MBBR (Moving Bed Biofilm Reactor) used for electroplating wastewater treatment

A technology of electroplating wastewater and reactors, which is applied in metallurgical wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of scaling at the bottom of the pool, improve treatment capacity and facilitate maintenance , The effect of reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

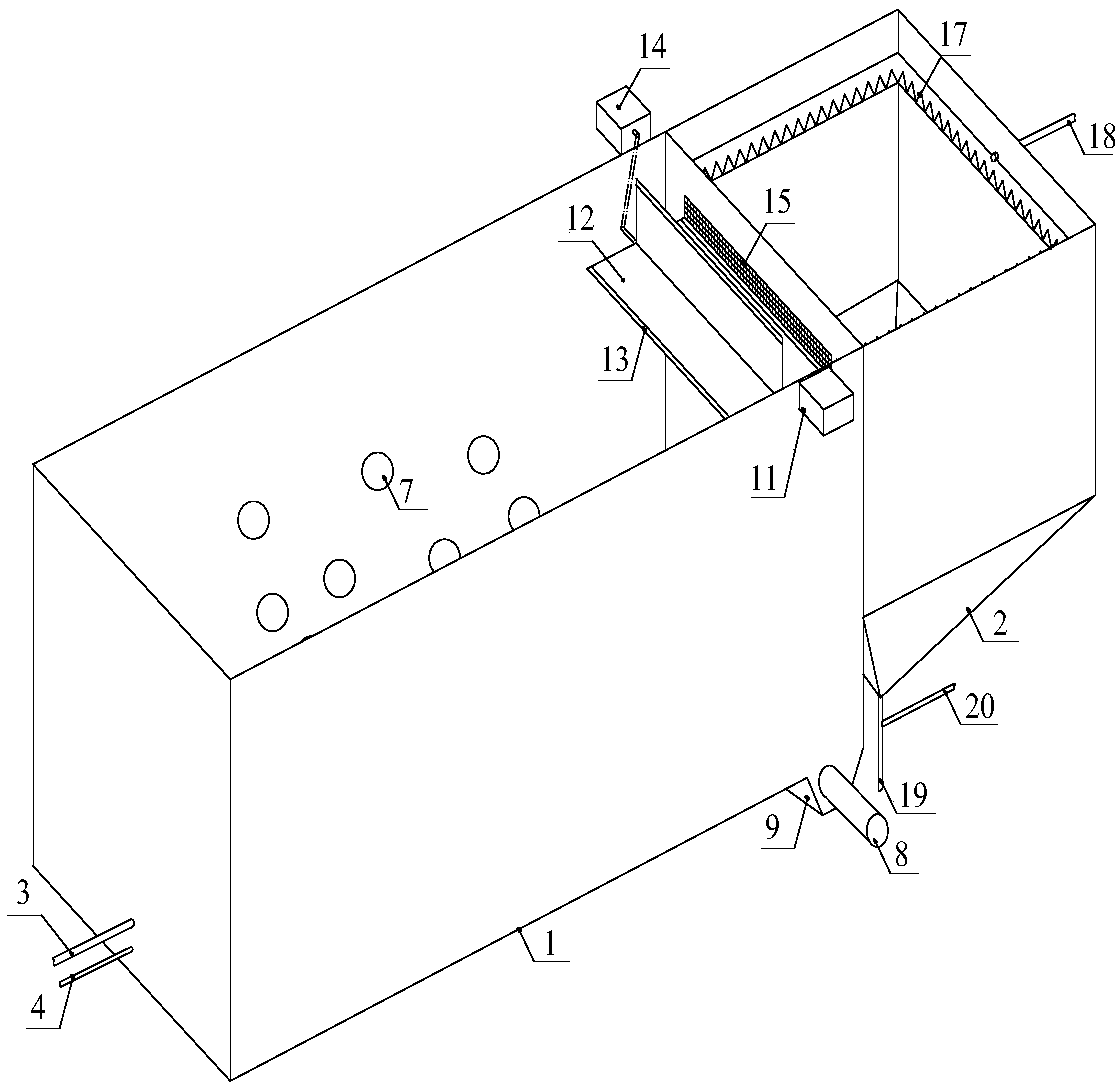

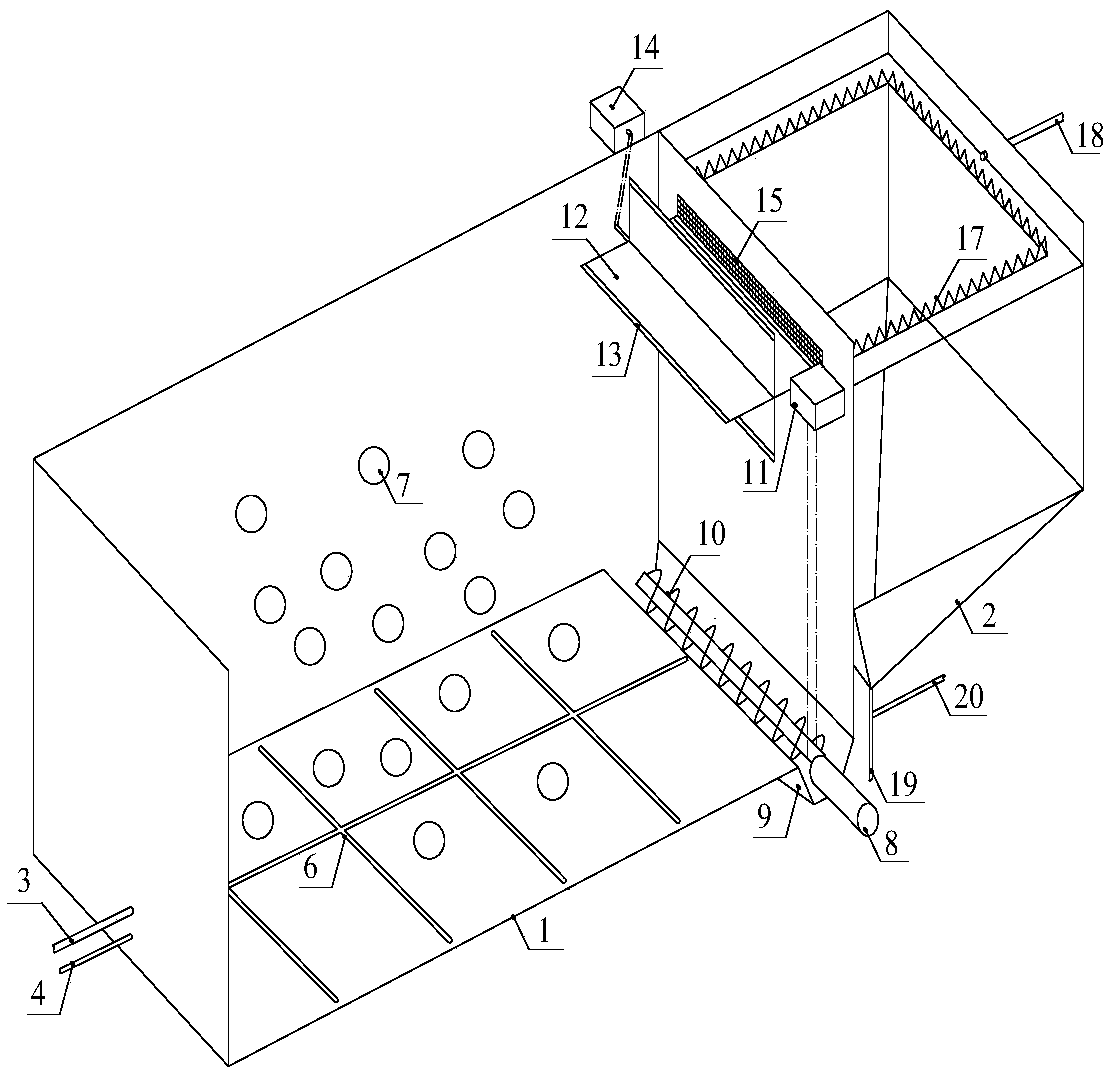

