Titanium alloy with osteoinductive activity for bone fixing apparatus

A technology for fixation devices and titanium alloys, applied in the field of titanium alloys for bone fixation devices, can solve the problems of unresolved wear resistance, lack of osteoinductive activity, and unguaranteed bonding strength, etc., to achieve improved thermodynamic stability, good bone Effect of inducing activity and enhancing bone growth activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

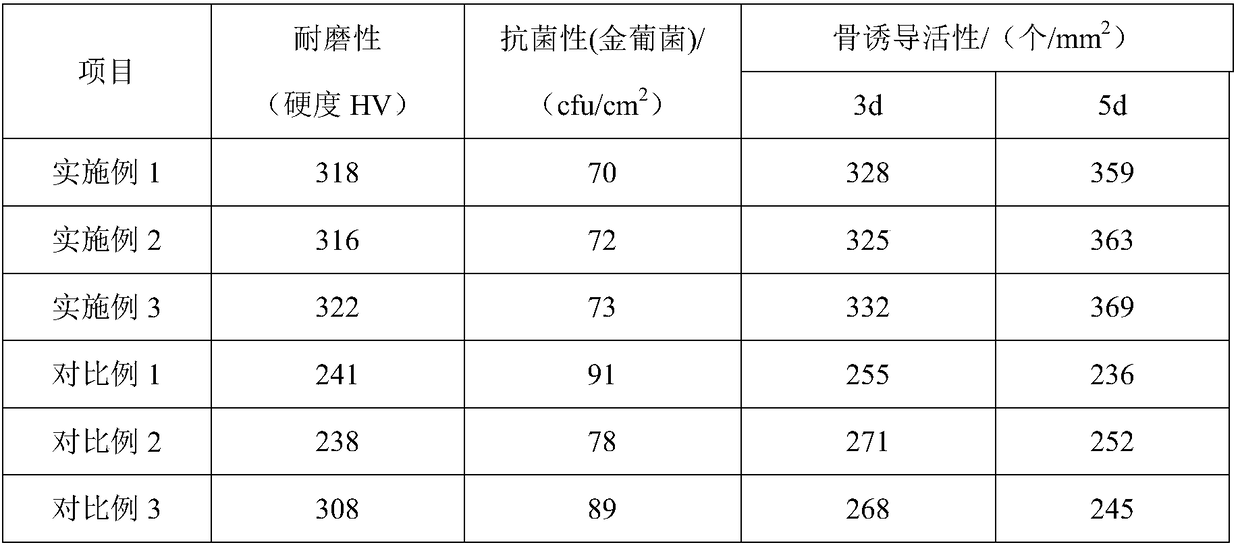

Examples

Embodiment 1

[0018] 1) Ingredients: by mass percentage: Zn 4.5%, Fe 3%, Mo 0.75%, Sr 0.5%, Se 0.5%, Mn 0.5%, Cu0.3%, nano silver wire 1.8%, ZrO 2 8.2%, K 2 CO 3 0.6%, B 0.7%, Zr 15%, carbon nanotube 0.2%, the balance is Ti;

[0019] 2) Preparation of master alloy: the master alloy has two kinds of I and II; the master alloy I is made of nano-silver wire and ZrO 2 Sintering preparation, the nano-silver wire diameter is 80nm, the ZrO 2 The particle size of the particles is 0.3 μm, and they are sintered in a vacuum induction furnace at a temperature of 600-660°C and a time of 30-45 minutes; the master alloy II is composed of K 2 CO 3 , B, Zr, and carbon nanotubes, smelted in a vacuum induction furnace at a temperature of 1800-1850°C, and poured into a graphite mold after holding for 2 hours to obtain an alloy ingot;

[0020] 3) Smelting and casting: Put Zn, Fe, Mo, Sr, Se, Mn, Cu, master alloy I, master alloy II, Ti and other raw materials into the non-consumable electrode water-cooled...

Embodiment 2

[0025] 1) Ingredients: by mass percentage: Zn 5%, Fe 3.5%, Mo 0.8%, Sr 0.6%, Se 0.5%, Mn 0.6%, Cu 0.35%, nano silver wire 1.8%, ZrO 2 8.2%, K 2 CO 3 0.6%, B 0.7%, Zr 15%, carbon nanotube 0.25%, the balance is Ti;

[0026] 2) Preparation of master alloy: the master alloy has two kinds of I and II; the master alloy I is made of nano-silver wire and ZrO 2 Sintering preparation, the nano-silver wire diameter is 90nm, the ZrO 2 The particle size of the particles is 0.35 μm, which is sintered in a vacuum induction furnace at a temperature of 600-660°C and a time of 30-45 minutes; the master alloy II is composed of K 2 CO 3 , B, Zr, and carbon nanotubes, smelted in a vacuum induction furnace at a temperature of 1800-1850°C, and poured into a graphite mold after holding for 2 hours to obtain an alloy ingot;

[0027] 3) Smelting and casting: Put Zn, Fe, Mo, Sr, Se, Mn, Cu, master alloy I, master alloy II, Ti and other raw materials into the non-consumable electrode water-cooled ...

Embodiment 3

[0032] 1) Ingredients: by mass percentage: Zn 5.5%, Fe 4.8%, Mo 0.8%, Sr 0.5%, Se 0.5%, Mn 0.5%, Cu0.3%, nano silver wire 1.8%, ZrO 2 8.2%, K 2 CO 3 0.6%, B 0.9%, Zr 18%, carbon nanotube 0.4%, the balance is Ti;

[0033]2) Preparation of master alloy: the master alloy has two kinds of I and II; the master alloy I is made of nano-silver wire and ZrO 2 Sintering preparation, the nano-silver wire diameter is 100nm, the ZrO 2 The particle size of the particles is 0.5 μm, which is sintered in a vacuum induction furnace at a temperature of 600-660°C and a time of 30-45 minutes; the master alloy II is composed of K 2 CO 3 , B, Zr, and carbon nanotubes, smelted in a vacuum induction furnace at a temperature of 1800-1850°C, and poured into a graphite mold after holding for 2 hours to obtain an alloy ingot;

[0034] 3) Melting and casting: put Ca, Zn, Fe, Mo, Sr, Se, Mn, Cu, master alloy I, master alloy II, Ti and other raw materials into the non-consumable electrode water-cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com