Loading machine pumping valve and casting method thereof

A pumping valve and loader technology, which is used in casting molding equipment, components of a pumping device for elastic fluid, casting molds, etc. The cavity is large and the inner cavity is prone to fracture, which can prevent sintering and sand sticking, increase the strength of the mud core, and have a high pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

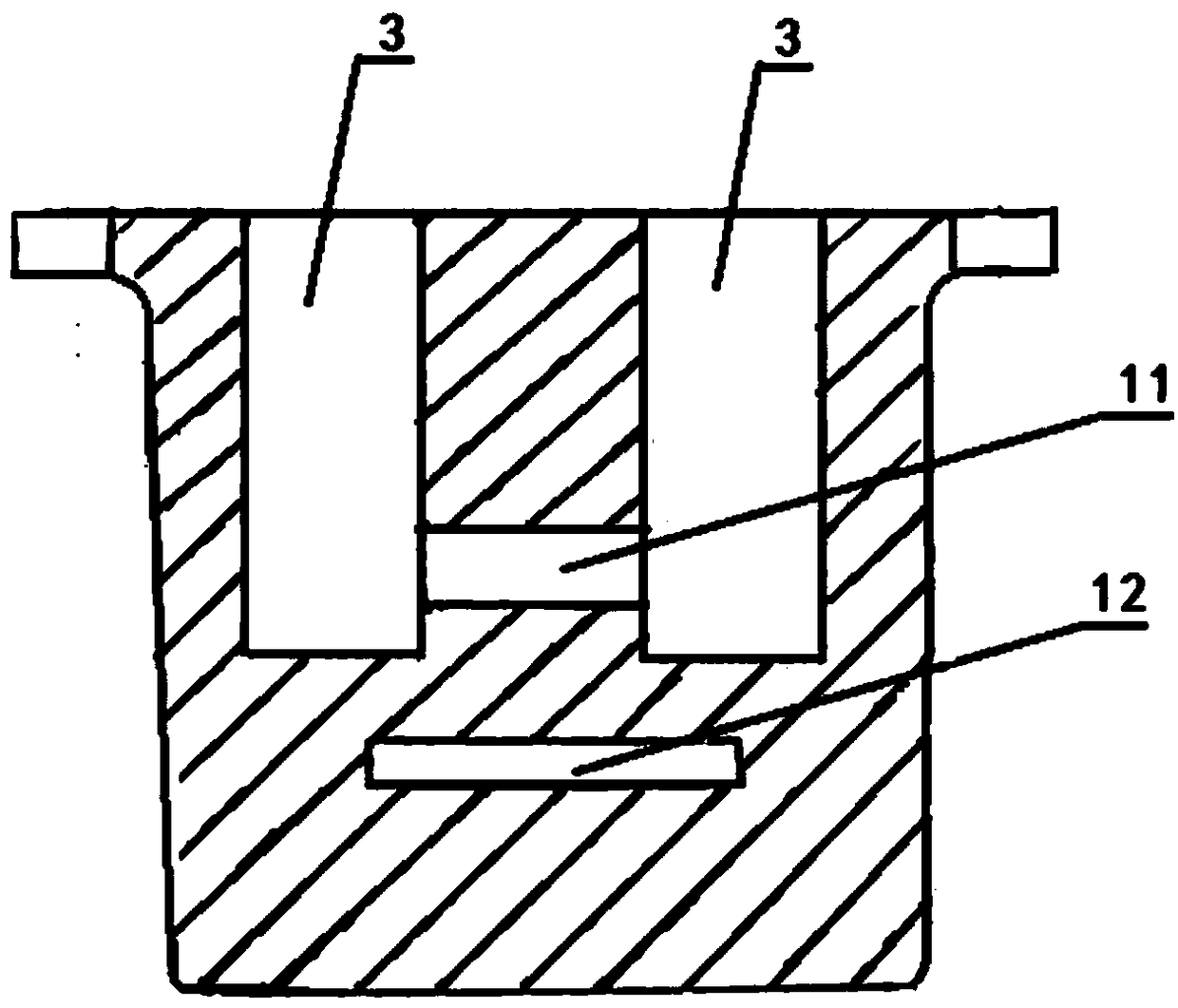

[0035] Embodiment: The present invention provides a casting method for a pumping valve body of a loader, comprising the following steps:

[0036] S1. Check the core-making mold and clean the dirt on the surface of the mold;

[0037] S2. Core making, including core casting, core assembly and core coating, the core is cast with special core sand, and the special core sand is mainly 80% high-strength HAGHD290 core sand, with 20 % of ordinary core sand is supplemented, and the composition of the core sand of the HAGHD290 type is mainly chromite sand, and the core is assembled from a main core and a small core, and the main hole of the main core A steel bar with a diameter of 2mm is placed inside as the core bone. When assembling the main core and the small core, a triangular special core is used to increase the stability and firmness of the core. The core coating process uses HA377 water-based paint and adds A certain amount of graphite powder is used as the coating of the mud co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com