Photodynamic self-cleaning textile and preparation method thereof

A self-cleaning, photodynamic technology, applied in textiles and papermaking, animal fibers, fiber processing, etc., can solve problems such as the biological activity of tussah silk and its adverse effects on its wearing performance, environmental hidden dangers of chemical cross-linking agents, and mechanical damage to textiles. , to avoid photocorrosion, good applicability, and strong functional durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

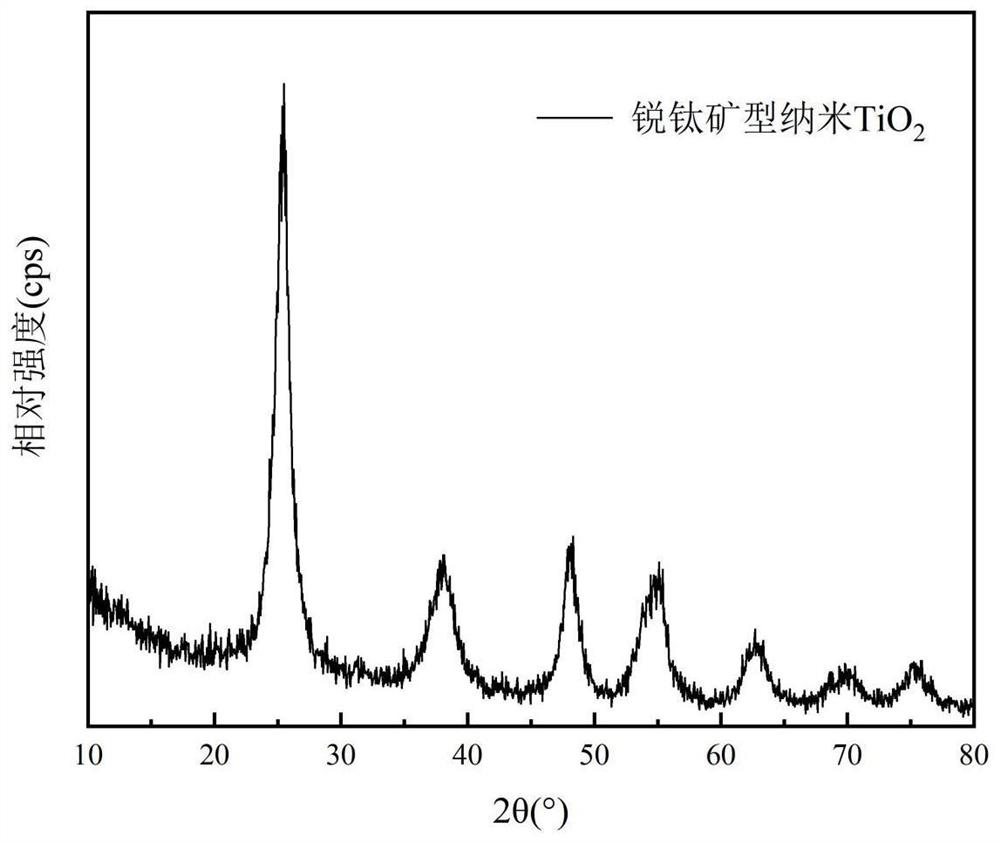

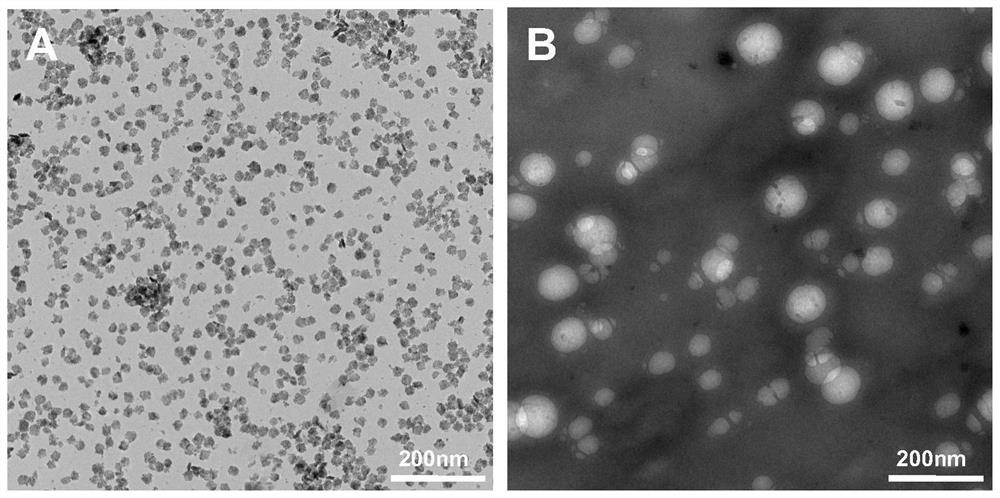

[0038] (1) Add 5 mL of tetraisopropyl titanate to 2 mL of isopropanol, stir at room temperature for 12 minutes to obtain solution A; under rapid stirring, slowly and uniformly drop solution A to 100 mL of 0.1 mol at 50 ° C through a constant pressure funnel / L nitric acid solution, keep stirring for 2 hours, then cool down to room temperature, filter out the precipitate, wash with water, dry in vacuum at 50°C for 24 hours, and grind to obtain anatase nano-TiO 2 ;

