Environment-friendly code-spraying BOPP (Biaxially Oriented Polypropylene) high-speed cigarette packing heat shrinkage film and preparation method thereof

A heat-shrinkable film, environmentally friendly technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of unable to maintain surface printing or coding ability for a long time, achieve smooth packaging process on the machine, excellent antistatic performance, The effect of a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Upper surface layer

[0024] Copolymer polypropylene 94 parts by weight

[0025] Printable anti-blocking masterbatch 6 parts by weight

[0026] The carrier of the printable anti-blocking masterbatch is copolymer polypropylene, the active ingredient is synthetic silica, the concentration is 3wt%, and the particle size is 2um.

[0027] (2) core layer

[0028] 60 parts by weight of homopolymer polypropylene

[0029] 34 parts by weight of stiffening agent masterbatch

[0030] Smooth-antistatic agent masterbatch 6 parts by weight

[0031] The carrier of stiffening agent masterbatch and slip agent-antistatic agent masterbatch is homopolymer polypropylene. The active ingredient of stiffener masterbatch is C 5 The hydrogenated resin, the concentration is 50wt%; the active ingredient of the smooth-antistatic agent masterbatch is cationic antistatic agent ethylamine, and the concentration is 5wt%.

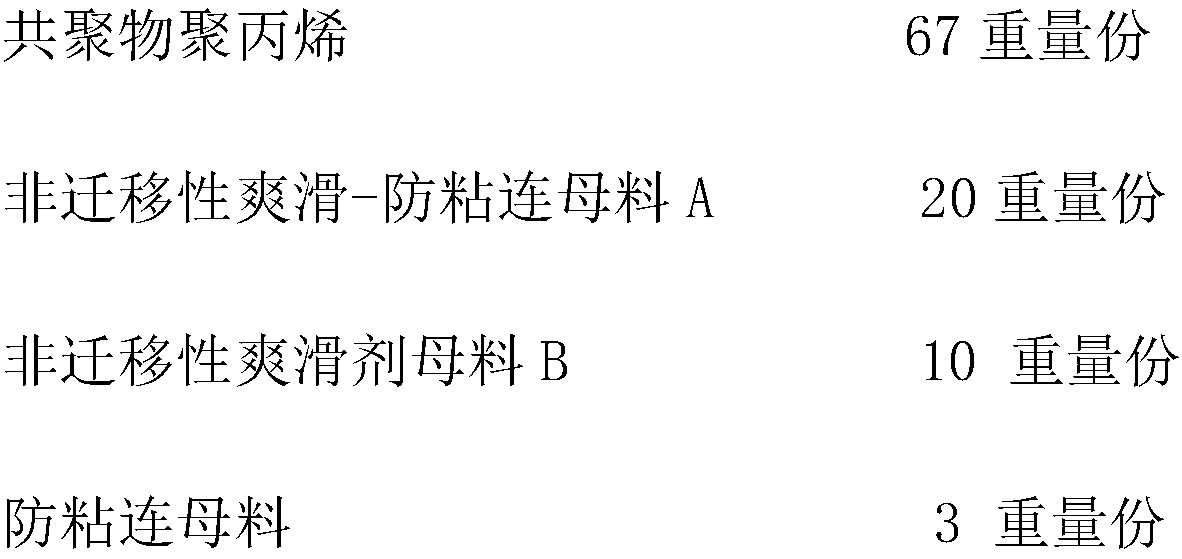

[0032] (3) Lower surface layer

[0033]

[0034] The carrier of no...

Embodiment 2

[0043] According to the following raw material formula:

[0044] (1) Upper surface layer

[0045] Copolymer polypropylene 95 parts by weight

[0046] Printable anti-adhesion masterbatch 5 parts by weight

[0047] The carrier of the printable anti-blocking masterbatch is copolymer polypropylene, the active ingredient is synthetic silica, the concentration is 3wt%, and the particle size is 2um.

[0048] (2) core layer

[0049] 65 parts by weight of homopolymer polypropylene

[0050] Stiffening agent masterbatch 30 parts by weight

[0051] Smooth-antistatic agent masterbatch 5 parts by weight

[0052] The carrier of stiffening agent and slip agent-antistatic agent masterbatch is homopolymer polypropylene. The active ingredient of stiffener masterbatch is C 9 The hydrogenated resin, the concentration is 40wt%; the active ingredient of smooth-antistatic agent masterbatch is non-ionic antistatic agent glyceryl monostearate, the concentration is 5wt%.

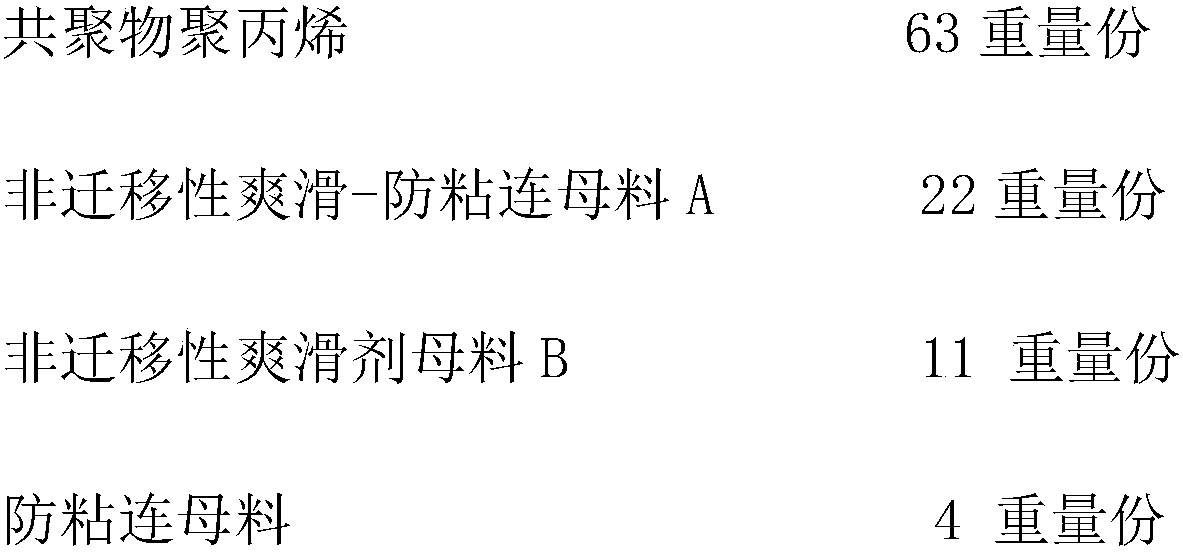

[0053] (3) Lower surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com