Side impact prevention energy absorption plate for automobile door

A technology for automobile doors and energy-absorbing panels, applied in the direction of doors, vehicle parts, transportation and packaging, etc., can solve the problems of visceral or torso injuries, squeezing of drivers and passengers, personal injury, etc., to protect the body, prevent The effect of oppression and protection of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

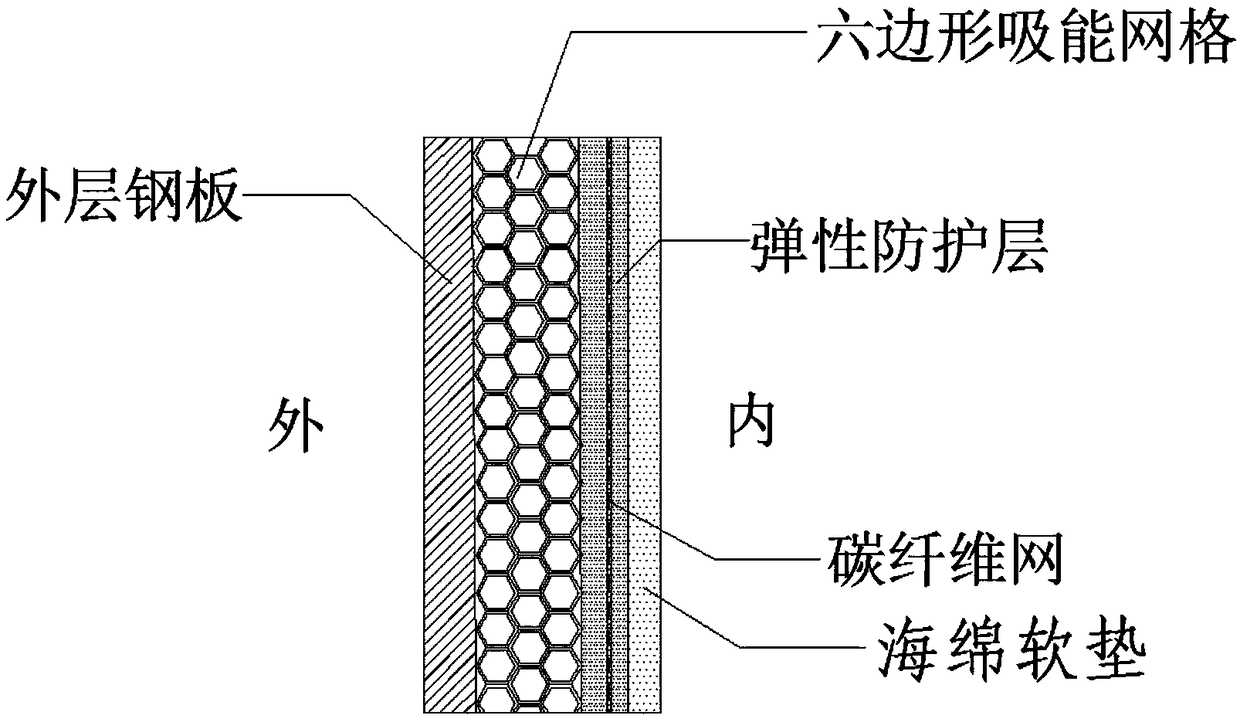

[0032] An anti-side impact energy-absorbing panel for an automobile door, comprising an elastic protection layer from inside to outside, a hexagonal energy-absorbing grid and an outer steel plate, the elastic protection layer is provided with at least one layer of carbon fiber mesh, the elastic A sponge cushion is adhered to the inner side of the protective layer, the thickness of the sponge cushion is 6mm, the thickness of the elastic protective layer is 3mm, the thickness of the hexagonal energy-absorbing grid is 15mm, and the thickness of the outer steel plate is 5mm.

[0033] The elastic protective layer is composed of the following parts by weight: 55 parts of polypropylene resin, 43 parts of polyethylene resin, 18 parts of EPDM rubber, 6 parts of 20-30mm carbon fiber, 8 parts of 5-10mm carbon fiber, 1250 mesh weight 15 parts of calcium carbonate, 2 parts of alkylphenol ether carboxylate WNWS-1, 2 parts of modified polyolefin, and 3 parts of other additives.

[0034] The ...

Embodiment 2

[0042] An automobile door anti-side impact energy-absorbing panel, comprising an elastic protection layer from inside to outside, a hexagonal energy-absorbing grid and an outer steel plate, the elastic protection layer is provided with 2 layers of carbon fiber nets, and the elastic protection layer A sponge cushion is attached to the inner side of the layer, the thickness of the sponge cushion is 5mm, the thickness of the elastic protective layer is 2mm, the thickness of the hexagonal energy-absorbing grid is 10mm, and the thickness of the outer steel plate is 3mm.

[0043] The elastic protective layer is composed of the following parts by weight: 50 parts of polypropylene resin, 40 parts of polyethylene resin, 15 parts of EPDM rubber, 5 parts of 20-30mm carbon fiber, 5 parts of 5-10mm carbon fiber, 1250 mesh weight 10 parts of calcium carbonate, 1 part of alkylphenol ether carboxylate WNWS-1, 1 part of modified polyolefin, and 1 part of other additives.

[0044] The preparati...

Embodiment 3

[0052] An anti-side impact energy-absorbing panel for an automobile door, comprising an elastic protection layer from inside to outside, a hexagonal energy-absorbing grid and an outer steel plate, the elastic protection layer is provided with 3 layers of carbon fiber nets, and the elastic protection layer A sponge cushion is attached to the inner side of the layer, the thickness of the sponge cushion is 8mm, the thickness of the elastic protective layer is 5mm, the thickness of the hexagonal energy-absorbing grid is 20mm, and the thickness of the outer steel plate is 6mm.

[0053] The elastic protective layer is composed of the following components in parts by weight: 80 parts of polypropylene resin, 50 parts of polyethylene resin, 20 parts of EPDM rubber, 10 parts of 20-30mm carbon fiber, 10 parts of 5-10mm carbon fiber, 1250 mesh weight 20 parts of calcium carbonate, 5 parts of alkylphenol ether carboxylate WNWS-1, 5 parts of modified polyolefin, and 5 parts of other additive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com