Method for carrying out distribution and efficiency optimization control on motor vector control reference current

A technology of reference current and vector control, which is applied in vector control system, motor generator control, electromechanical brake control, etc. It can solve problems such as complex operating conditions, reduced motor utilization, large motor temperature fluctuations, etc., to achieve narrow search range, improve utilization, and reduce the effect of repeating the steps of determining the optimal point search direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

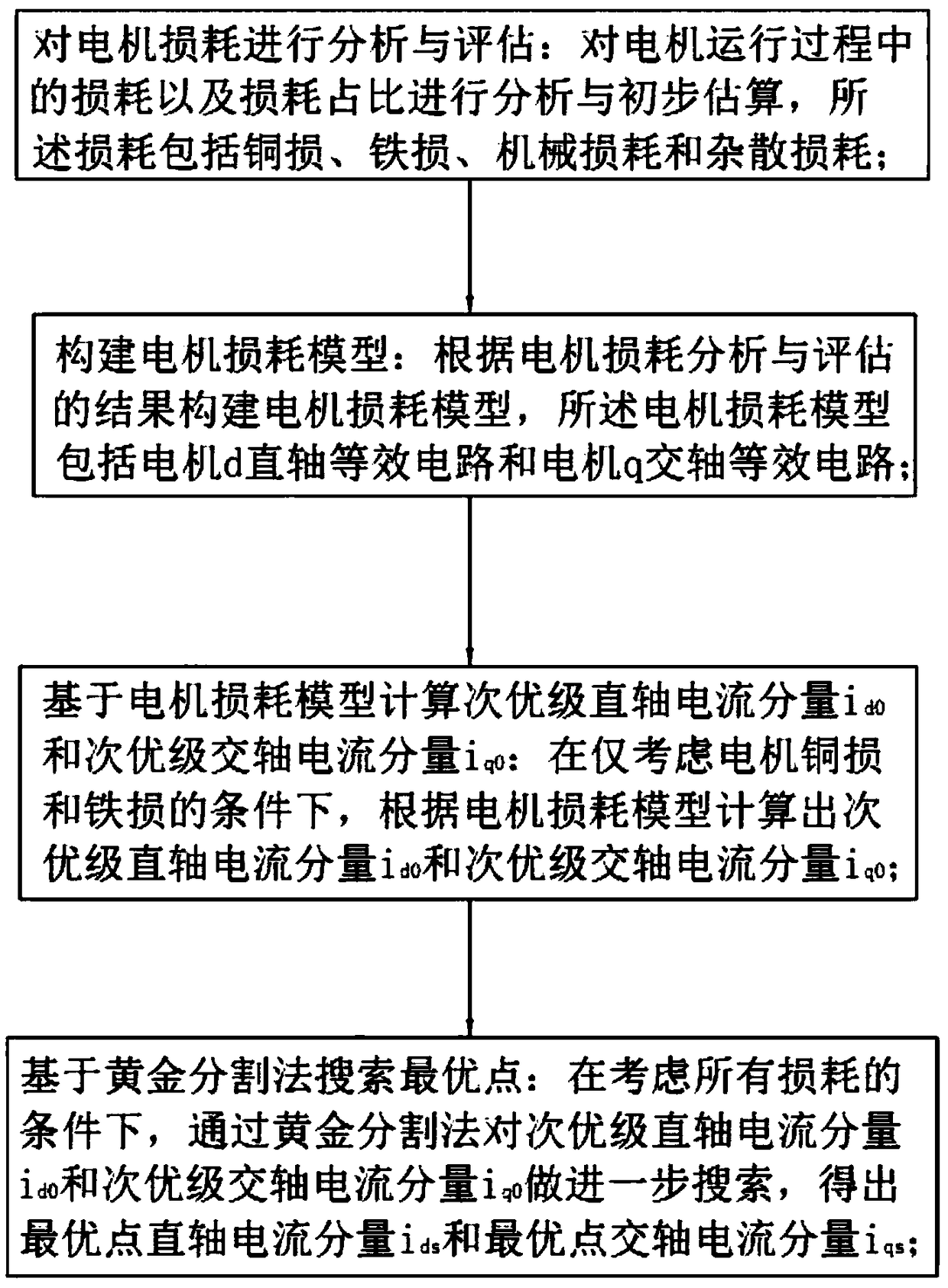

[0034] Embodiment: a method for distributing and optimizing efficiency control of the motor vector control reference current, such as figure 1 shown, including the following steps:

[0035] Step one, analyze and evaluate the motor loss.

