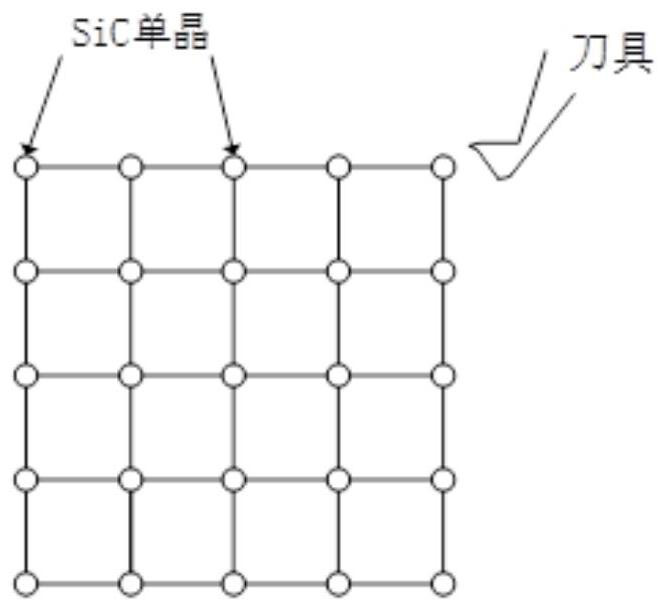

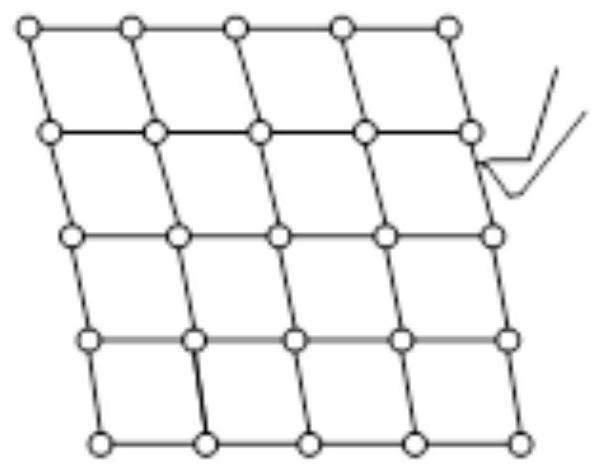

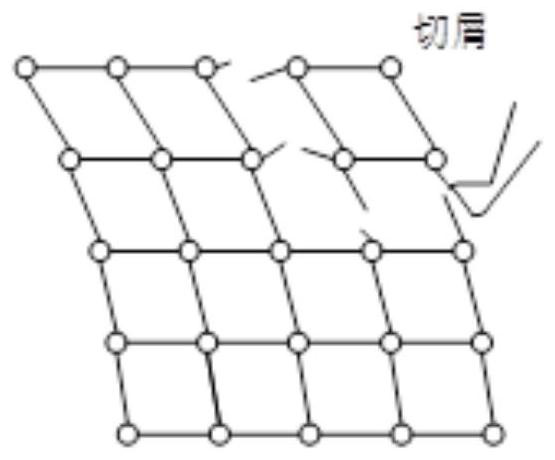

Ion implantation surface modification and nanoscale polishing methods for single crystal SiC

A technology of ion implantation and surface modification, applied in the field of ultra-precision machining of brittle materials, can solve problems such as material deformation, achieve the effect of reducing hardness and brittleness, taking into account work efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, measure the roughness of the surface of the wafer to be polished after grinding, the measured surface roughness of the wafer is 30nm, and determine the depth of ion implantation according to the roughness of the wafer surface after grinding;

[0035] Step 2, ion implantation on the surface of the SiC wafer,

[0036] After determining the selected ion implanter for operation, Al ions are selected for implantation. According to the proportional relationship between the wafer surface roughness measured in step 1 and the ion implantation depth and ion implantation energy value, the ion implantation depth corresponding to the wafer surface roughness is selected to be 30nm. And sequentially select 3 groups of energies implanted into wafers with implantation depths of 30nm, 20nm and 10nm respectively;

[0037] Step 3, mechanically remove the wafer surface,

[0038] Place the ion-implanted wafer in a polishing machine to remove the ion-implanted surface layer of the wa...

Embodiment 2

[0040] Step 1, measure the roughness of the wafer surface to be polished after grinding, the measured wafer surface roughness is 50nm, and determine the depth of ion implantation according to the surface roughness of the wafer after grinding;

[0041] Step 2, ion implantation on the surface of the SiC wafer,

[0042] After determining the selected ion implanter for operation, Al ions are selected for implantation. According to the proportional relationship between the wafer surface roughness measured in step 1 and the ion implantation depth and the ion implantation energy value, the ion implantation depth corresponding to the wafer surface roughness is selected to be 50nm. And sequentially select 4 groups of energies implanted into wafers in sequence so that the implantation depths are 50nm, 40nm, 30nm, and 20nm respectively;

[0043] Step 3, mechanically remove the wafer surface,

[0044] Place the ion-implanted wafer in a polishing machine to remove the ion-implanted surfac...

Embodiment 3

[0046] Step 1, measure the roughness of the wafer surface to be polished after grinding, the measured wafer surface roughness is 70nm, and determine the depth of ion implantation according to the surface roughness of the wafer after grinding;

[0047] Step 2, ion implantation on the surface of the SiC wafer,

[0048] After determining the selected ion implanter for operation, Al ions are selected for implantation. According to the proportional relationship between the wafer surface roughness measured in step 1 and the ion implantation depth and ion implantation energy value, the ion implantation depth corresponding to the wafer surface roughness is selected to be 70nm. And sequentially select 4 groups of energies implanted into wafers in sequence so that the implantation depths are 70nm, 50nm, 30nm, and 10nm respectively;

[0049] Step 3, mechanically remove the wafer surface,

[0050] Place the ion-implanted wafer in a polishing machine to remove the ion-implanted surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com