Chitosan chlorogenic acid salt, preparation method and application thereof

A technology of chlorogenic acid salt and chitosan, which is applied in the field of daily chemicals, can solve problems such as failure to meet market requirements, application limitations, and weak biological activity, and achieve the effects of easy promotion, low cost, and improved biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The target compound chitosan chlorogenic acid was synthesized according to the above synthetic route.

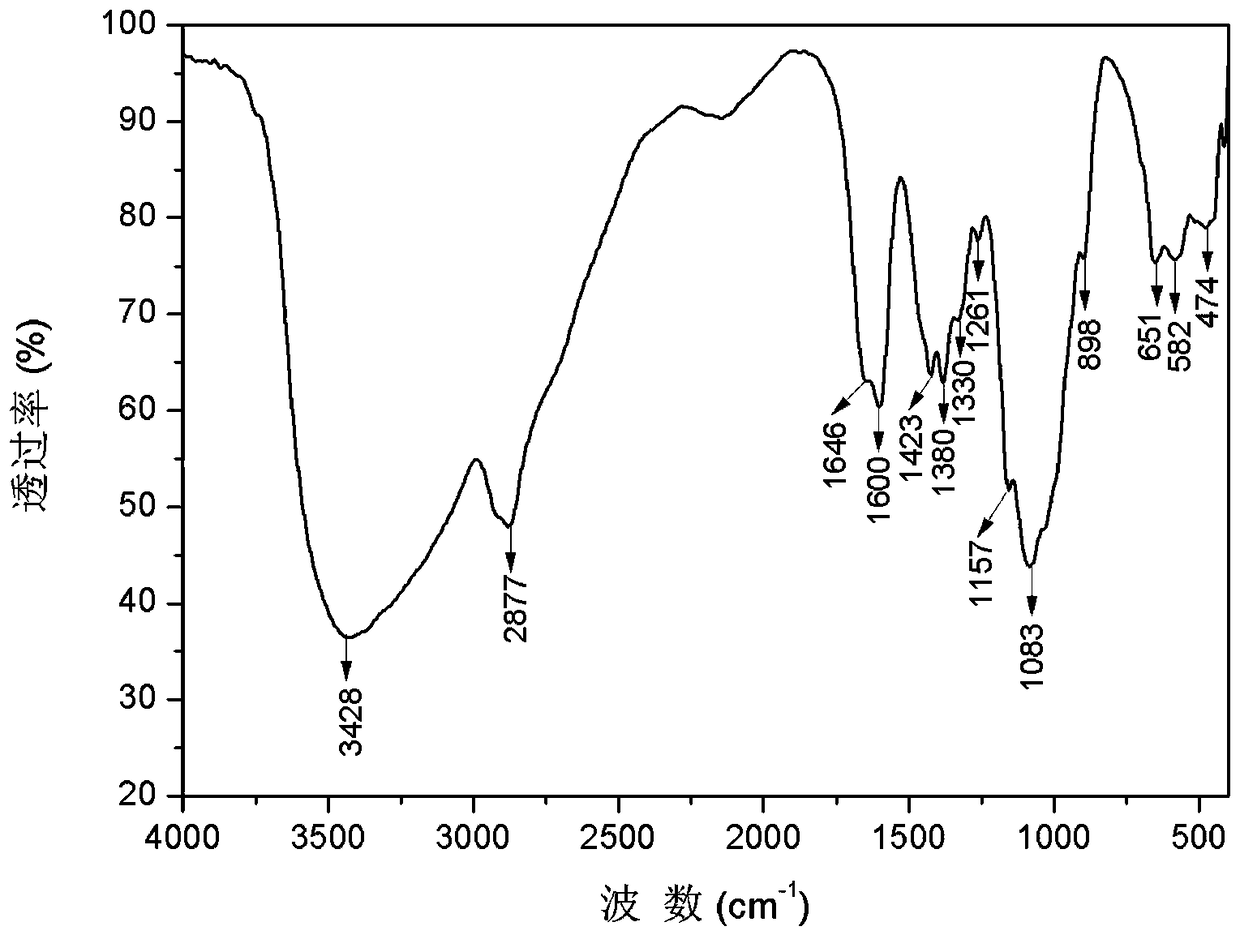

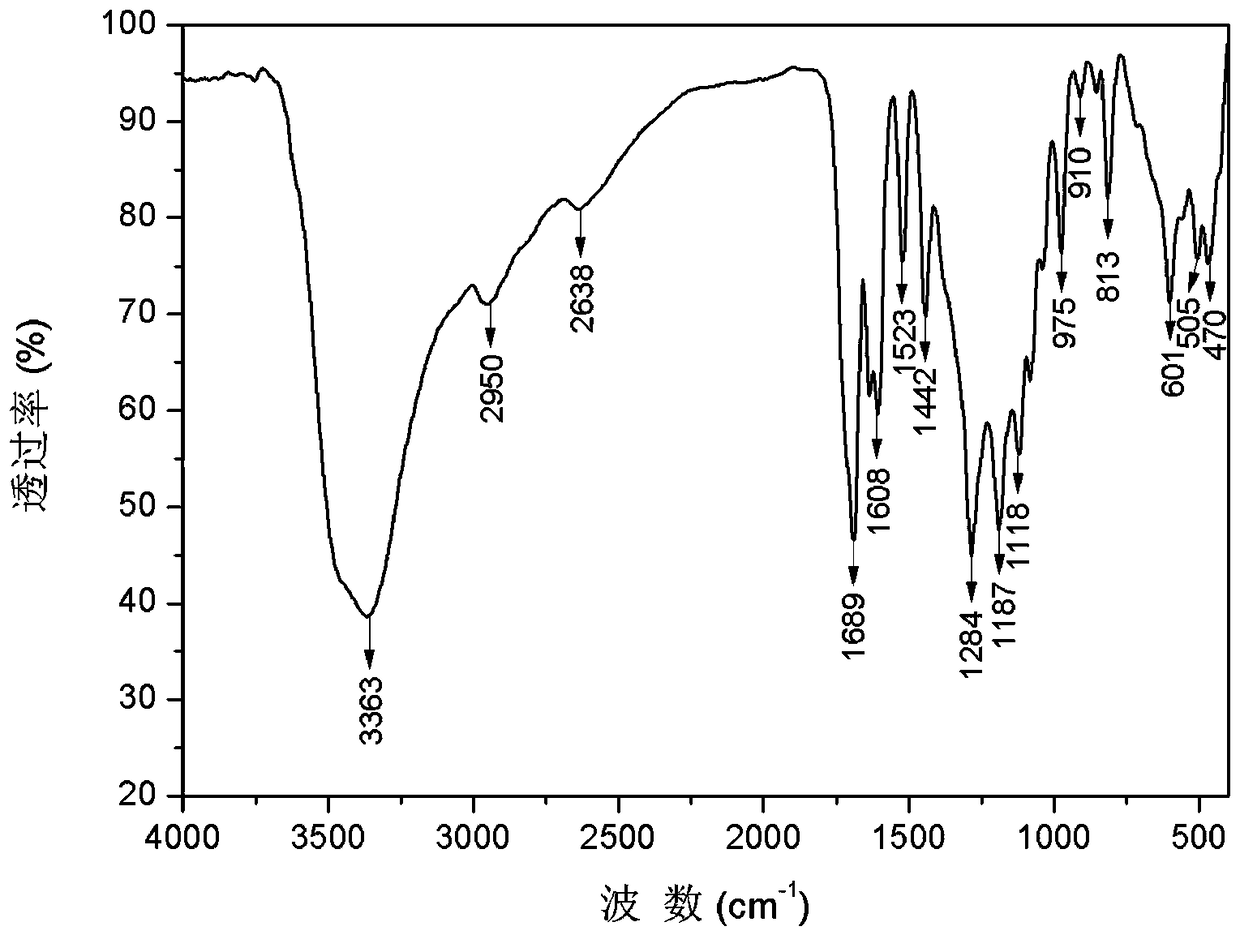

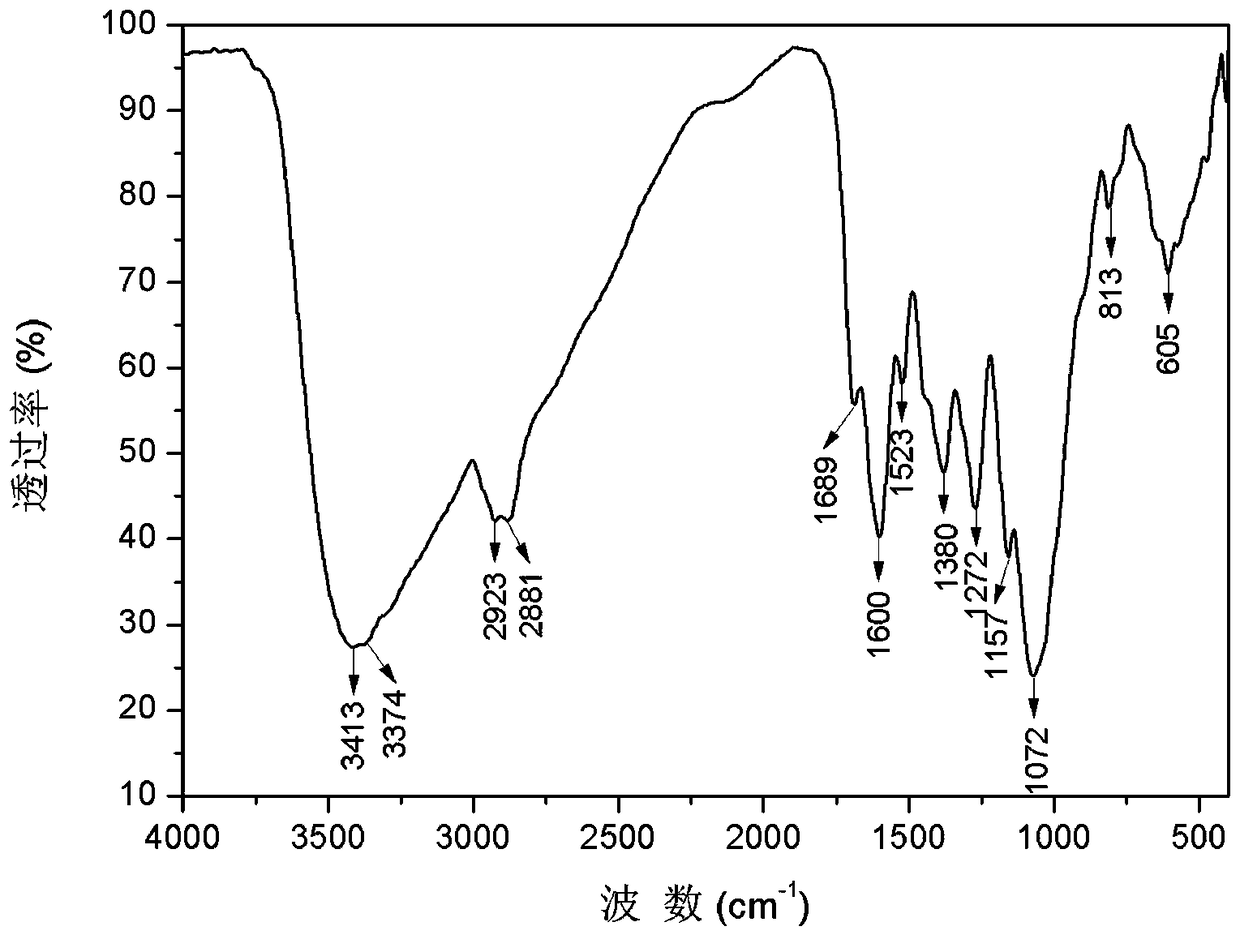