[0039] (2) the anatase nano-TiO obtained in step (1) 2 Uniformly disperse in 50mL of acetic acid solution with pH ≤ 4 to make the mass concentration 0.08%, and ultrasonically oscillate for 20min to obtain stable nano-TiO 2 Dispersions;

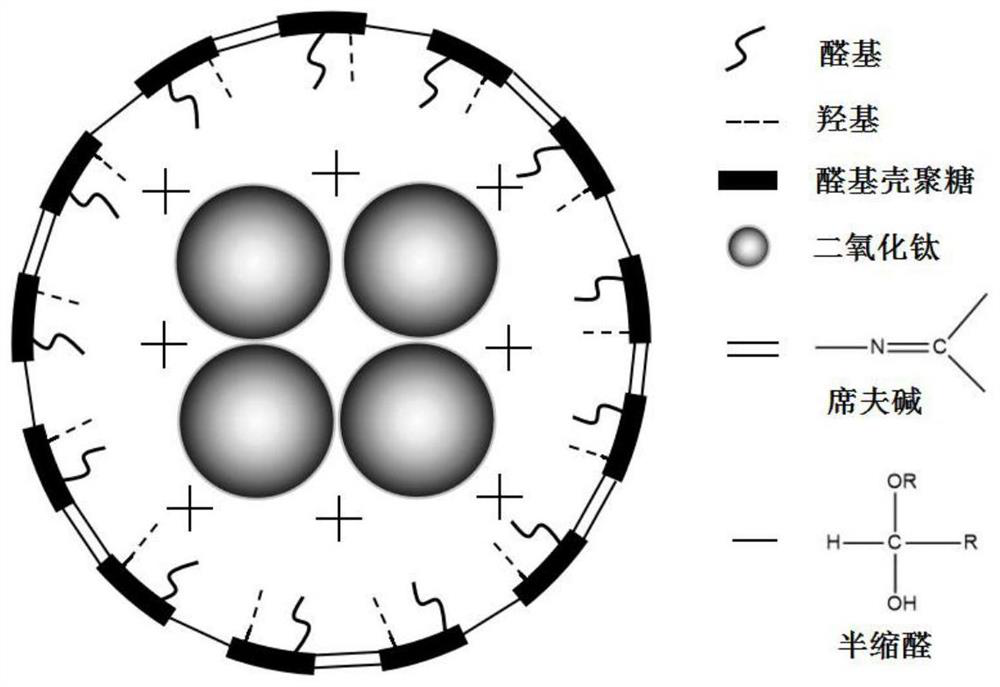

[0040] (3) Add aldehyde-based chitosan (viscosity average molecular weight is 19,400, deacetylation degree is 94.6%, C2, C3 position and C6 position aldehyde group content is 18.37%) in the acetic acid solution that volume concentration is 2%) stirring and dissolving , drop Span ...

Embodiment 2

[0046] (1) Add 8 mL of tetraisopropyl titanate to 4 mL of isopropanol, stir at room temperature for 15 minutes to obtain solution A; under rapid stirring, slowly and uniformly drop solution A to 150 mL of 0.1 mol at 50 ° C through a constant pressure funnel / L nitric acid solution, keep stirring for 3 hours, then cool down to room temperature, filter out the precipitate, wash with water, dry in vacuum at 50°C for 24 hours, and grind to obtain anatase nano-TiO 2 ;

[0047] (2) the anatase nano-TiO obtained in step (1) 2 Uniformly disperse in 50mL of acetic acid solution with pH ≤ 4 to make the mass concentration 0.2%, and ultrasonically oscillate for 25min to obtain stable nano-TiO 2 Dispersions;

[0048] (3) Add aldehyde-based chitosan (viscosity average molecular weight is 13,800, deacetylation degree is 92.5%, C2, C3 position and C6 position aldehyde group content is 22.94%) in the acetic acid solution that volume concentration is 2%) stirring and dissolving , drop Span 8...

Embodiment 3

[0054] (1) Add 8 mL of tetraisopropyl titanate to 4 mL of isopropanol, stir at room temperature for 18 minutes to obtain solution A; under rapid stirring, slowly and uniformly drop solution A to 150 mL of 0.1 mol at 50 ° C through a constant pressure funnel / L nitric acid solution, keep stirring for 3 hours, then cool down to room temperature, filter out the precipitate, wash with water, dry in vacuum at 50°C for 24 hours, and grind to obtain anatase nano-TiO 2 ;

[0055] (2) the anatase nano-TiO obtained in step (1) 2 Uniformly disperse in 50mL of acetic acid solution with pH ≤ 4 to make the mass concentration 0.3%, and ultrasonically oscillate for 30min to obtain stable nano-TiO 2 Dispersions;

[0056] (3) Add aldehyde-based chitosan (viscosity-average molecular weight is 10,900, deacetylation degree is 88.7%, C2, C3 position and C6 position aldehyde group content is 24.38%) in the acetic acid solution that volume concentration is 2%) stirring and dissolving , drop Span 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com