Protein self-assembly embedding insoluble active material nano product and preparation method thereof

An active substance and self-assembly technology, applied in protein-containing food ingredients, food science, food ingredients, etc., can solve problems that do not conform to the concept of environmental friendliness, are not beneficial to human health, and poor embedding rate, and achieve cost Low, improved water solubility, wide application space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Accurately weigh 1g of soybean 7S protein powder, disperse it in 100g of distilled water (the default density of distilled water is 1.00g / mL), stir continuously at room temperature for 2h, and then place it at 4°C for 12h ( Before adding sodium azide with a mass concentration of 0.02% to the protein dispersion to prevent the growth of microorganisms), the protein is fully hydrated to obtain a soybean 7S protein stock solution with a mass concentration of 1%.

[0037] (2) Add 3g, 6g, 9g, and 12g of urea into 25g of soybean 7S protein storage solution, stir magnetically for 2 hours, and then place it at 4°C for 12 hours to fully denature the protein, and adjust the pH of the solution to 7.0 to A denatured protein solution with a urea concentration of 12% to 48% is obtained.

[0038] (3) Another 3 g, 6 g, 9 g, and 12 g of urea were added to 25 g of distilled water, stirred and dissolved for 1 hour to obtain a urea solution with the same concentration as in step (2). T...

Embodiment 2

[0044] (1) Accurately weigh 2g of soybean 7S protein powder, disperse it in 100g of distilled water (the default density of distilled water is 1.00g / mL), stir continuously at room temperature for 2h, and then place it at 4°C for 12h ( Adding sodium azide with a mass concentration of 0.02% to the protein dispersion to prevent the growth of microorganisms) to fully hydrate the protein to obtain a soybean 7S protein stock solution with a mass concentration of 2%.

[0045] (2) Take 48g of urea and add it to 100g of soybean 7S protein storage solution, stir it magnetically for 2h, then place it at 4°C for 12h at low temperature to fully denature the protein, and adjust the pH of the solution to 7.0 to obtain a urea mass concentration of 48%. denatured protein solution.