[0029] Weigh 1.77 g of chlorogenic acid (see figure 1 ) in 50 mL of deionized water, heated at 60°C for 10 min to dissolve, and then added 0.80 g of chitosan (see figure 2 ), continue to stir and react at 60°C for 12 h, then precipitate with 200 mL of acetone, wash with absolute ethanol and acetone, and freeze-dry to obtain the chitosan chlorogenic acid salt shown in formula (1) (see image 3 ); wherein, the average degree of aggregation n ranges from 10 to 3000.

Embodiment 2

[0031] The difference from Example 1 is:

[0032] Weigh 3.54 g of chlorogenic acid in 50 mL of deionized water, heat at 70 °C for 10 min to dissolve, then add 0.80 g of chitosan, continue to stir and react at 70 °C for 10 h, then precipitate with 200 mL of acetone, and then separate After washing with absolute ethanol and acetone, and freeze-drying, the chitosan chlorogenic acid salt shown in formula (1) is obtained (see image 3 ); wherein, the average degree of aggregation n ranges from 10 to 3000.

Embodiment 3

[0034] The difference from Example 1 is:

[0035] Weigh 1.77 g of chlorogenic acid in 50 mL of deionized water, heat at 70 °C for 10 min to dissolve, then add 0.80 g of chitosan, continue to stir and react at 70 °C for 10 h, then precipitate with 200 mL of acetone, and then separate After washing with absolute ethanol and acetone, and freeze-drying, the chitosan chlorogenic acid salt shown in formula (1) is obtained (see image 3 ); wherein, the average degree of aggregation n ranges from 10 to 3000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com