An inflammable and explosive dust absorption and dedusting system

A dust removal system and dust absorption technology, applied in the field of dust removal, flammable and explosive metal dust treatment systems, can solve the problems of unable to automatically detect the dust removal effect, easy to induce explosion equipment, etc., to achieve convenient installation and maintenance, small space occupation, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

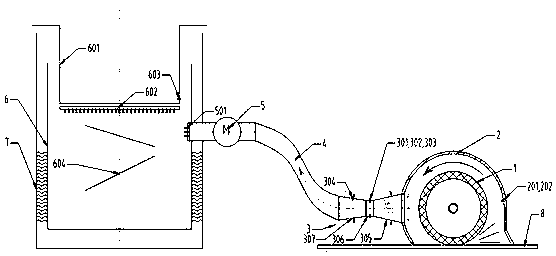

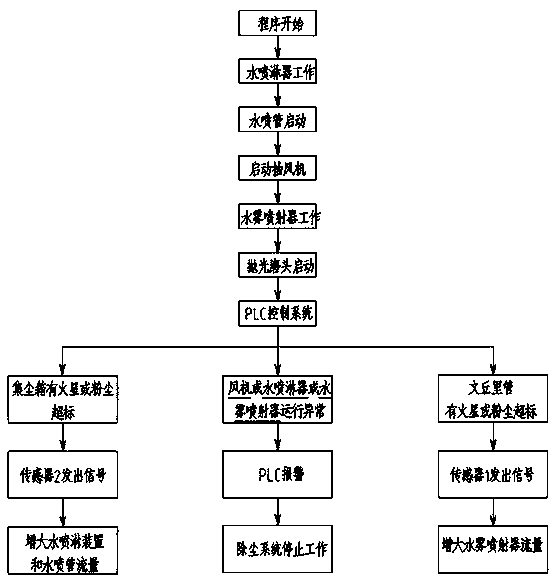

[0024] As shown in the figure, the specific implementation method is as follows:

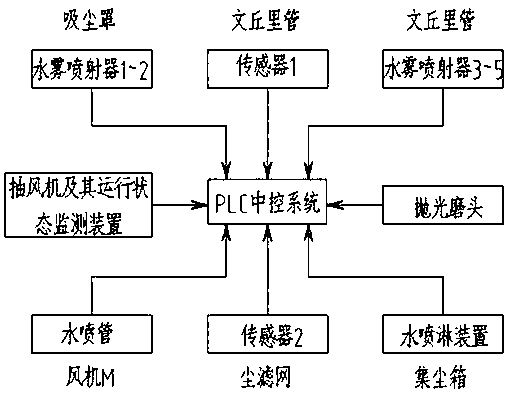

[0025] An inflammable and explosive dust absorption and dust removal system, including a dust collection cover 2 covering the polishing grinding head and a PLC central control system that controls the operation of the entire system. The dust collection cover 2 wraps the polishing grinding head 1 inside, and The titanium steel, titanium plate, aluminum plate, etc. to be polished form a closed negative pressure space, which can completely absorb the dust and sparks generated by polishing in the dust collection cover 2, and the dust collection cover 2 is close to the polishing spark splash Two first water mist injectors are installed on the shooting end, respectively the first water mist injector I201 and the first water mist injector II202, and the other end of the dust collection hood 2 is connected with a Venturi tube 3, Venturi tube 3 comprises constriction section 305, throat 306 and diffusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com