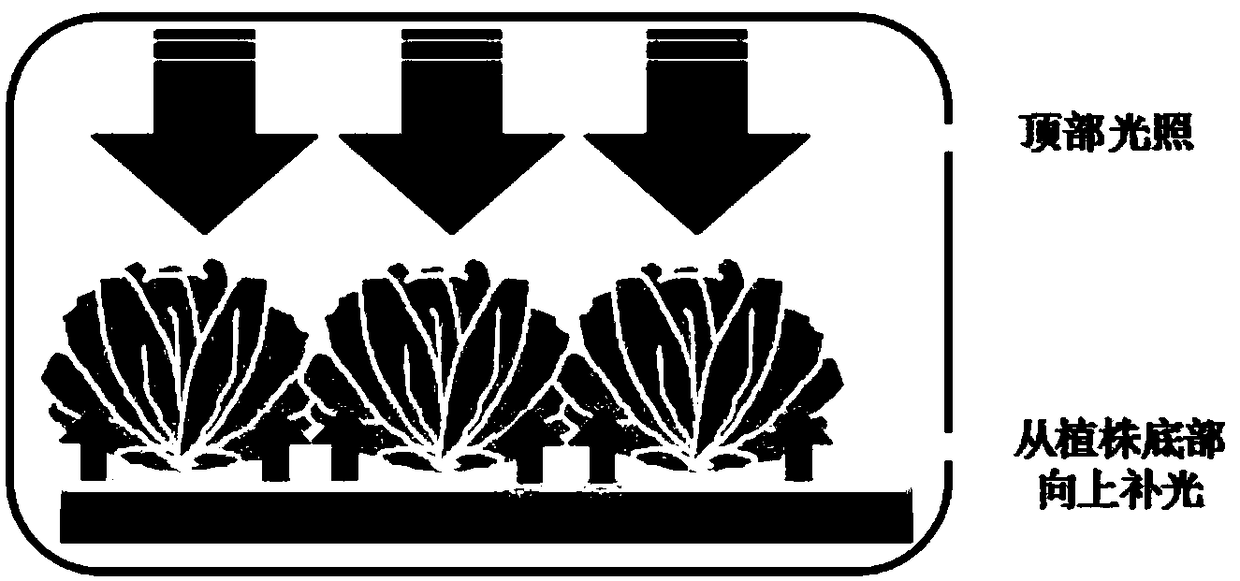

Method used

Image

Examples

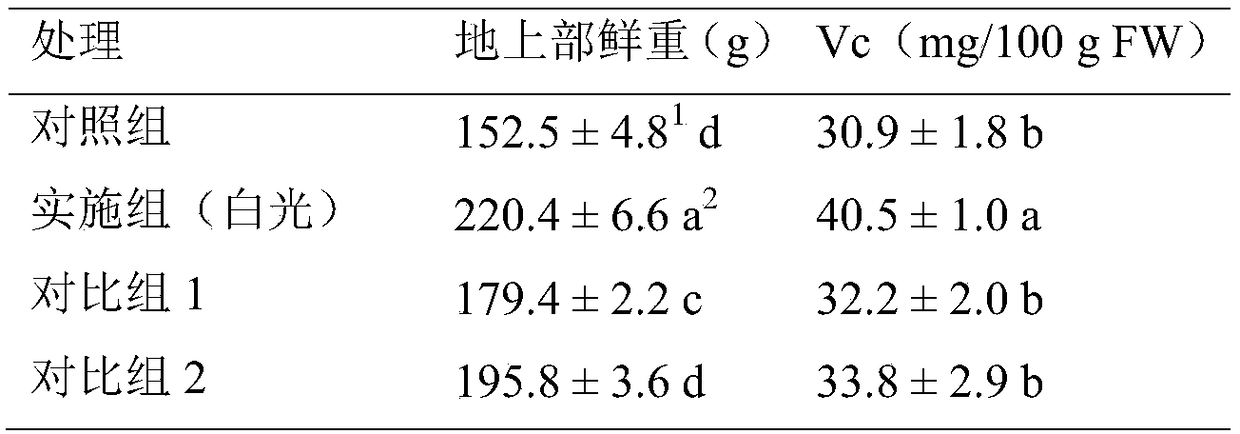

Embodiment 1

[0025] (1) Soak the green leaf lettuce seeds to accelerate germination, sow them in 300-hole seedling trays containing sponge blocks, and place them in a seedling cultivation room for cultivation. The ambient temperature is 20-22°C, the relative humidity is 60-70%, CO 2 The concentration is 380~420μmol·mol -1 , the light intensity is 340~360μmol·m -2 ·s -1 , the light time is 12h·d -1 , the light source is a cold fluorescent lamp.

[0026] (2) After 3 weeks of seedling cultivation, select seedlings with consistent growth and transplant them on the three-dimensional cultivation rack of the artificial light utilization type plant factory, the ambient temperature is 25 / 20°C (day / night), the relative humidity is 60-70%, CO 2 The concentration is 800~1000μmol·mol -1 , with an illumination intensity of 200 μmol m -2 ·s -1 , the light time is 16h·d -1 , the light source is white LED. The nutrient solution is 1 / 2 times the Japanese garden test formula nutrient solution, using ...