[0036] Analyze and preliminarily estimate the loss and loss ratio during the operation of the motor. The loss includes copper loss, iron loss, mechanical loss and stray loss.

[0037] Step 2, build the motor loss model.

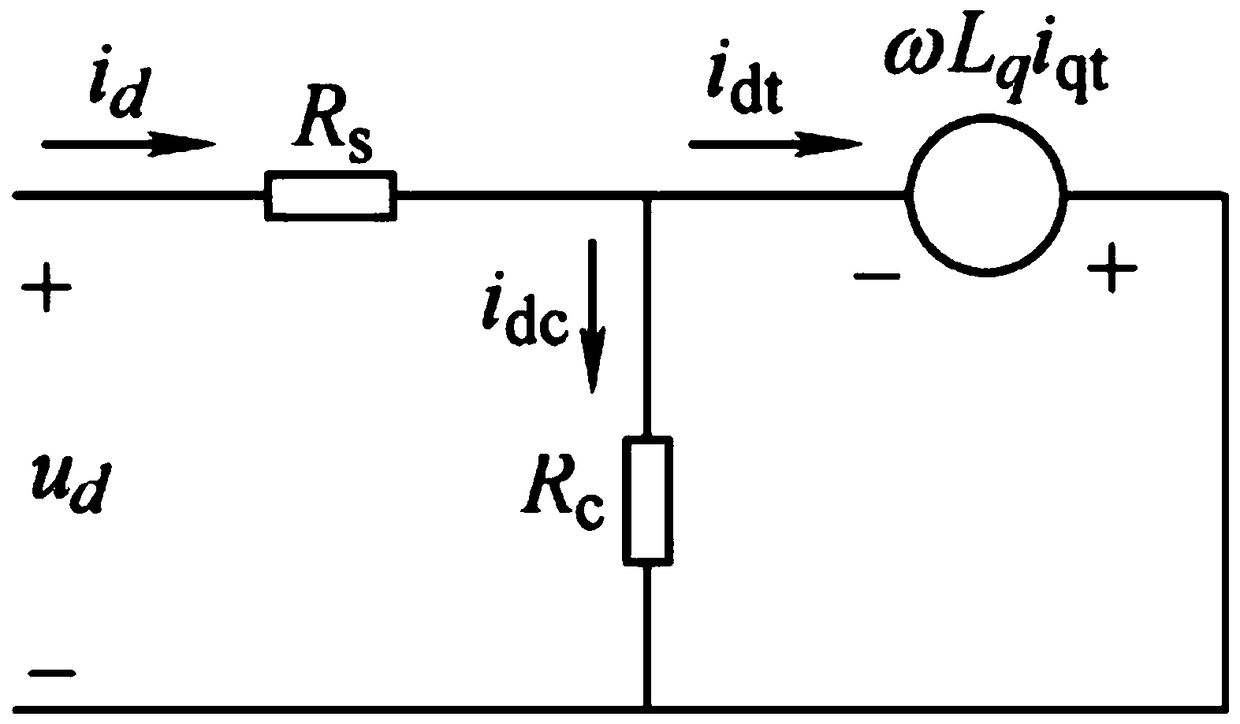

[0038] A motor loss model is constructed according to the results of the motor loss analysis and evaluation, and the motor loss model includes a d-axis equivalent circuit of the motor and a q-axis equivalent circuit of the motor.

[0039] Step 3: Calculate the suboptimal direct-axis current component i based on the motor loss model d0 and the suboptimal quadrature axis current component i q0 . Under the condition of only considering the copper loss and iron loss of the motor, the suboptimal direct-axis current component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com