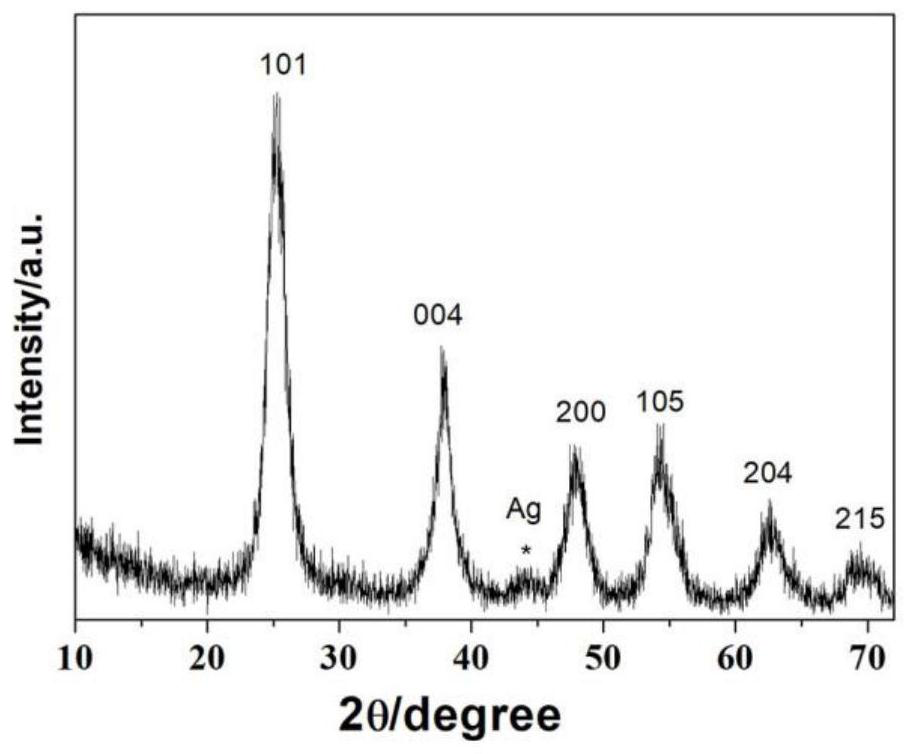

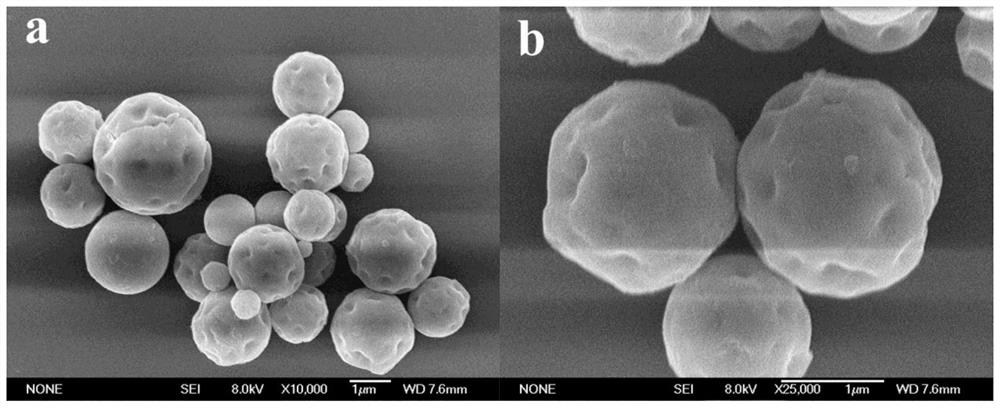

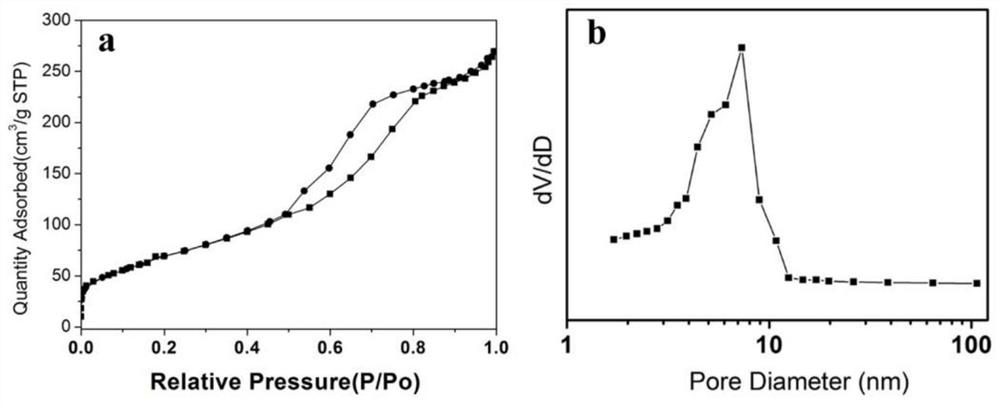

a golf ball-shaped ag/tio 2 Composite porous microsphere and preparation method thereof

A technology of porous microspheres and golf balls, applied in the direction of microsphere preparation, catalyst activation/preparation, microcapsule preparation, etc., can solve the problems of complex process, high cost, and difficult to control shape, and achieve simple process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Weigh 60 g of titanium oxalic acid titanium oxalate to dissolve in 1800 ml of deionized water, 0.8 g of silver nitrate is added to 200 ml of deionized water, and the spray dryer is sprayed at 200 ° C to prepare Ag / TiO. 2 Pretty microspheres;

[0014] (2) When the resulting precursor powder obtained by step (1) is heated to 550 ° C from 10 ° C / min, after cooling for 4 h, it is washed three times with water and ethanol, drying at 60 ° C for 2 h, and prepared golf-shaped Ag / TiO 2 Composite porous microspheres.

Embodiment 2

[0016] (1) Weigh 60 g of titanium oxalic acid titanium oxalate dissolve in 1800 ml of deionized water, 1.6 g of silver nitrate is added to 200 ml of deionized water, spray dry by spray dryer at 200 ° C, preparing Ag / TiO 2 Pretty microspheres;

[0017] (2) When the resulting precursor powder obtained by step (1) is heated to 550 ° C from 10 ° C / min, after cooling for 4 h, it is washed three times with water and ethanol, drying at 60 ° C for 2 h, and prepared golf-shaped Ag / TiO 2 Composite porous microspheres.

Embodiment 3

[0019] (2) Weigh 60 g of titanium oxalic acid titanium oxalate dissolved in 1800 ml of deionized water, 0.4 g of silver nitrate was added to 200 ml of deionized water, spray dry by spray dryer at 200 ° C, prepared Ag / TiO 2 Pretty microspheres;

[0020] (2) When the resulting precursor powder obtained by step (1) is heated to 550 ° C from 10 ° C / min, after cooling for 4 h, it is washed three times with water and ethanol, drying at 60 ° C for 2 h, and prepared golf-shaped Ag / TiO 2 Composite porous microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com