Straw silage forage fermentation method

A fermentation method and silage technology, applied in the field of forage processing, can solve the problems of reducing the nutritional value of forage, loss of dry matter, and poor stability, and achieve good aerobic stability, reduced loss of dry matter, and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

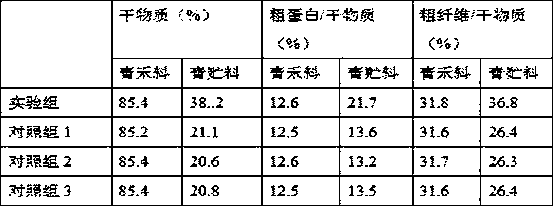

Image

Examples

Embodiment 1

[0025] A method for fermenting straw silage, the specific steps are as follows:

[0026] 1) Weigh 30 parts of straw and 20 parts of forage grass according to weight parts, cut into lengths of 2 cm, add 10 parts of forage additives, mix and stir, lay flat on the ground for drying, and dry until the water content is 50% by weight to make silage material;

[0027] 2) Put the silage into the fermentation tank, lay a layer of waterproof substrate with a thickness of 5cm on the bottom, then pile the silage on top, spray 1 part of forage treatment agent for every 5cm of accumulation;

[0028] 3) Add the mixed bacterial solution to the silage, and the inoculation amount is 50ml of the mixed bacterial solution per kg of forage;

[0029] 4) After mechanically compacting the silage, cover it with a layer of plastic film with a thickness of 1 cm, and then cover it with 20 cm of soil, and carry out sealed fermentation. The temperature in the fermentation tank is 15 ° C, and the fermentati...

Embodiment 2

[0040] A method for fermenting straw silage, the specific steps are as follows:

[0041] 1) Weigh 35 parts of straw and 25 parts of forage grass according to weight parts, cut into lengths of 2 cm, add 15 parts of forage additives, mix and stir, lay flat on the ground for drying, and dry until the water content is 55% by weight to make silage material;

[0042] 2) Put the silage into the fermentation tank, lay a layer of waterproof substrate with a thickness of 7cm on the bottom, then pile the silage on top, and spray 1 part of forage treatment agent for every 7cm of accumulation;

[0043] 3) Add the mixed bacterial solution to the silage, and the inoculum amount is 70ml of the mixed bacterial solution per kg of forage;

[0044] 4) After mechanically compacting the silage, cover it with a layer of plastic film with a thickness of 1 cm, and then cover it with 25 cm of soil, and carry out sealed fermentation. The temperature in the fermentation tank is 17 ° C, and the fermentat...

Embodiment 3

[0055] A method for fermenting straw silage, the specific steps are as follows:

[0056] 1) Weigh 40 parts of straw and 30 parts of forage grass according to weight parts, cut into lengths of 3 cm, add 20 parts of forage additives, mix and stir, lay flat on the ground for drying, and dry until the water content is 60% by weight to make silage material;

[0057] 2) Put the silage into the fermentation tank, lay a layer of waterproof substrate with a thickness of 10cm on the bottom, then stack the silage on top, and spray 2 parts of forage treatment agent for every 10cm of accumulation;

[0058] 3) Add the mixed bacterial solution to the silage, and the inoculation amount is 100ml of the mixed bacterial solution per kg of forage;

[0059] 4) After mechanically compacting the silage, cover it with a layer of plastic film with a thickness of 2 cm, and then cover it with soil for 30 cm, and carry out sealed fermentation. The temperature in the fermentation tank is 20 ° C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com