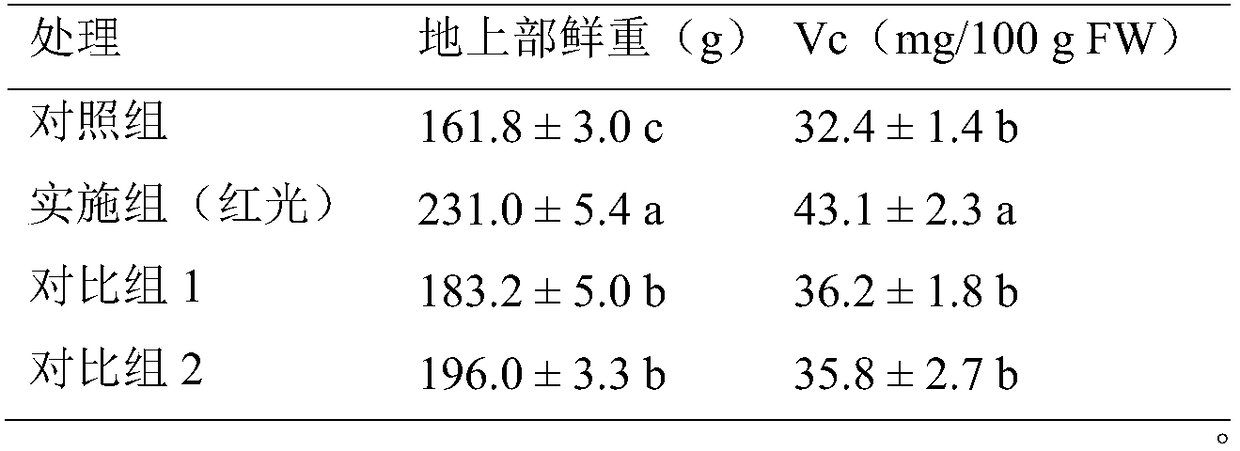

Embodiment 2

[0034] (1) Soak the romaine lettuce seeds to accelerate germination, sow them in 300-hole seedling trays containing sponge blocks, and place them in a seedling cultivation room for cultivation. The ambient temperature is 20-22°C, the relative humidity is 60-70%, CO 2 The concentration is 380~420μmol·mol -1 , the light intensity is 340~360μmol·m -2 ·s -1 , the light time is 12h·d -1 , the light source is a cold fluorescent lamp.

[0035] (2) After 3 weeks of seedling cultivation, select seedlings with consistent growth and transplant them on the three-dimensional cultivation rack of the artificial light utilization type plant factory, the ambient temperature is 25 / 20°C (day / night), the relative humidity is 60-70%, CO 2 The concentration is 800~1000μmol·mol -1 , with an illumination intensity of 200 μmol m -2 ·s -1 , the light time is 16h·d -1 , the light source is white LED. The nutrient solution is 1 / 2 times the Japanese garden test formula nutrient solution, using a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com