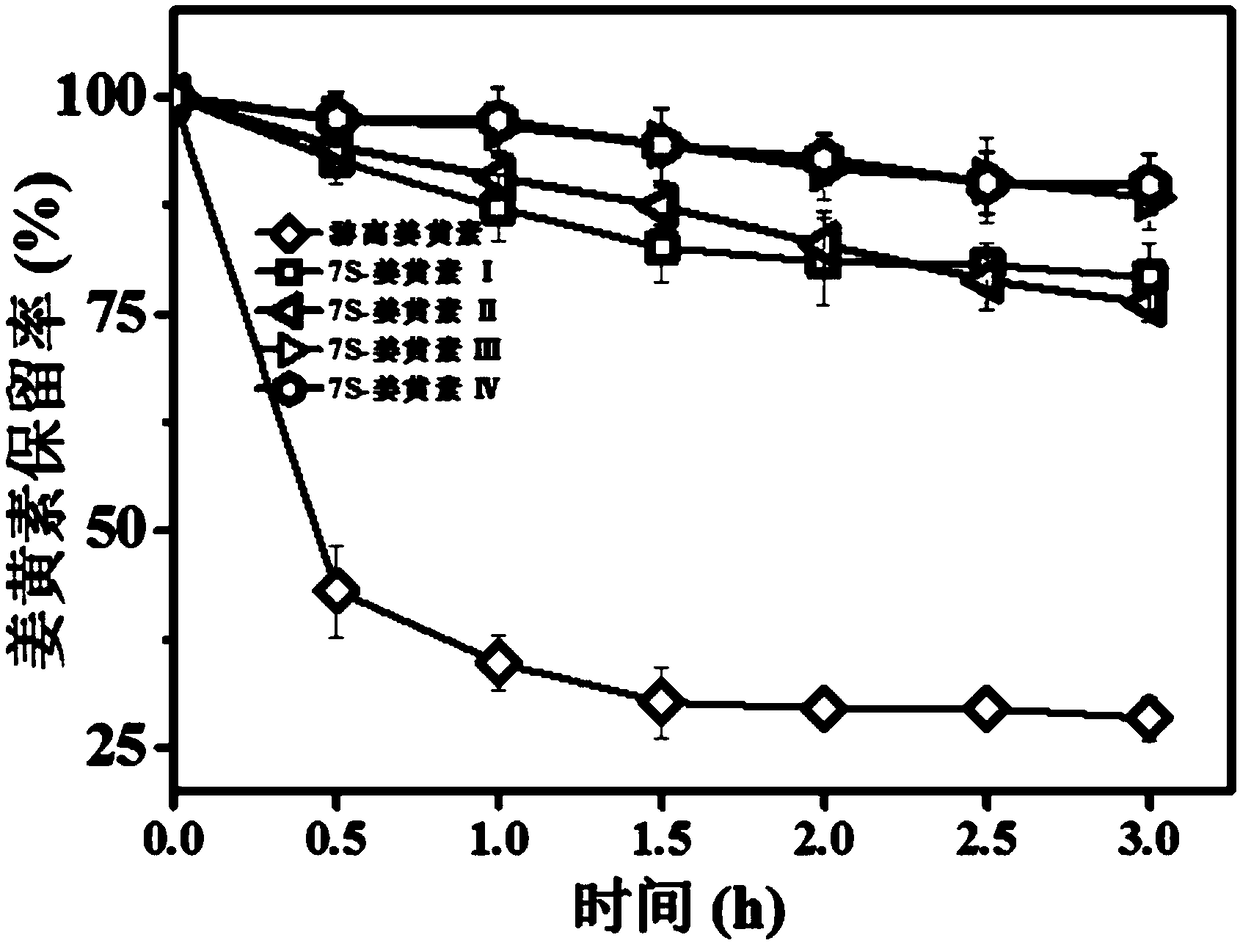

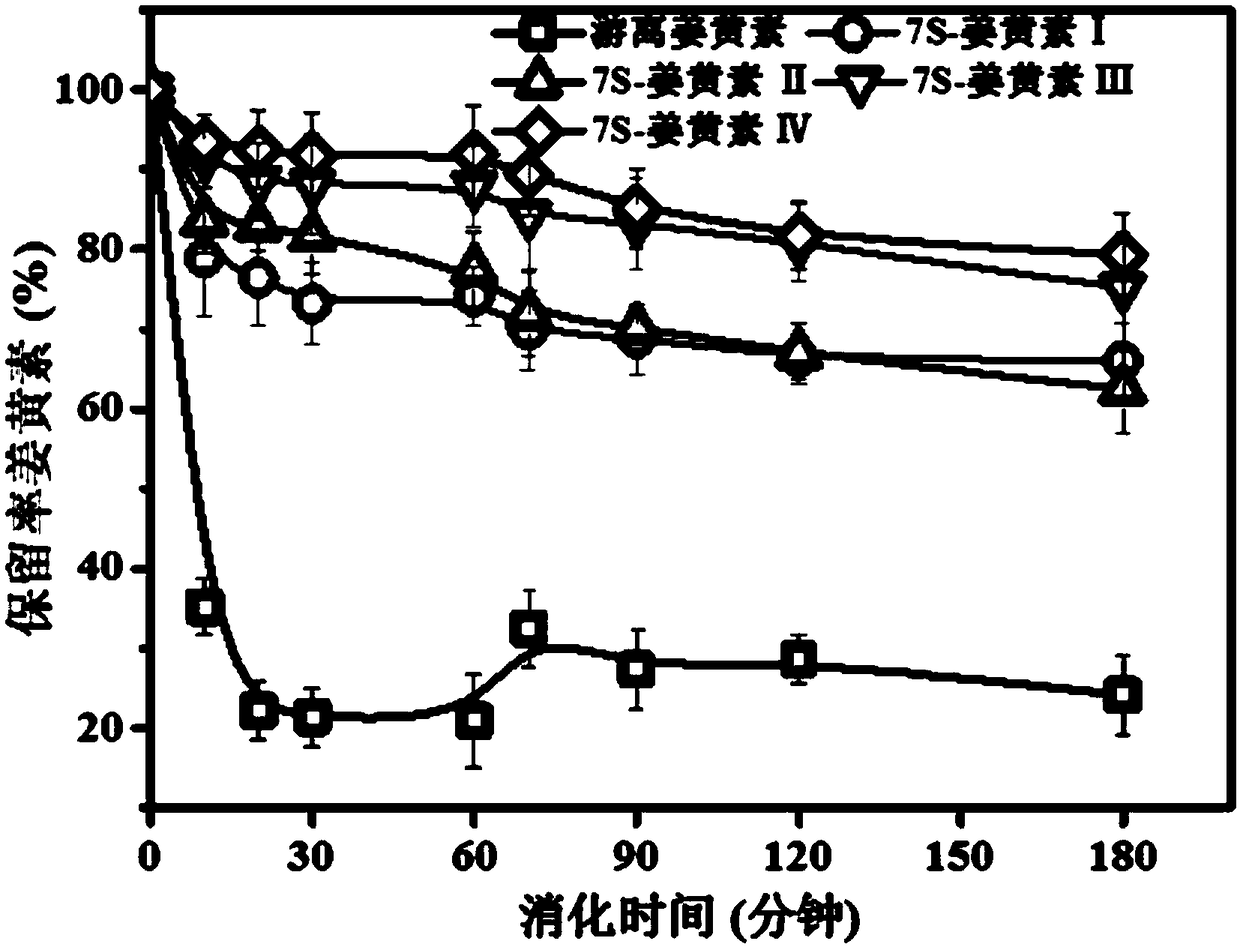

[0046] (3) Add 25 mg, 50 mg, 100 mg, and 150 mg of curcumin to 25 g of denatured protein solution, stir for 4 h in the dark, and then place it at 4°C for 12 h to fully dissolve or adsorb curcumin on the surface of ...

Embodiment 3

[0051] (1) Weigh 2g, 4g, 8g, 16g, and 24g of soybean 7S protein powder respectively, disperse them in 400g of distilled water (the default density of distilled water is 1.00g / mL), stir continuously at room temperature for 2h, and then place Stand at low temperature at 4°C for 12 hours (add sodium azide with a mass concentration of 0.02% to the protein dispersion before standing to prevent the growth of microorganisms) to fully hydrate the protein to obtain mass concentrations of 0.5%, 1%, and 2%, 4%, 6% soybean 7S protein stock solution.

[0052] (2) Add 0 g, 12 g, 24 g, 36 g, and 48 g of urea to 100 g of soybean 7S protein storage solution of various mass concentrations obtained in step (1), stir magnetically for 2 h, and then place it at 4°C for 12 h at low temperature to make the protein Fully denature and adjust the pH of the solution to 7.0 to obtain a denatured protein solution.

[0053] (3) Take 50 mg of curcumin powder and add it to the denatured protein solution of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com