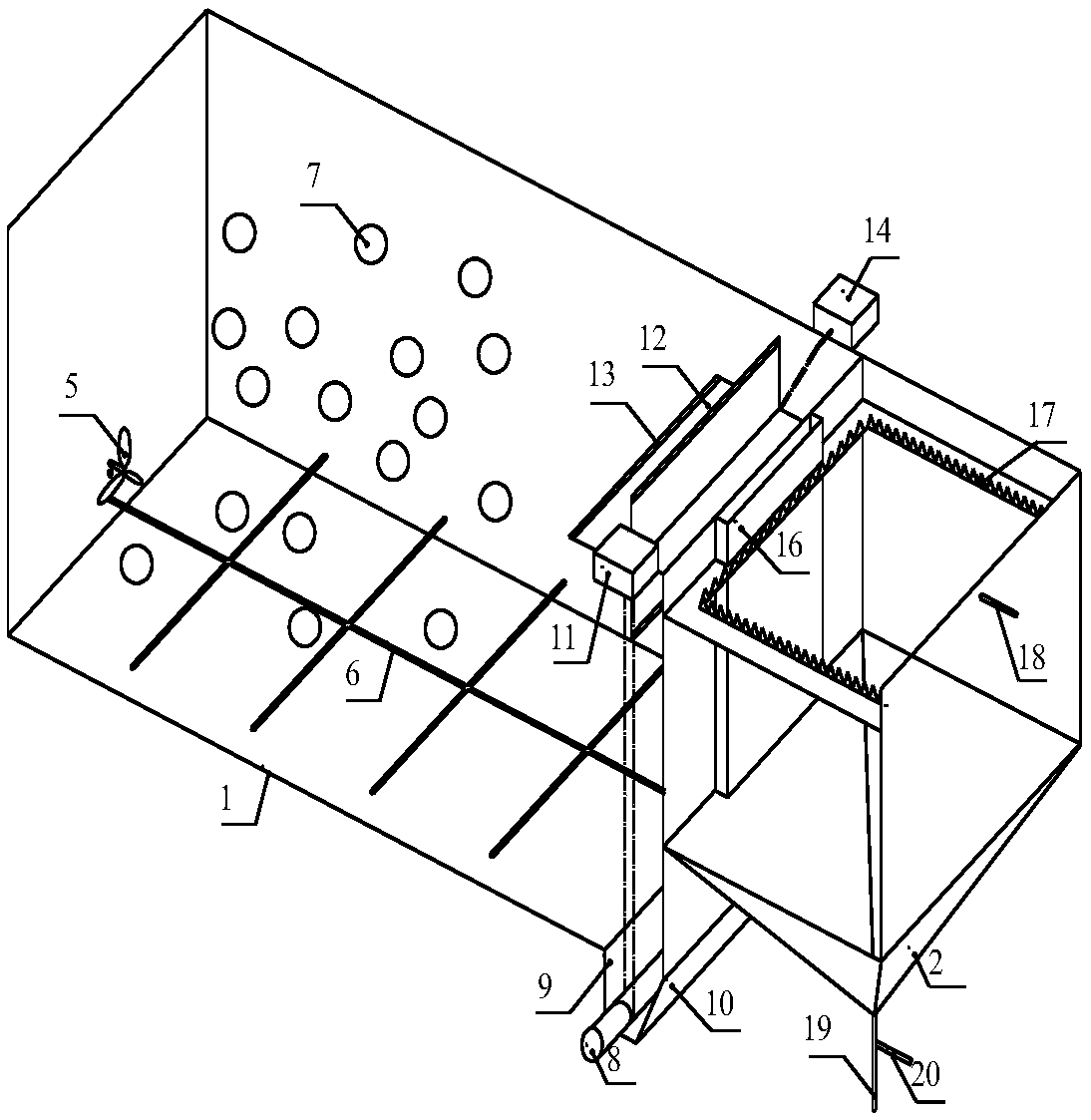

[0024] Such as figure 1 , 2 , 3, an MBBR reactor for electroplating wastewater treatment, including a reaction tank 1 and a sedimentation tank 2. The water inlet end of the bottom of the reaction tank 1 is provided with a water inlet pipe 3, an air inlet pipe 4 and at least one submersible agitator 5, and an aeration pipe 6 and a packing sedimentation ditch 9 with a packing discharge pipe 8 are arranged at the bottom, and a spiral is arranged inside the packing sedimentation ditch 9. Conveyor 10, rotating scraper 12 and screen 15 are provided at the outlet end of the upper part of reaction tank 1, and suspended filler 7 is placed inside reaction tank 1. The water inlet of the sedimentation tank 2 is provided with a diversion tank 16 , an outlet weir 17 and an outlet pipe 18 are provided at the upper part of the tank body, and a sludge discharge pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com